1. Overview & Purpose

HAZOP (Hazard and Operability Study) is a structured, systematic examination technique for identifying potential hazards and operability problems in process facilities. Originally developed by ICI in the 1960s, HAZOP is now a global standard for process safety analysis.

Primary objective

Hazard identification

Identify credible deviations from design intent that could lead to hazards.

Secondary objective

Operability issues

Identify conditions that prevent efficient operation but may not be hazardous.

Design phase

Detailed engineering

Conducted when P&IDs are 60-90% complete; early enough to influence design.

Revalidation

Every 5 years

OSHA PSM requires revalidation or update for process changes.

When HAZOP is Required

| Regulation/Standard | Requirement | Applicability |

|---|---|---|

| OSHA 29 CFR 1910.119 | Process Hazard Analysis (PHA) | Facilities with threshold quantities of hazardous chemicals |

| EPA RMP (40 CFR 68) | Hazard assessment and prevention | Facilities that could affect public with chemical release |

| IEC 61882 | HAZOP methodology standard | International standard for HAZOP studies |

| API RP 750 | Management of process hazards | Refining and petrochemical facilities |

| CCPS Guidelines | HAZOP best practices | Chemical process industry guidance |

HAZOP vs. Other PHA Methods

| Method | Application | Advantages | Limitations |

|---|---|---|---|

| HAZOP | Continuous processes, complex systems | Systematic, thorough, captures subtle deviations | Time-consuming, requires P&IDs |

| What-If/Checklist | Simpler processes, existing facilities | Faster, less resource-intensive | Less systematic, relies on team experience |

| FMEA (Failure Mode & Effects) | Equipment-centric analysis | Good for single components, reliability focus | Doesn't capture process interactions well |

| LOPA (Layer of Protection) | Consequence scenarios from HAZOP | Quantifies risk, determines SIL requirements | Requires prior HAZOP to identify scenarios |

HAZOP Principles

- Design intent: Every process parameter has an intended operating condition; deviations from intent are examined

- Guide words: Structured keywords (MORE, LESS, NO, REVERSE, etc.) prompt deviation thinking

- Systematic examination: Every line, equipment item, and parameter is reviewed methodically

- Multidisciplinary team: Process, operations, maintenance, safety, and instrumentation expertise required

- Brainstorming with structure: Creative thinking guided by systematic framework

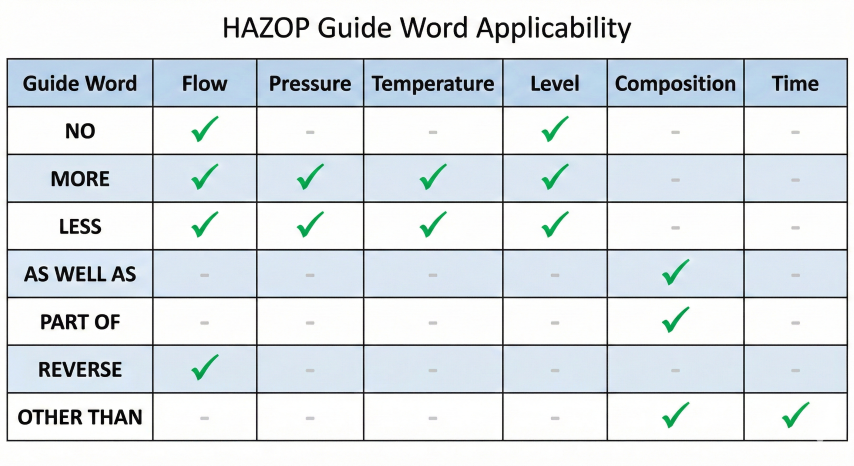

2. Guide Word Technique

Guide words are simple keywords applied to process parameters to stimulate thinking about possible deviations from normal operation.

