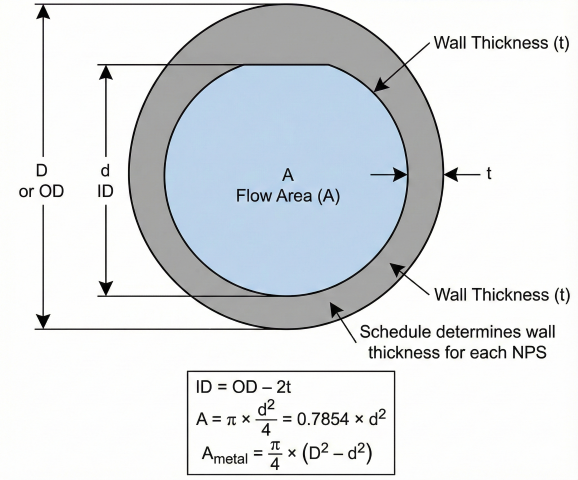

1. Area Calculation

Flow area is the internal cross-sectional area available for fluid flow. It's fundamental to velocity calculations, pressure drop analysis, and equipment sizing.

Basic Formula

Inside Diameter

Metal Area (Pipe Wall)

Ovality Effect (Out-of-Roundness)

2. Velocity Relationships

Flow area connects volumetric flow rate to fluid velocity through the continuity equation.

