1. Layout Principles

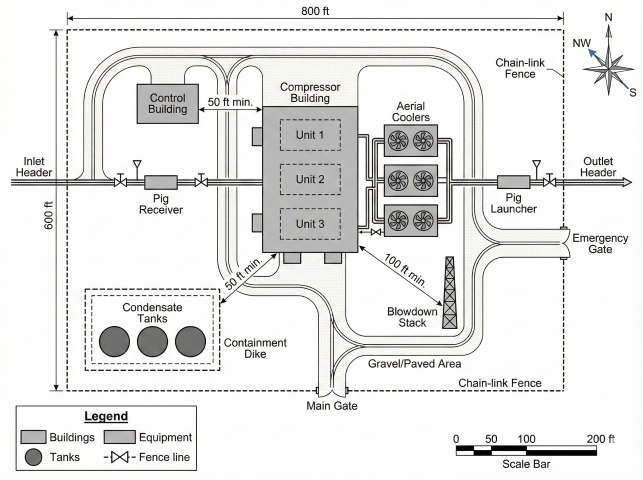

The layout of a compressor station depends on location, proximity to homes and businesses, vegetation, predominant wind direction, and land contour. Equipment placement must minimize impact on the local environment while providing safe and efficient operations.

Primary Design Objectives

- Fire protection: Adequate access for fire fighting equipment and personnel

- Operations: Efficient access for routine operations and monitoring

- Maintenance: Space for equipment removal, laydown, and crane access

- Personnel safety: Protection from hazards and clear evacuation routes

- Equipment protection: Separation from ignition sources and hazardous areas

- Adjacent properties: Prevention of danger or nuisance to neighbors

General Layout Considerations

- Future expansion: The compressor building shall be located to allow addition of future compression and/or gas cooling

- Wind direction: Vents shall be placed so hydrocarbon vapors do not pass over potential ignition sources

- Site security: Local conditions may require increased or decreased spacing from property line

- Adjacent development: Consider current and future proximity of homes, businesses, and public areas

- Terrain: Use natural features for noise screening and drainage

Access Requirements

The facility layout must provide:

- Access to individual equipment for maintenance while adjacent facilities remain in operation

- Sufficient exit doors from compressor building to provide escape from any point

- Emergency vehicle access around the perimeter of major equipment areas

- Crane access for equipment removal and replacement

2. Equipment Spacing Requirements

Minimum spacing requirements provide adequate safety margins for operations, maintenance, fire protection, and emergency response. These distances are based on industry practice and regulatory requirements.

Building Separation Distances

| From | To | Minimum Distance |

|---|---|---|

| Compressor building | Control building | 50 ft |

| Compressor building | Shop/warehouse | 50 ft |

| Compressor building | Boiler building | 50 ft |

| Compressor building | General office building | 50 ft |

Note: Control building should preferably be located on the free air and exhaust side of the compressor building.

Vent and Blowdown Distances

| System | Minimum Distance from Compressor Building |

|---|---|

| Blowdown vent header discharge | 100 ft |

| Compressor unit piping vent system | 100 ft |

| Cranking gas vent header | 100 ft |

Storage Tank Distances

| Equipment | Minimum Distance | From |

|---|---|---|

| Pipeline condensate storage tanks | 50 ft | Any building |

| Pipeline condensate storage tanks | 50 ft | Operating equipment |

| Pipeline condensate storage tanks | 50 ft | Source of ignition |

Property Line Considerations

Distance from facility to property line depends on:

- Type of facility nearest the boundary

- Nature of adjacent property (industrial vs. residential)

- Local noise ordinances and zoning requirements

- Potential for light, odor, and noise impacts

In residential areas, additional space for screening may be required to mitigate light, noise, and odor impacts.

3. Emergency Shutdown (ESD) Requirements

Per 49 CFR 192, each compressor station (except unattended field stations of 1,000 HP or less) must have an emergency shutdown system meeting specific requirements.