Standard HAZOP Guide Words

| Guide Word | Meaning | Example Deviations |

|---|---|---|

| NO / NOT / NONE | Complete negation of design intent | No flow, no pressure, no level, no reaction |

| MORE / HIGH | Quantitative increase | Higher flow, pressure, temperature, level, concentration |

| LESS / LOW | Quantitative decrease | Lower flow, pressure, temperature, level, concentration |

| AS WELL AS | Additional activity or component | Contamination, extra phase (vapor/liquid), impurities |

| PART OF | Partial or selective operation | Wrong composition, missing component, incomplete reaction |

| REVERSE / OPPOSITE | Opposite of intent | Backflow, reverse reaction, wrong direction |

| OTHER THAN / INSTEAD OF | Different from design intent | Wrong material, startup/shutdown modes, maintenance activities |

| EARLY / LATE | Timing deviation | Premature action, delayed response, sequence error |

Process Parameters

Guide words are applied to specific process parameters:

- Flow: Rate, direction, composition (MORE flow, NO flow, REVERSE flow)

- Pressure: Absolute pressure, differential pressure (HIGH pressure, LOW pressure)

- Temperature: Process temperature, heating/cooling duty (HIGH temperature, LESS heat)

- Level: Liquid level in vessels, drums, tanks (HIGH level, NO level)

- Composition: Chemical concentration, purity, contamination (AS WELL AS impurity, PART OF component missing)

- Phase: Vapor, liquid, solid state (AS WELL AS vapor in liquid line, OTHER THAN two-phase)

- Time: Reaction time, residence time, batch duration (EARLY termination, LATE start)

- Sequence: Step order in batch operations (REVERSE sequence, EARLY step)

Deviation Generation Examples

Advanced Guide Word Applications

| Scenario Type | Guide Word Combination | Example |

|---|---|---|

| Batch operations | EARLY, LATE, PART OF | EARLY termination of reaction (insufficient conversion) |

| Instrumentation | NO, REVERSE, OTHER THAN | NO signal from transmitter (instrument failure) |

| Utilities | NO, LESS | NO cooling water (loss of utility) |

| Maintenance mode | OTHER THAN, PART OF | OTHER THAN normal operation (valve left closed after maintenance) |

| Control system | REVERSE, MORE, LESS | REVERSE control action (controller in manual, wrong direction) |

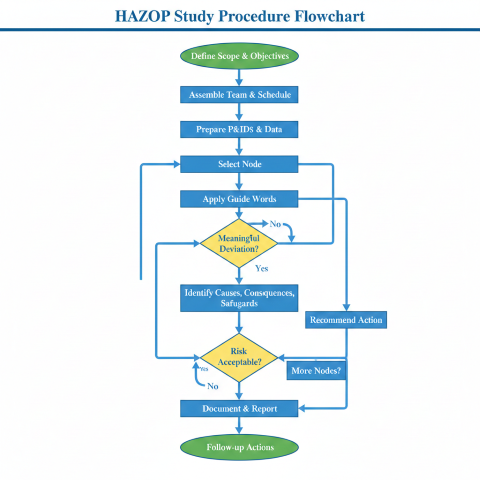

3. HAZOP Procedure

A systematic, step-by-step approach ensures thorough coverage and consistent documentation.

Pre-Study Preparation

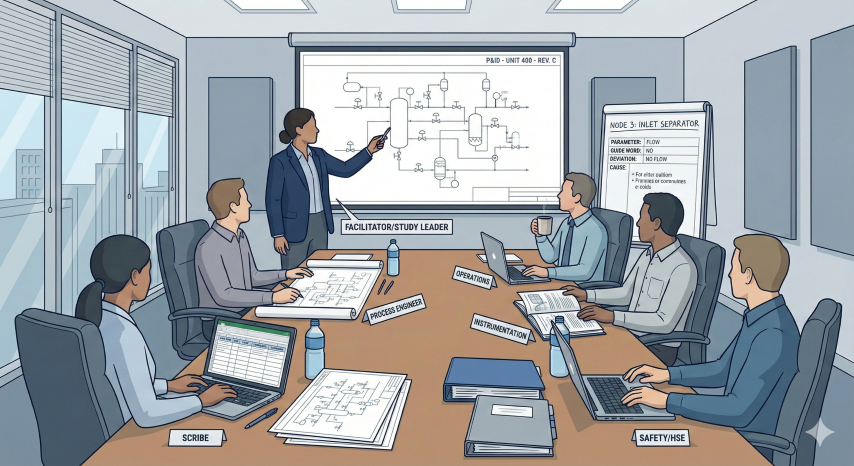

Team Roles and Responsibilities

| Role | Responsibility | Required Background |

|---|---|---|

| Facilitator/Leader | Lead study, apply guide words, keep on schedule | HAZOP training, facilitation skills, process safety knowledge |

