1. Correlation Overview

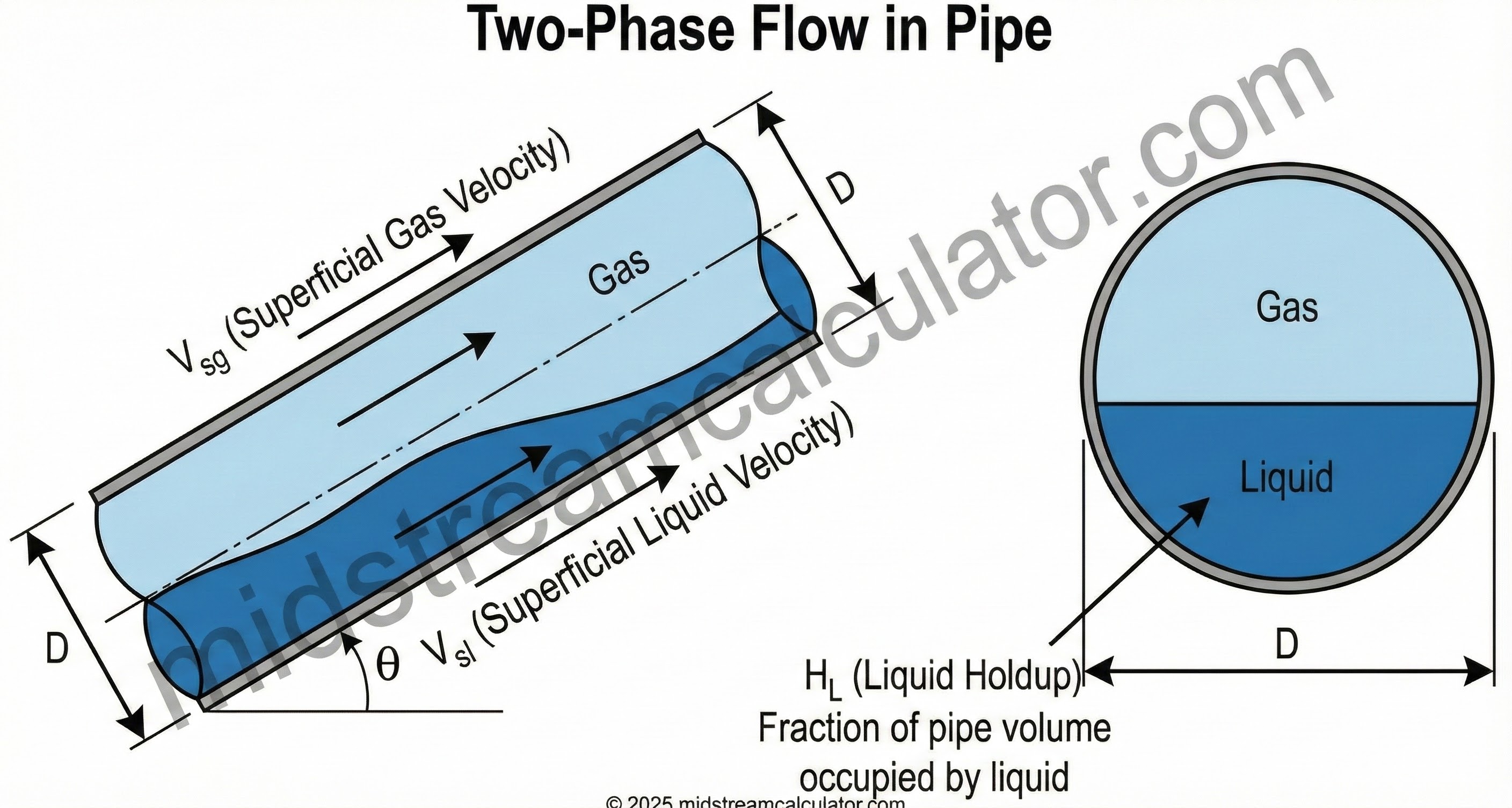

The Beggs-Brill (1973) correlation predicts pressure drop and liquid holdup for two-phase gas-liquid flow in pipes at any inclination angle. It remains widely used for gathering systems and pipelines.

Key Features

Inclination

-90° to +90°

Robust for downhill liquid draining and uphill accumulation scenarios.

Regimes

4 patterns

Segregated, intermittent, distributed, transition via λL and NFR.

