1. Heat Transfer Fundamentals

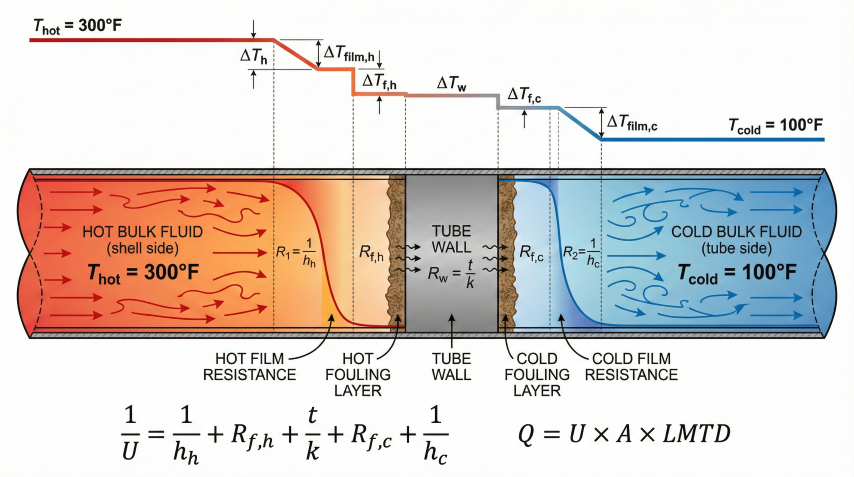

Heat exchangers transfer thermal energy between fluids at different temperatures. The heat transfer rate depends on three mechanisms acting in series:

Conduction

Through walls

Heat flows through tube walls separating hot and cold fluids.

Convection

Film coefficients

Hot-side hh and cold-side hc control fluid-to-wall transfer.

Fouling

Resistance buildup

Deposits reduce U over time; design includes fouling margins per TEMA.

Fundamental Heat Transfer Equation

Overall Heat Transfer Coefficient (U)

U combines all resistances in series—hot-side film, tube wall, cold-side film, and fouling:

Typical Overall U Values

| Service | U Clean | U Design |

|---|---|---|

| Water to water | 200–250 | 150–200 |

| Water to light oil | 80–120 | 60–90 |

| Light oil to light oil | 60–90 | 40–60 |

| Heavy oil to heavy oil | 30–50 | 20–35 |

| Gas to gas (no fins) | 10–30 | 8–25 |

| Condensing steam to water | 400–600 | 300–500 |

Units: BTU/hr·ft²·°F. Design U includes fouling allowance per TEMA.

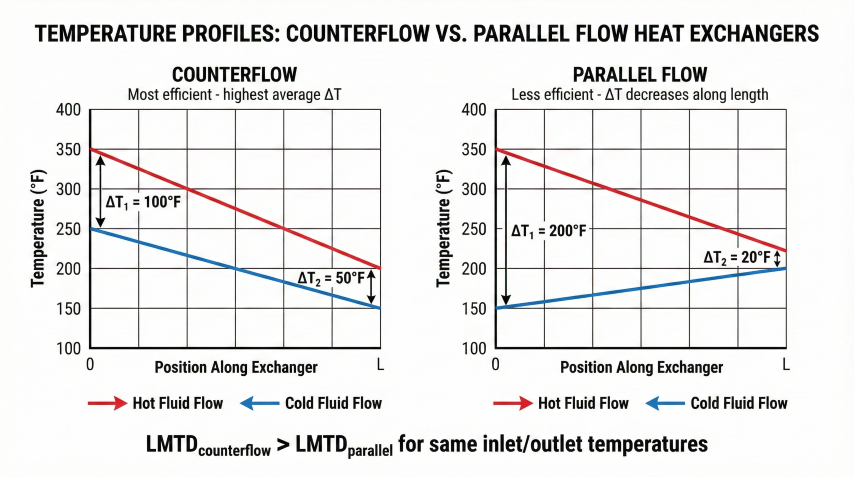

2. Log Mean Temperature Difference (LMTD)

LMTD represents the effective temperature driving force when terminal temperatures vary along the exchanger length. It accounts for the logarithmic temperature profile in heat exchangers.

Counterflow Configuration

Most efficient arrangement—hot fluid enters where cold fluid exits, maximizing ΔT at both ends.

