1. NGL Recovery Fundamentals

Natural Gas Liquids (NGLs) are hydrocarbons heavier than methane that can be extracted from natural gas and sold as separate products. The decision to recover NGLs depends on the "frac spread" - the difference between NGL product value and the value of leaving those components in the gas stream.

NGL Components and Properties

| Component | Formula | NBP (°F) | HHV (BTU/SCF) | gal/MSCF | Primary Use |

|---|---|---|---|---|---|

| Ethane (C₂) | C₂H₆ | -127 | 1,769 | 26.59 | Ethylene feedstock |

| Propane (C₃) | C₃H₈ | -44 | 2,516 | 27.46 | Fuel, petrochemical |

| Isobutane (iC₄) | C₄H₁₀ | 11 | 3,252 | 32.64 | Alkylation feed |

| Normal butane (nC₄) | C₄H₁₀ | 31 | 3,262 | 31.44 | Gasoline blending |

| Natural gasoline (C₅+) | C₅H₁₂+ | 82+ | 4,008+ | 35.95 | Gasoline blending |

Source: GPSA 14th Edition Table 23-2, GPA 2145

GPM - Gallons Per Thousand SCF

GPM (Gallons Per MSCF) is the standard measure of gas "richness" - the potential liquid yield if 100% of each component were recovered. It's calculated from the gas composition and GPSA liquid yield factors.

Gas Richness Classification

| Classification | GPM Range | Typical Process | Economics |

|---|---|---|---|

| Lean Gas | < 1.5 GPM | Bypass or JT only | Marginal - verify frac spread |

| Moderate | 1.5 - 2.5 GPM | Mech refrigeration or JT | Propane recovery usually economic |

| Rich | 2.5 - 4.0 GPM | Turboexpander | Good economics for C2 recovery |

| Very Rich | > 4.0 GPM | GSP/RSV/SCORE | Excellent NGL economics |

2. Recovery Processes

Modern NGL recovery uses cryogenic processes to achieve deep separation of methane from heavier hydrocarbons. The turboexpander is the heart of most cryogenic plants, providing both cooling and work recovery.

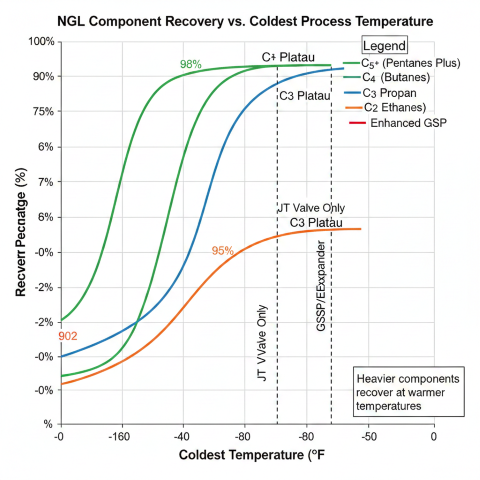

Process Comparison

| Process | Cold Temp | C₂ Recovery | C₃ Recovery | Key Feature |

|---|---|---|---|---|

| Straight Refrigeration | -20 to -40°F | 10-25% | 70-85% | Simple, low CAPEX |

| JT + Refrigeration | -60 to -80°F | 30-60% | 85-95% | No rotating equipment |

| Basic Turboexpander | -100 to -120°F | 60-80% | 92-97% | Work recovery |

| GSP (Gas Subcooled) | -130 to -150°F | 80-92% | 97-99% | Subcooled reflux |

| RSV (Recycle Split Vapor) | -140 to -160°F | 90-96% | 99%+ | Vapor recycle |

| SCORE/CRR | -150 to -170°F | 95-99% | 99%+ | Maximum C2 recovery |

GSP Process Description

The Gas Subcooled Process (GSP) is the most common high-recovery cryogenic design:

- Inlet Separation: Dehydrated gas enters at 800-1000 psig

- Cold Box: Gas-to-gas exchangers cool inlet against cold residue (-120°F approach)