| Scribe/Recorder | Document findings, capture actions | Good organizational skills, HAZOP software proficiency |

| Process Engineer | Explain design intent, evaluate process consequences | Detailed process knowledge, mass/energy balance expertise |

| Operations Representative | Describe operating practices, identify operability issues | Field operating experience, knowledge of similar units |

| Maintenance Engineer | Assess equipment failure modes, maintainability | Mechanical/reliability engineering, failure analysis |

| Instrument/Control Engineer | Evaluate instrumentation, control system responses | Control system design, instrument failure modes |

| Safety Specialist | Assess safety consequences, safeguard adequacy | Process safety, hazard evaluation, regulations |

HAZOP Study Steps

Example HAZOP Worksheet Entry

| Node | Guide Word | Deviation | Causes | Consequences | Safeguards | Risk | Actions |

|---|---|---|---|---|---|---|---|

| P-101 discharge | NO | No flow from feed pump | Pump trip on low suction P, power failure, mechanical failure | Column feed interruption, possible tube overheating in reboiler | Low flow alarm FAL-101, auto-start backup pump, reboiler low-low level shutdown | M | Verify backup pump auto-start logic (Owner: Controls, Due: 2024-06-15) |

| V-201 | HIGH | High pressure in separator | PSV-201 fails to open, downstream blockage, thermal expansion | Vessel rupture, potential fire/explosion, fatalities | PSV-201 (500 psig set), PAH-201 alarm at 450 psig, vessel MAWP 600 psig | H | Verify PSV sizing for blocked outlet case; consider adding second PSV (Owner: Process, Due: 2024-06-30) |

Node Selection Strategy

- Equipment-based: Each major equipment item is a node (vessels, pumps, compressors)

- Line-based: Process lines between equipment (P-101 discharge to V-201 inlet)

- Function-based: Logical process function (feed preparation, reaction section, separation)

- Hybrid approach: Combination of above based on complexity

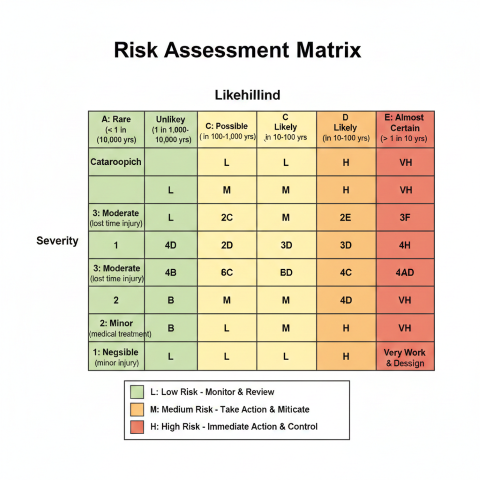

4. Risk Ranking & Consequence Assessment

Risk ranking helps prioritize HAZOP findings and focus resources on high-consequence scenarios.

Risk Matrix Approach

Risk Matrix (5×5)

| Severity → Likelihood ↓ |

1 Negligible |

2 Minor |

3 Moderate |

4 Major |

5 Catastrophic |

|---|---|---|---|---|---|

| E (Very likely) | M | H | H | VH | VH |

| D (Likely) | L | M | H | H | VH |

| C (Possible) | L | M | H | H | VH |

| B (Unlikely) | L | L | M | H | H |

| A (Very unlikely) | L | L | L | M | H |

Risk level definitions:

- VH (Very High): Unacceptable; requires immediate action to reduce risk

- H (High): Requires action to reduce risk; management attention needed

- M (Medium): Review and consider risk reduction; monitor

- L (Low): Acceptable with existing safeguards; no action required

Consequence Categories for Midstream Facilities

| Category | Safety | Environmental | Financial |

|---|---|---|---|

| 1 - Negligible | First aid injury | < 1 bbl spill, on-site only | < $10k loss |

| 2 - Minor | Medical treatment, no lost time | 1-10 bbl spill, contained on-site | $10k-$100k loss |

| 3 - Moderate | Lost-time injury, single person | 10-100 bbl spill, potential off-site | $100k-$1M loss |

| 4 - Major | Permanent disability or multiple injuries | 100-1000 bbl spill, confirmed off-site impact | $1M-$10M loss |

| 5 - Catastrophic | Single fatality or multiple serious injuries | > 1000 bbl spill, major environmental damage | > $10M loss or facility destruction |

Safeguard Effectiveness

When evaluating risk, credit is given only to effective safeguards:

| Safeguard Type | Examples | Typical Risk Reduction |

|---|---|---|

| Passive devices | Relief valves, rupture discs, check valves, dikes | 10-100× (PFD 0.01-0.1) |

| Active devices (non-SIS) | Basic alarms, DCS shutdowns, mechanical trips | 5-10× (PFD 0.1-0.2) |

| Safety Instrumented Systems (SIS) | SIL-rated interlocks and shutdowns | 10-10,000× depending on SIL (SIL 1: 10-100×, SIL 2: 100-1000×, SIL 3: 1000-10,000×) |

| Administrative controls | Procedures, training, inspections, permits | 1-5× (limited credit in HAZOP) |

Action Item Prioritization

5. Documentation & Follow-Up

Comprehensive documentation and action tracking are essential for HAZOP effectiveness and regulatory compliance.

Required Documentation (IEC 61882)

| Document | Content | Retention |

|---|---|---|

| HAZOP Report | Executive summary, methodology, team composition, findings summary | Life of facility |

| HAZOP Worksheets | Detailed node-by-node analysis with all deviations, causes, consequences, safeguards, actions | Life of facility |

| Action Item Register | All actions with owner, due date, priority, status tracking | Until all actions closed + 5 years |

| P&IDs (marked-up) | P&IDs with nodes identified and action items annotated | Until superseded by updated drawings |

| Attendance Records | Team member sign-in sheets for each session | Life of facility |

| Meeting Minutes | Key decisions, assumptions, deferred items | Life of facility |

HAZOP Report Structure

Action Item Tracking

Effective action tracking ensures HAZOP findings translate into risk reduction:

| Field | Description | Example |

|---|---|---|

| Action ID | Unique identifier | HAZOP-2024-001 |

| Node | Process location | V-201 (HP separator) |

| Deviation | Brief description | High pressure |

| Action Description | Specific task to be completed | Add second PSV (PSV-201B) sized for blocked outlet scenario |

| Owner | Person responsible | J. Smith (Process Engineering) |

| Priority | Based on risk level | High (due to VH risk) |

| Due Date | Target completion | 2024-06-30 |

| Status | Open, In Progress, Closed, Deferred | In Progress |

| Closure Notes | Evidence of completion | PSV-201B installed per P&ID rev. 3; relief calc MC-2024-05 filed |

OSHA PSM Compliance (29 CFR 1910.119)

Follow-Up Meeting

Schedule follow-up reviews to track action completion:

- 30-day review: High-priority actions; verify progress on VH/H risk items

- 90-day review: Medium-priority actions; close completed items

- Annual review: Long-term actions; update PHA for any process changes

- Pre-startup review: Verify all actions complete before commissioning (new facilities)

Common HAZOP Action Types

| Action Category | Examples | Typical Implementation |

|---|---|---|

| Add instrumentation | Flow transmitter, temperature alarm, level switch | Design change; install before startup |

| Add safety system | SIS interlock, emergency shutdown, SIL-rated logic solver | Design change; requires SIL verification |

| Add passive protection | Relief valve, rupture disc, check valve, flame arrestor | Design change; install before startup |

| Revise procedure | Update operating procedure, add checklist, training module | Administrative; complete before affected operation |

| Perform study/analysis | Relief sizing calc, dispersion modeling, LOPA, SIL verification | Engineering deliverable; due before design finalized |

| Design change | Pipe size increase, material upgrade, equipment relocation | Major change; requires MOC if existing facility |

Ready to use the calculator?

→ Launch Calculator