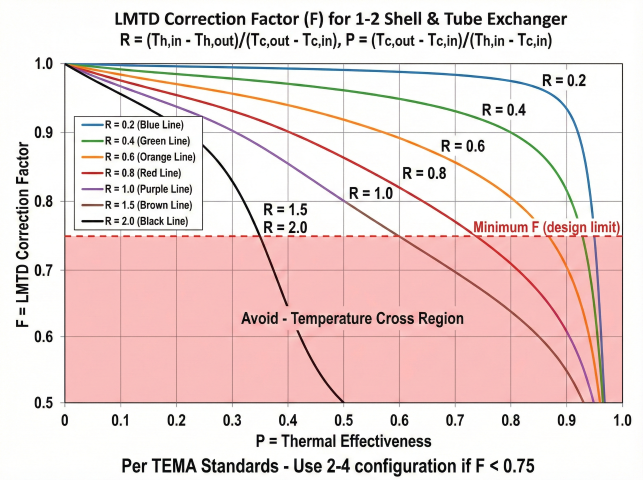

LMTD Correction Factor (F)

For shell-and-tube exchangers with multiple passes, actual mean ΔT is lower than pure counterflow. The F factor corrects for this:

F Factor Guidelines

| Configuration | F Range | Comments |

|---|---|---|

| True counterflow | 1.0 | Maximum effectiveness |

| 1-2 shell & tube | 0.75–0.95 | Most common; avoid F < 0.75 |

| 2-4 shell & tube | 0.85–0.98 | Higher F but more expensive |

| Crossflow (air-cooled) | 0.70–0.90 | Lower due to flow pattern |

Example Calculation

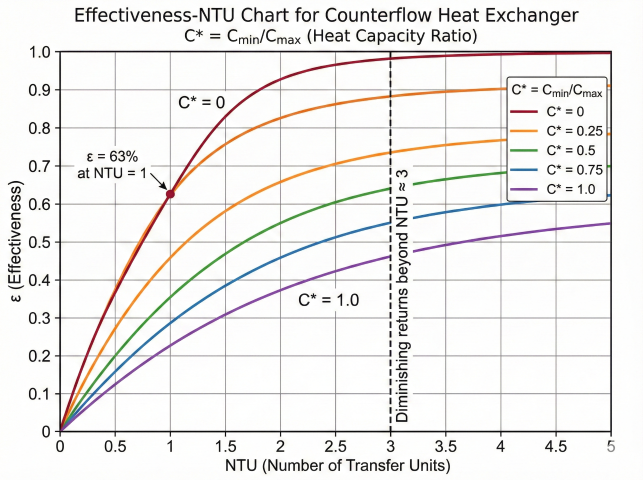

3. Effectiveness-NTU Method

Alternative to LMTD when outlet temperatures are unknown. Essential for rating existing exchangers or iterative design optimization.

Thermal Effectiveness (ε)

Number of Transfer Units (NTU)

Heat Capacity Ratio (C*)

Effectiveness Correlations

Counterflow

Parallel Flow

Phase Change (C* = 0)

When to Use Each Method

| Situation | Method | Reason |

|---|---|---|

| All 4 temperatures known | LMTD | Simpler calculation |

| Outlet temps unknown | ε-NTU | Direct solution |

| Rating existing exchanger | ε-NTU | Given area, find outlets |

| Phase change process | ε-NTU | C* = 0 simplifies equations |

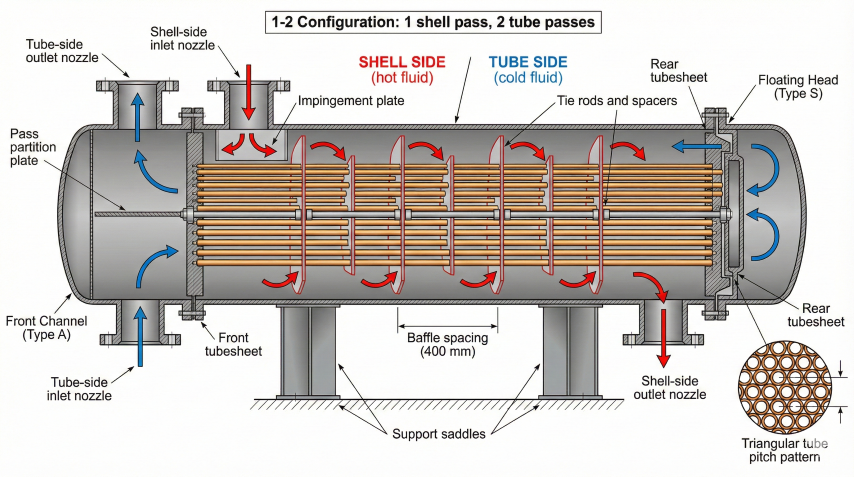

4. Shell-and-Tube Design

Shell-and-tube exchangers are the workhorse of process industries—robust, repairable, and scalable to very large duties.