- Cold Separator: Two-phase separation at -80°F to -100°F

- Subcooling: Separator liquid subcooled as demethanizer reflux

- Expansion: Remaining vapor through turboexpander (80-85% isentropic efficiency)

- Demethanizer: Trayed/packed column at 200-350 psia separates C1 from NGL

- Recompression: Residue recompressed to pipeline pressure

Key Equipment

| Equipment | Function | Key Parameter | Typical Value |

|---|---|---|---|

| Cold Box (Brazed Aluminum) | Gas-gas heat recovery | Approach temperature | 3-10°F |

| Turboexpander | Work extraction + cooling | Isentropic efficiency | 80-88% |

| Demethanizer | C1/C2+ separation | Operating pressure | 200-350 psia |

| Residue Compressor | Recompress to pipeline | Discharge pressure | 800-1200 psig |

| Reboiler | Column heat input | Bottoms temperature | 100-150°F |

CO₂ Freezing Hazard: At temperatures below -100°F, CO₂ can freeze and plug equipment. Inlet CO₂ must be limited to <2% for moderate recovery or <0.5% for deep ethane recovery. Amine treating upstream may be required.

3. Recovery Calculations

NGL recovery calculations use material balance to track each component from inlet gas through the plant. Recovery efficiency is measured as the fraction of each inlet component captured in the NGL product.

Component Recovery

Liquid Volume from Gas

Worked Example

Given: 100 MMSCFD inlet gas with 7% C₂, 4.5% C₃, 2% C₄, 0.5% C₅+

Operating at 90% C₂ recovery, 98% C₃ recovery, 99% C₄ recovery

C₂ recovered = 100 × 0.07 × 0.90 = 6.30 MMSCFD

C₃ recovered = 100 × 0.045 × 0.98 = 4.41 MMSCFD

C₄ recovered = 100 × 0.02 × 0.99 = 1.98 MMSCFD

C₅+ recovered = 100 × 0.005 × 0.999 = 0.50 MMSCFD

Step 2: Convert to liquid gallons per day

C₂ GPD = 6.30 × 1000 × 26.59 = 167,517 GPD

C₃ GPD = 4.41 × 1000 × 27.46 = 121,100 GPD

C₄ GPD = 1.98 × 1000 × 31.92 = 63,202 GPD

C₅+ GPD = 0.50 × 1000 × 35.95 = 17,975 GPD

Total NGL = 369,794 GPD = 8,805 BPD

Step 3: Calculate residue gas

Shrinkage = 6.30 + 4.41 + 1.98 + 0.50 = 13.19 MMSCFD

Residue = 100 - 13.19 = 86.81 MMSCFD

Shrinkage % = 13.19%

Residue Gas Heating Value

Shrinkage Calculation

4. Optimization Parameters

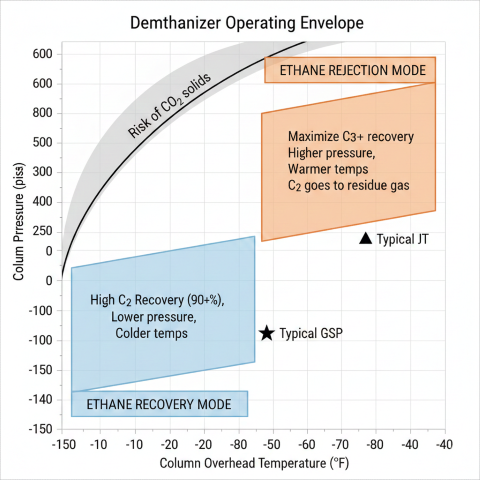

Plant operators optimize NGL recovery by adjusting operating parameters to match current feed conditions and market prices. Key variables include demethanizer pressure, expander operation, and column reflux.

