Service Conditions

Gas Properties

Design Parameters

📚 Learn the Theory

Understand coalescing filter design, element sizing, two-stage separation, and efficiency calculations

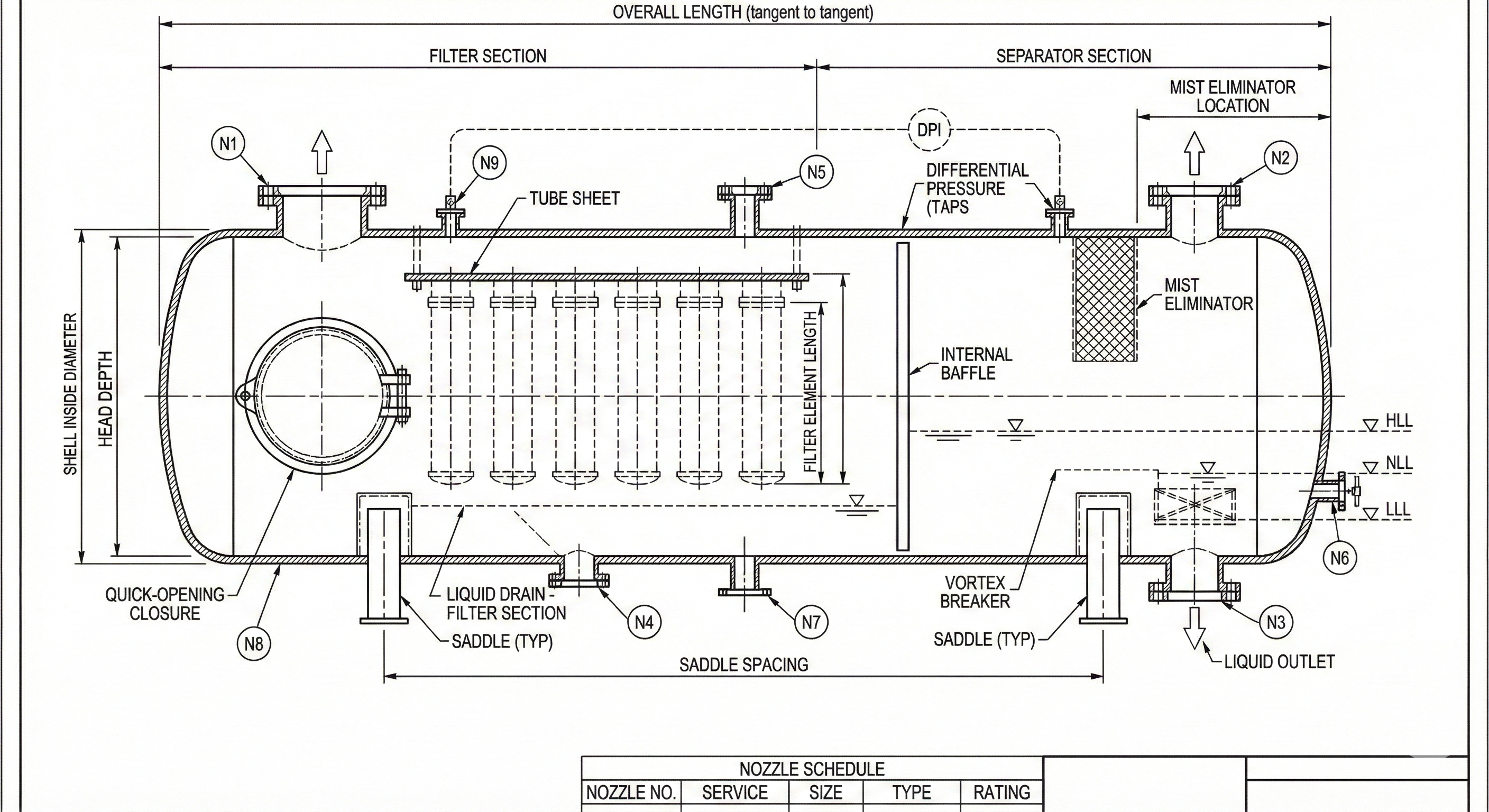

Filter Separator Design

Element Capacity:

Face velocity typically 40-80 ft/min for coalescing elements

Pressure Drop (Clean):

Typical Element Capacities (ACFM/element):

• 6" × 36" Fiberglass: 80-120 ACFM

• 6" × 48" Fiberglass: 100-150 ACFM

• Pleated cartridge: 150-300 ACFM

Service Requirements:

• Fuel gas: ≤0.1 gal/MMSCF outlet

• Instrument gas: ≤0.01 gal/MMSCF outlet

• Custody transfer: Per contract spec