Continuity Equation

Practical Velocity Formulas

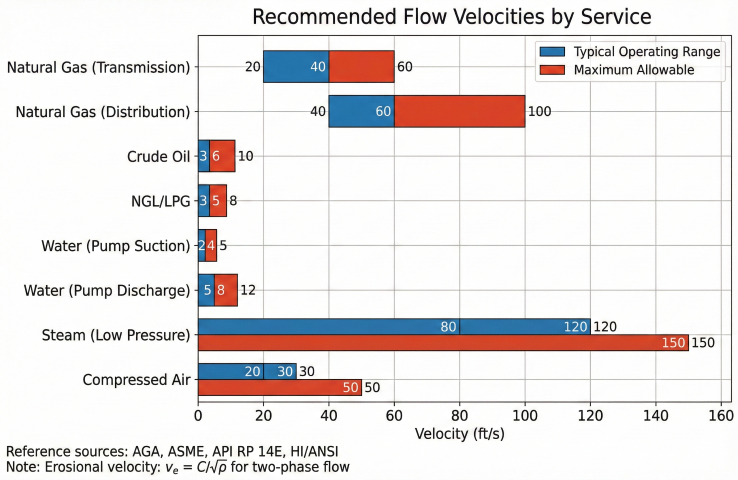

Recommended Velocities

| Service | Typical (ft/s) | Maximum (ft/s) | Reference |

|---|---|---|---|

| Natural gas (transmission) | 20–40 | 60 | AGA, ASME B31.8 |

| Natural gas (distribution) | 40–60 | 100 | ASME B31.8 |

| Crude oil | 3–6 | 10 | API RP 14E |

| NGL/LPG | 3–5 | 8 | GPSA |

| Water (pump suction) | 2–4 | 5 | HI/ANSI |

| Water (pump discharge) | 5–8 | 12 | HI/ANSI |

| Steam (low pressure) | 80–120 | 150 | ASME B31.1 |

| Compressed air | 20–30 | 50 | CAGI |

3. Reference Tables

Standard Pipe Flow Areas

| NPS | OD (in) | Schedule | Wall (in) | ID (in) | Area (in²) | Area (ft²) |

|---|---|---|---|---|---|---|

| 2" | 2.375 | 40 | 0.154 | 2.067 | 3.356 | 0.0233 |

| 4" | 4.500 | 40 | 0.237 | 4.026 | 12.73 | 0.0884 |

| 6" | 6.625 | 40 | 0.280 | 6.065 | 28.89 | 0.2006 |

| 8" | 8.625 | 40 | 0.322 | 7.981 | 50.03 | 0.3474 |

| 10" | 10.750 | 40 | 0.365 | 10.020 | 78.85 | 0.5476 |

| 12" | 12.750 | Std | 0.375 | 12.000 | 113.1 | 0.7854 |

| 16" | 16.000 | Std | 0.375 | 15.250 | 182.7 | 1.269 |

| 20" | 20.000 | Std | 0.375 | 19.250 | 291.0 | 2.021 |

| 24" | 24.000 | Std | 0.375 | 23.250 | 424.6 | 2.948 |

| 30" | 30.000 | Std | 0.375 | 29.250 | 672.0 | 4.666 |

| 36" | 36.000 | Std | 0.375 | 35.250 | 976.0 | 6.778 |

Area Ratios

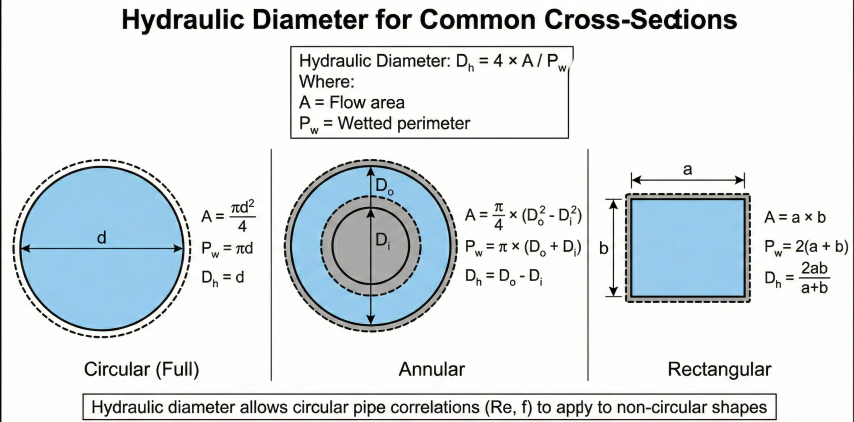

4. Hydraulic Diameter

For non-circular cross-sections or partially filled pipes, hydraulic diameter relates flow area to wetted perimeter for use in friction factor correlations.

Definition

Common Cross-Sections

| Shape | Hydraulic Diameter |

|---|---|

| Circular (full) | D_h = d |

| Circular (half full) | D_h = d |

| Annulus | D_h = D_outer - D_inner |

| Square (side a) | D_h = a |

| Rectangle (a × b) | D_h = 2ab/(a+b) |

| Equilateral triangle | D_h = a/√3 |

Partially Filled Pipe

5. Applications

Reynolds Number

Line Sizing Example

Problem: Size a water line for 500 gpm at max 8 ft/s

Required area:

v = 0.4085 × Q / d²

8 = 0.4085 × 500 / d²

d² = 204.25 / 8 = 25.5

d = 5.05 inches minimum

Select 6" Sch 40:

ID = 6.065 in

v = 0.4085 × 500 / 6.065² = 5.55 ft/s ✓

Orifice and Restriction Areas

Common Uses

- Line sizing: Select pipe diameter for target velocity

- Pump selection: Calculate suction/discharge velocities

- Pressure drop: Velocity head = v²/2g

- Flow measurement: Orifice and venturi sizing

- Heat transfer: Convection coefficient correlations

- Erosion analysis: Check against erosional velocity limits

References

- ASME B36.10M – Welded and Seamless Wrought Steel Pipe (dimensions)

- API 5L – Specification for Line Pipe (tolerances, Table 10 ovality)

- ASTM A530 – General Requirements for Carbon Steel Pipe (tolerances)

- ASME B31.8 – Gas Transmission and Distribution Piping Systems

- API RP 14E – Design and Installation of Offshore Production Piping (erosional velocity)

- Crane TP-410 – Flow of Fluids Through Valves, Fittings, and Pipe

- GPSA

Ready to use the calculator?

→ Launch Calculator