ESD System Capabilities

The emergency shutdown system must:

- Block gas out of the station and blow down the station piping

- Discharge gas from blowdown piping at a location where gas will not create a hazard

- Provide means for shutdown of gas compressing equipment, gas fires, and electrical facilities in the vicinity of gas headers

ESD Actuation Points

| Requirement | Specification |

|---|---|

| Number of actuation locations | Minimum 2 locations |

| Location requirement | Outside the gas area of the station |

| Placement (fenced station) | Near exit gates |

| Placement (unfenced station) | Near emergency exits |

| Maximum distance from station | 500 ft from station limits |

| Distance from compressor building | Minimum 25 ft |

Electrical Circuits Exceptions

The following electrical circuits may remain energized during ESD:

- Emergency lighting: Circuits that supply lighting required to assist personnel in evacuating the compressor building and gas header area

- Equipment protection: Circuits needed to protect equipment from damage

Fuel Gas Shutdown

The compressor building fuel gas shutdown system shall have block and bleed valves located outside of the compressor building.

Distribution System Supply: If a compressor station supplies gas directly to a distribution system with no other adequate source available, the ESD system must be designed so it will not function at the wrong time and cause an unintended outage.

Automatic ESD Triggers (Offshore/Inland Navigable Waters)

For platforms located offshore or in inland navigable waters, the ESD must actuate automatically for:

Unattended Compressor Stations:

- Gas pressure reaches MAOP + 15%

- Uncontrolled fire occurs on platform

Compressor Stations in Buildings:

- Uncontrolled fire occurs in building

- Gas concentration reaches 50% or more of LEL in a building with ignition source

4. Noise Considerations

FERC requires noise estimates for any new or modified facility. Noise is often the controlling factor in equipment placement and orientation.

FERC Noise Limits

| Parameter | Limit | Description |

|---|---|---|

| Ldn | 55 dBA | Day-night equivalent sound level at NSA |

| Leq (equivalent) | 48.6 dBA | Continuous equivalent for 24-hour operation |

Note: The 55 dBA Ldn limit applies to station contribution only at noise-sensitive areas (NSAs). Environmental noise from traffic, aircraft, etc. is excluded.

Noise-Sensitive Areas (NSAs)

NSAs include:

- Residences

- Schools

- Hospitals

- Churches

- Playgrounds

- Farms

- Camping facilities

Layout Strategies for Noise Control

- Maximize distance from noise-generating equipment to NSAs

- Consider prevailing wind direction (sound travels farther downwind)

- Use terrain features as natural noise barriers

- Position buildings or trees as noise screens

- Orient equipment exhaust away from NSAs

Noise Abatement Options

| Source | Abatement Method |

|---|---|

| Turbine inlet/exhaust | Additional silencing |

| Gas engine exhaust | Hospital grade silencers |

| High-velocity piping/valves | Sound insulation or burial |

| Aerial coolers | Reduced fan speeds, acoustical hoods |

| Compressor building | Acoustical wall/roof insulation |

Noise Survey Requirements

- New facilities: Baseline survey of environmental noise before construction

- Modified facilities: Survey with existing facilities at full load (avoid unusual/extraneous noise)

- Modeling: Expected noise from additions modeled over baseline

5. Air Emissions

Air emissions must be evaluated early in planning for any horsepower addition or modification. Emission considerations can significantly impact driver selection and project costs.

Emission Evaluation Checklist

- Existing emissions and permit conditions

- Attainment vs. non-attainment area status

- NOx, CO, and unburned hydrocarbon levels

- Anticipated emissions from proposed addition

- Control requirements for acceptable emission levels

- Existing horsepower that can be shut down/removed

- Project timing vs. permit acquisition time

Major Source Thresholds (MST)