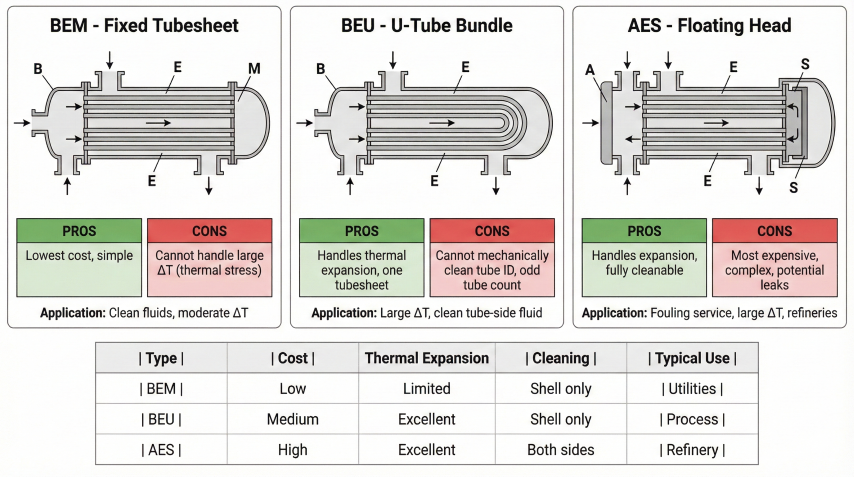

TEMA Nomenclature

Exchangers are designated by three letters: Front Head - Shell Type - Rear Head

| Position | Code | Description |

|---|---|---|

| Front Head | A | Channel with removable cover |

| B | Bonnet (integral cover) | |

| N | Channel with removable cover & tubesheet | |

| Shell Type | E | One-pass shell (most common) |

| F | Two-pass shell (longitudinal baffle) | |

| J | Divided flow | |

| X | Crossflow | |

| Rear Head | L, M, N | Fixed tubesheet types |

| S, T | Floating head types | |

| U | U-tube bundle |

Example: AES = Channel with removable cover, one-pass shell, floating head (most common for refinery service).

Key Design Parameters

| Parameter | Typical Values | Notes |

|---|---|---|

| Tube OD | ¾" or 1" | ¾" most common; 1" for fouling |

| Tube wall | BWG 12, 14, 16 | Thicker for high P or corrosion |

| Tube length | 8, 12, 16, 20 ft | Longer = more area, harder to clean |

| Pitch | 1.25 × OD | Triangular for high h; square for cleaning |

| Baffle spacing | 0.2–1.0 × shell ID | Closer = higher h, higher ΔP |

| Baffle cut | 20–35% of shell ID | 25% typical; affects flow pattern |

Fluid Allocation Guidelines

Tube Side

Place here:

Corrosive fluids (alloy tubes cheaper), high-pressure fluids, fouling fluids (easier to clean), cooling water.

Shell Side

Place here:

Low-pressure fluids, viscous fluids (need turbulence), condensing vapors, fluids needing large flow area.

TEMA Mechanical Design Classes

| Class | Application | Features |

|---|---|---|

| R | Refinery / Severe | Heaviest construction; high T/P; full ASME VIII Div 1 |

| C | Commercial / Moderate | General process; lower cost than R |

| B | Chemical / Light | Least severe; lowest cost; often fixed tubesheet |

5. Exchanger Types & Selection

Shell-and-Tube

Advantages

Proven workhorse

Handles high P/T, large duties, mechanically cleanable, repairable.

Disadvantages

Large footprint

Bulky, heavy, higher cost per ft² than plate types.

Best for

Refinery / gas plants

High P (>300 psi), high T (>400°F), large Q (>10 MMBtu/hr).

Plate Heat Exchangers

Advantages

Compact, high U

U = 800–2000; 3–5× more compact; easy to expand capacity.

Disadvantages

Limited P/T, fouling

Max ~300 psi, 350°F; gaskets; narrow channels foul easily.

Best for

Clean liquid services

HVAC, food/pharma, moderate P/T, tight space.

Air-Cooled Exchangers (Fin-Fan)

Advantages

No cooling water

Eliminates cooling tower, water treatment, blowdown.

Disadvantages

Weather dependent

Cannot cool below ambient + 15–20°F; large footprint.

Best for

Remote / arid sites

No water available; compressor aftercoolers; overhead condensers.

Selection Criteria Summary

| Application | Recommended Type | Reason |

|---|---|---|

| Gas-gas | Shell-tube (finned) or plate-fin | Low h requires extended surface |

| Gas-liquid | Shell-tube or air-cooled | Shell-tube for high P |

| Liquid-liquid (clean) | Plate or shell-tube | Plate if P/T permit |

| Liquid-liquid (fouling) | Shell-tube (square pitch) | Mechanical cleaning access |

| High pressure (>500 psi) | Shell-tube or double-pipe | Thick-wall tubes cheaper than plates |

| Phase change (condensing) | Shell-tube (vapor shell side) | Large flow area; gravity drainage |

| Remote / no water | Air-cooled | Eliminates water infrastructure |

Fouling Mitigation

- Design velocity: Tube-side ≥ 3 ft/s for liquids to minimize deposits

- Square pitch: Allows mechanical cleaning between tubes

- Removable bundle: TEMA types with pullable bundles (AES, BEU)

- Oversurface: Add 10–20% excess area to maintain duty as fouling builds

Ready to use the calculator?

→ Launch Calculator