1. VLE Fundamentals

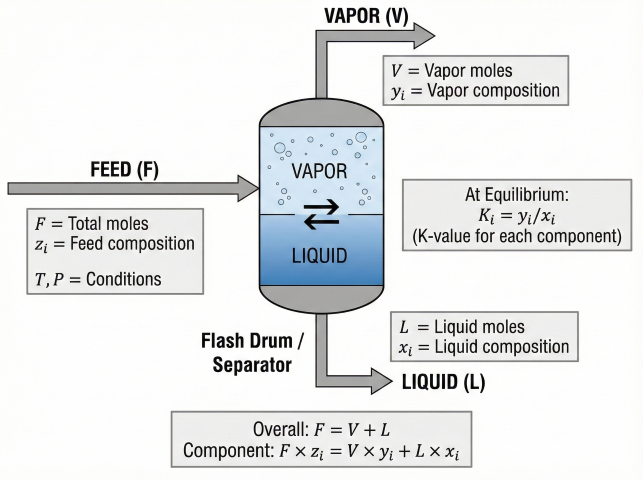

Flash calculations determine how a feed mixture splits into vapor and liquid phases at given conditions. Essential for separator design, distillation, and process simulation.

Material Balance

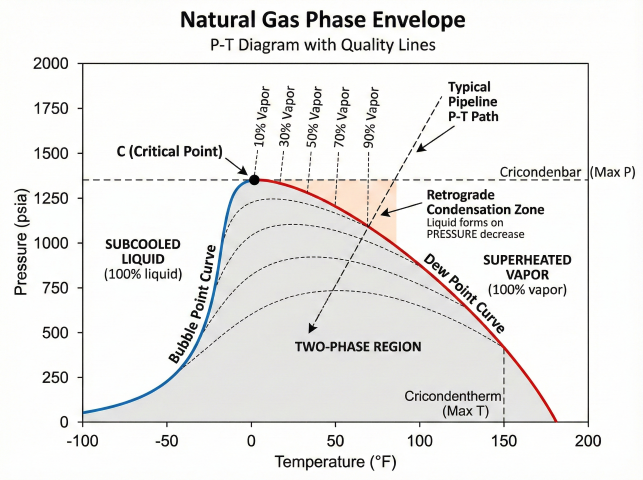

Phase Behavior

| Condition | Result |

|---|---|

| T < Bubble point | All liquid (subcooled) |

| T = Bubble point | First vapor forms |

| Bubble point < T < Dew point | Two-phase (V + L) |

| T = Dew point | Last liquid evaporates |

| T > Dew point | All vapor (superheated) |

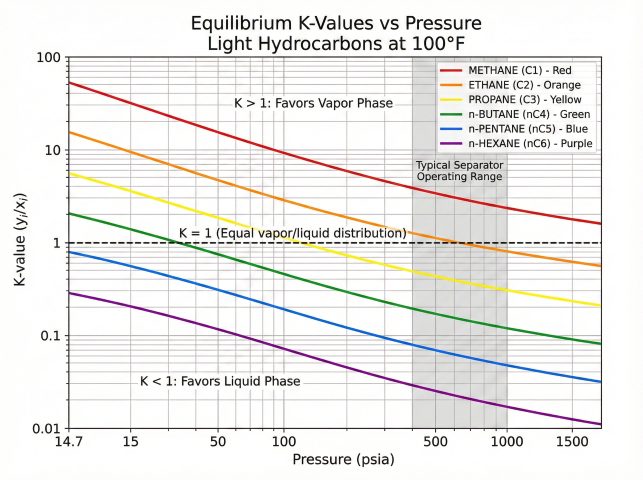

2. K-Values (Equilibrium Ratios)

The K-value relates vapor and liquid compositions at equilibrium:

K-Value Methods

| Method | Equation | Application |

|---|---|---|

| Raoult's Law | K_i = P_i^sat / P | Ideal mixtures, low pressure |

| DePriester Charts | Graphical (T, P) | Light hydrocarbons, quick estimates |

| Wilson Correlation | K_i = (Pc_i/P) × exp(5.37(1+ω)(1-Tc_i/T)) | Hydrocarbons, first approximation |

| Equation of State | φ_i^V / φ_i^L (fugacity) | Most accurate, process simulators |

K-Value Interpretation

- K > 1: Component favors vapor phase (light components)

- K < 1: Component favors liquid phase (heavy components)

- K = 1: Equal distribution (near critical or convergence pressure)

3. Rachford-Rice Equation

The Rachford-Rice equation combines material balance and equilibrium to solve for vapor fraction (V/F):

Solution Steps

- Obtain K-values for all components at T and P

- Check if two-phase: Σz_i×K_i > 1 (bubble) and Σz_i/K_i > 1 (dew)

- Solve Rachford-Rice for V/F

- Calculate compositions: x_i = z_i / (1 + (V/F)(K_i - 1)), y_i = K_i × x_i

- Calculate flows: V = F × (V/F), L = F - V

Convergence Checks

| Test | Result | Conclusion |

|---|---|---|

| Σ(z_i × K_i) < 1 | Below bubble point | All liquid |

| Σ(z_i / K_i) < 1 | Above dew point | All vapor |

| Both sums > 1 | Two-phase region | Solve R-R |

Example: Simple Flash

Feed: 60% C1, 25% C2, 15% C3 (mole) at 500 psia, 50°F

K-values: K_C1 = 4.0, K_C2 = 0.80, K_C3 = 0.25

Check: Σz_i×K_i = 0.6(4)+0.25(0.8)+0.15(0.25) = 2.64 > 1 ✓

Check: Σz_i/K_i = 0.6/4+0.25/0.8+0.15/0.25 = 1.06 > 1 ✓

Two-phase → Solve R-R → V/F ≈ 0.54

x_C1 = 0.6/(1+0.54×3) = 0.22, y_C1 = 4×0.22 = 0.88

4. Flash Types

Isothermal Flash (T-P Flash)

Given: T, P, z_i → Find: V/F, x_i, y_i

- Most common flash calculation

- Direct solution via Rachford-Rice

- Used for separator design

Adiabatic Flash

Given: H_feed, P, z_i → Find: T, V/F, x_i, y_i

- Constant enthalpy (isenthalpic)

- J-T valve expansion

- Requires iteration on T

Bubble Point Calculation

Given: T (or P), z_i, V/F = 0 → Find: P (or T)

- Condition: Σ(z_i × K_i) = 1

- First vapor bubble forms

- y_i = z_i × K_i at bubble point

Dew Point Calculation

Given: T (or P), z_i, V/F = 1 → Find: P (or T)

- Condition: Σ(z_i / K_i) = 1

- Last liquid drop evaporates

- x_i = z_i / K_i at dew point

5. Applications

Production Separator Sizing

- Flash calculation determines V and L flow rates

- Size vessel for residence time and separation efficiency

- Multi-stage separation optimizes liquid recovery

Stabilizer/Deethanizer Feed

- Determine feed phase condition

- Calculate reboiler/condenser duties

- Product composition specifications

Pipeline Flow Assurance

- Predict liquid dropout vs. pressure/temperature

- Locate slug catchers and pig receivers

- Two-phase flow regime determination

References

- GPSA, Section 25 (Flash Calculations)

- Campbell Gas Conditioning and Processing, Vol. 1

- Experiment, Inc. "Phase Equilibria in Hydrocarbon Systems" (Chemical Engineering Progress)

- API Technical Data Book – Petroleum Refining

Ready to use the calculator?

→ Launch Calculator