| Area Status | MST | Notes |

|---|---|---|

| Attainment | 250 T/yr | Any pollutant |

| Non-attainment (marginal) | 100 T/yr | Varies by pollutant |

| Non-attainment (severe) | 25 T/yr | Most restrictive |

Title V Permit Triggers

| Pollutant | Attainment Area | Non-attainment Area |

|---|---|---|

| NOx | 100 T/yr | 50 or 25 T/yr |

| CO | 100 T/yr | 50 or 25 T/yr |

Typical Driver Emission Levels

| Driver Type | NOx | CO |

|---|---|---|

| Gas turbine (dry low NOx) | 25 ppmvd @ 15% O2 | Varies |

| Clean-burn gas engine | 0.7 g/bhp-hr | 1.9 g/bhp-hr |

| Electric motor | Zero | Zero |

New Source Review: If PTE exceeds MST or Significant Emission Rate (SER), the facility is subject to New Source Review (NSR) and BACT/LAER review. Early involvement of environmental specialists is critical.

6. Driver Selection Impact on Layout

The choice of prime mover/compressor package affects facility layout, spacing requirements, and infrastructure needs.

Common Driver/Compressor Combinations

| Driver | Compressor | Layout Considerations |

|---|---|---|

| Electric motor | Reciprocating | Substation space, cooling requirements |

| Electric motor | Centrifugal | Higher flow, smaller footprint |

| Gas engine | Reciprocating | Exhaust stack, fuel gas system, noise |

| Gas turbine | Centrifugal | Inlet air, exhaust, larger setbacks |

Selection Factors

- Pipeline conditions: Suction/discharge pressures, gas volume, flow variability

- Operating philosophy: Base load vs. swing/peaking service

- Existing equipment: Compatibility with maintenance, spare parts

- Control requirements: Manned vs. remote operation

- Operating costs: Fuel/electricity costs, efficiency

- Installation cost: Package cost plus utilities, buildings, site work

- Delivery time: Compressor package typically longest lead item

- Station location: Neighborhood, environmental constraints, space

- Air emissions: Permit requirements, attainment status

- Noise: Local ordinances, NSA proximity

- Project life: Short life may not justify higher capital cost

General Application Guidelines

- Centrifugal: Preferred for high flow or low compression ratios

- Reciprocating: Preferred for low flow or higher compression ratios

- Electric: Zero site emissions, lower noise, higher efficiency

- Gas-fired: No electrical infrastructure, fuel available on-site

7. Code Requirements

Applicable Regulations & Standards

| Code/Standard | Scope | Authority |

|---|---|---|

| 49 CFR Part 192 | Gas transmission/distribution pipelines | DOT/PHMSA (Federal) |

| FERC Regulations | Interstate gas transmission facilities | FERC (Federal) |

| NFPA 30 | Flammable liquids storage | Industry standard |

| NFPA 70 (NEC) | Electrical installations | Industry standard |

| API RP 500/505 | Electrical area classification | Industry standard |

| State/Local codes | Building, fire, zoning | Varies by jurisdiction |

Key Regulatory Requirements

- ESD system: Required for stations >1,000 HP per 49 CFR 192

- Noise limit: 55 dBA Ldn at NSA per FERC

- Air permits: Required based on PTE vs. thresholds

- Hazardous area classification: Per API RP 500/505

- Fire protection: Per NFPA and local requirements

Summary: Minimum Spacing Quick Reference

| Item | Minimum Distance |

|---|---|

| Control/office building from compressor building | 50 ft |

| Condensate tanks from buildings/equipment | 50 ft |

| Blowdown/vent discharge from compressor building | 100 ft |

| ESD actuation from compressor building | 25 ft (minimum) |

| ESD actuation from station limits | 500 ft (maximum) |

References

- 49 CFR Part 192 – Transportation of Natural Gas by Pipeline (DOT/PHMSA)

- 18 CFR Part 380 – FERC Environmental Review Regulations

- API RP 500 – Classification of Locations for Electrical Installations

- API RP 505 – Classification of Locations for Electrical Installations (Zone System)

- NFPA 30 – Flammable and Combustible Liquids Code

- NFPA 70 – National Electrical Code

- ASME B31.8 – Gas Transmission and Distribution Piping Systems

Ready to use the calculator?

→ ESD System Design Fundamentals