Holdup

Inclination-corrected

Starts with horizontal holdup, then applies ψ(θ) factor.

Friction

2Φ multiplier

Single-phase Moody factor with S-based multiplier for slip.

Input Parameters

| Parameter | Symbol | Units |

|---|---|---|

| Superficial gas velocity | V_sg | ft/s |

| Superficial liquid velocity | V_sl | ft/s |

| Pipe inside diameter | D | ft |

| Inclination angle | θ | degrees |

| Gas density | ρ_g | lb/ft³ |

| Liquid density | ρ_l | lb/ft³ |

| Gas viscosity | μ_g | cp |

| Liquid viscosity | μ_l | cp |

| Surface tension | σ | dyne/cm |

2. Flow Regime Determination

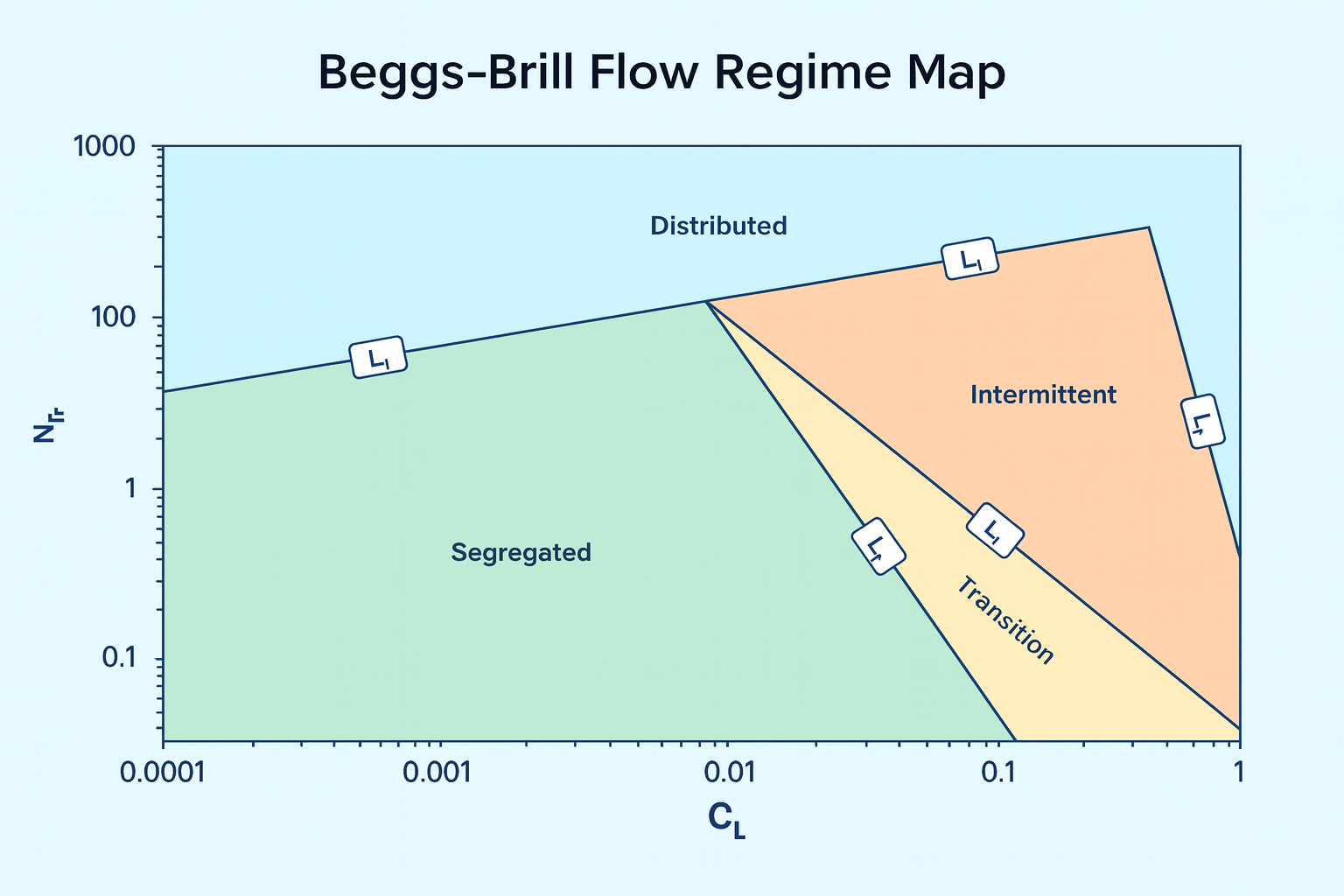

Beggs-Brill identifies four flow patterns based on dimensionless parameters:

Calculate λL and NFR. Use superficial velocities and diameter; keep units consistent.