Operating Variables and Effects

| Parameter | Increase Effect | Trade-off | Typical Range |

|---|---|---|---|

| Demethanizer pressure | ↓ C₂ recovery | ↓ Compression power | 200-500 psia |

| Overhead temperature | ↓ C₂ recovery | ↓ Refrigeration load | -60 to -150°F |

| Reflux ratio | ↑ C₂ recovery | ↑ Reboiler duty | 0.3-1.0 |

| Expander inlet temp | ↓ C₂ recovery | ↓ Heat exchange area | -40 to -100°F |

| Reboiler temp | ↑ C1 in bottoms | NGL spec impact | 80-150°F |

Ethane Rejection Mode

When ethane prices are low relative to natural gas, plants operate in "ethane rejection" mode to maximize residue gas BTU value:

- Increase demethanizer pressure to 400-500 psia (raises column temperature)

- Reduce reflux ratio to allow more C₂ up the column

- Reduce expander throughput or bypass to JT valve

- Result: C₂ recovery drops to 5-15%, C₃ recovery to 85-95%

Temperature Targets by Recovery Level

| Recovery Target | Coldest Temp | Demet Press | Process |

|---|---|---|---|

| C₂ rejection (C₃+ only) | -40 to -60°F | 400-600 psia | JT or warm expander |

| Partial C₂ (60-75%) | -80 to -110°F | 300-400 psia | Turboexpander |

| High C₂ (85-92%) | -120 to -140°F | 250-350 psia | GSP |

| Deep C₂ (>95%) | -150 to -170°F | 200-280 psia | RSV/SCORE |

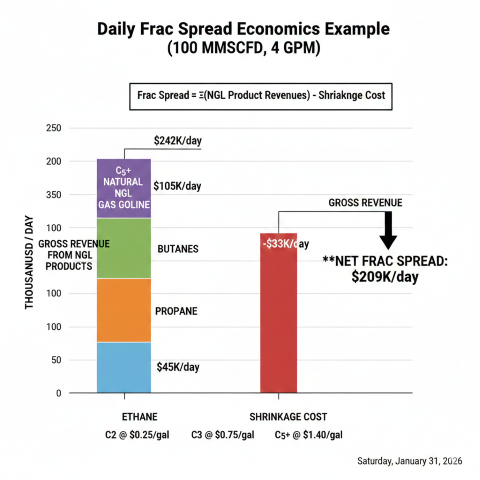

5. Economic Considerations

NGL recovery economics are driven by the "frac spread" - the value of extracted NGL products minus the value of the gas shrinkage left behind. Positive frac spread means extraction adds value; negative spread suggests rejection.

Frac Spread Calculation

NGL Product Pricing

| Product | Spec | Pricing Hub | Typical Range |

|---|---|---|---|

| Ethane | EP Grade (95%+) | Mont Belvieu | $0.15-0.40/gal |

| Propane | HD-5 | Mont Belvieu, Conway | $0.60-1.20/gal |

| Normal Butane | Commercial | Mont Belvieu | $0.80-1.40/gal |

| Isobutane | Commercial | Mont Belvieu | $0.90-1.50/gal |

| Natural Gasoline | Y-Grade | NYMEX-related | $1.20-2.00/gal |

Operating Cost Factors

- Compression power: Residue recompression is 40-60% of operating cost

- Fuel gas: Reboiler heat, regeneration, building heat

- Refrigeration: External propane or mixed refrigerant systems

- Treating chemicals: Amine, glycol makeup

- Maintenance: Rotating equipment, heat exchangers, instrumentation

Rule of Thumb: Total plant operating cost is typically $0.08-0.20 per gallon of NGL produced, depending on plant size, age, and complexity. This translates to ~$3-8 per barrel of NGL.

References

- GPSA, Section 16 (Hydrocarbon Recovery)

- GPA Standard 2145 - Table of Physical Constants for Hydrocarbons

- Campbell, J.M. "Gas Conditioning and Processing", Volume 2

- Arnold & Stewart, "Surface Production Operations", Volume 2

Ready to use the calculator?

→ Launch Calculator