Pick the regime. Compare NFR to L1–L4; flag if λL is outside test range.

Select coefficients. Regime drives holdup constants and inclination correction factors.

Flow Regime Map

| Regime | Condition | Description |

|---|---|---|

| Segregated | λ_L < 0.01 and N_FR < L1 or λ_L ≥ 0.01 and N_FR < L2 |

Stratified or annular; phases separated |

| Intermittent | 0.01 ≤ λ_L < 0.4 and L3 < N_FR ≤ L1 or λ_L ≥ 0.4 and L3 < N_FR ≤ L4 |

Slug or plug flow; alternating phases |

| Distributed | λ_L < 0.4 and N_FR ≥ L1 or λ_L ≥ 0.4 and N_FR > L4 |

Bubble or mist; phases well-mixed |

| Transition | L2 < N_FR < L3 | Between segregated and intermittent |

3. Liquid Holdup

Liquid holdup (H_L) is the fraction of pipe volume occupied by liquid. Beggs-Brill calculates horizontal holdup first, then corrects for inclination.

Horizontal Holdup (H_L(0))

Inclination Correction

Inclination Coefficients

| Regime | d | e | f | g |

|---|---|---|---|---|

| Segregated uphill | 0.011 | -3.768 | 3.539 | -1.614 |

| Intermittent uphill | 2.96 | 0.305 | -0.4473 | 0.0978 |

| Distributed uphill | No correction (C = 0) | |||

| All regimes downhill | 4.70 | -0.3692 | 0.1244 | -0.5056 |

Test basis

1–1.5" pipe

Expect larger error on big trunklines; compare with OLGA/field data.

Viscosity range

Light/medium

Accuracy falls for high-visc oils; watch μ_l > ~30 cp.

GVF comfort zone

20–95%

Extremes (near 0% or 100% liquid) behave closer to single-phase limits.

4. Pressure Drop Calculation

Total pressure gradient has three components:

Elevation Component

Friction Component

Example Calculation

Given: 6" pipe, 5° uphill, V_sg = 10 ft/s, V_sl = 2 ft/s, ρ_g = 3 lb/ft³, ρ_l = 50 lb/ft³

Bound with single-phase. Compare ΔP to gas-only and liquid-only to sanity check output.

Vary λL and angle. Small changes in input fraction or inclination can swing holdup significantly.

Cross-check in field. Match against pressure survey or smart pig data where available.

5. Limitations & Alternatives

Beggs-Brill Limitations

- Data basis: Developed from air-water tests in small pipes (1-1.5")

- Accuracy: ±20-30% for pressure drop, ±10-20% for holdup

- Not recommended for: High-viscosity oils, severe slugging, or very large pipes

- Three-phase: Not designed for gas-oil-water systems

Alternative Correlations

| Correlation | Best Application |

|---|---|

| OLGA / LEDAFLOW | Dynamic multiphase simulation, severe slugging |

| Mukherjee-Brill | Oil wells, deviated wells |

| Duns-Ros | Vertical gas wells |

| Hagedorn-Brown | Vertical oil wells |

| Gray | Wet gas vertical flow |

| Oliemans | Large diameter, high pressure gas-condensate |

Use confidently

Light oil / gas, modest diametersGathering lines, early feasibility, incline-aware screening.

Use with caution

High slug risk or steep slopesExpect larger holdup swings; consider dynamic modeling.

Avoid

Heavy crude or 3-phaseUse mechanistic/OLGA or field-calibrated models instead.

⚠ Validation required: Always compare correlation predictions against field data when available. Multiphase correlations can have significant errors—use multiple methods and engineering judgment.

References

- Beggs, H.D. and Brill, J.P. (1973). "A Study of Two-Phase Flow in Inclined Pipes." JPT.

- Brill, J.P. and Mukherjee, H. (1999). Multiphase Flow in Wells. SPE Monograph.

- GPSA, Section 17 (Fluid Flow)

- Shoham, O. (2006). Mechanistic Modeling of Gas-Liquid Two-Phase Flow in Pipes.

Ready to use the calculator?

→ Launch Calculator