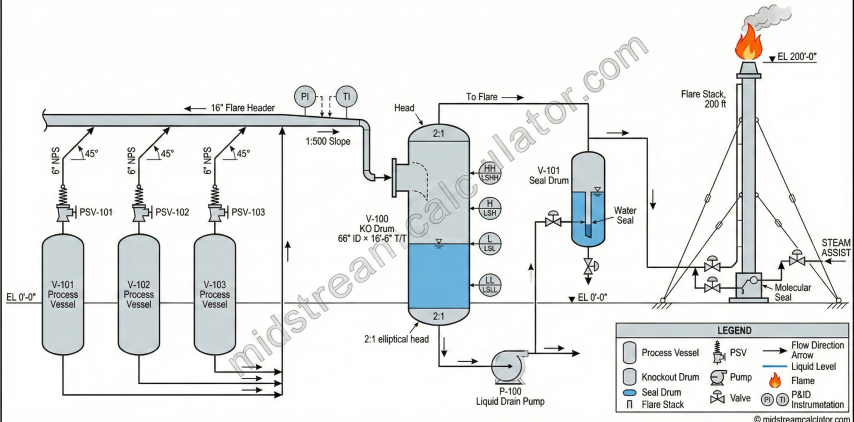

1. System Overview

Flare disposal systems safely collect, transport, and combust relief discharges from pressure safety valves (PSVs), blowdown valves, and emergency depressuring systems. The system must handle transient high-flow events while maintaining acceptable backpressure on relief devices.

Flare header

Collect & transport

Routes relief gases from multiple sources to the flare stack or ground flare.

Knockout drum

Liquid separation

Removes entrained liquids before combustion to prevent liquid carryover to flare tip.

Liquid seal drum

Flashback prevention

Water seal prevents flame propagation back into the header system.

Flare stack/tip

Combustion

Elevated or ground-level combustion with proper radiation protection.

Key Design Criteria

- Backpressure limit: Total backpressure at PSV outlet must not exceed allowable (typically 10% of set pressure for conventional valves)

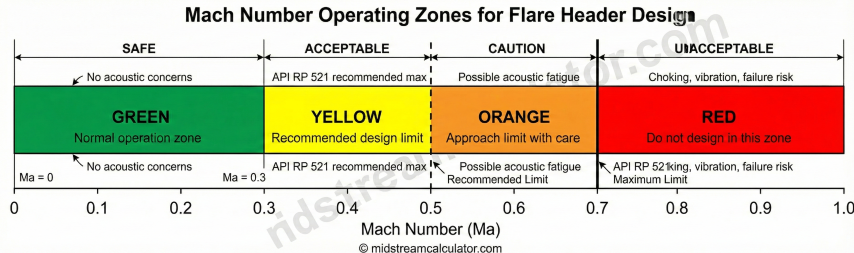

- Mach number: Velocity must remain below sonic to prevent choking and acoustic fatigue

- Liquid separation: KO drum must capture entrained liquids to protect flare tip and prevent liquid rainout

- Seal integrity: Liquid seal must prevent flashback under all operating conditions

Typical Relief Scenarios

| Scenario | Duration | Flow Character | Design Consideration |

|---|---|---|---|

| Fire case | Extended (hours) | Steady, vapor | Simultaneous relief from fire-exposed vessels |

| Power failure | Minutes | Peak then decay | Loss of cooling/compression across plant |

| Blocked outlet | Minutes | Steady, single source | Usually single PSV, check header routing |

| Emergency depressuring | 15-20 min | High initial, decaying | Largest single relief load typically |

| Tube rupture | Minutes | Steady, two-phase | High liquid fraction possible |

2. Flare Header Design

Flare header sizing ensures adequate flow capacity while limiting velocity to prevent acoustic vibration, erosion, and excessive pressure drop.

Pressure Drop Calculation (Darcy-Weisbach)

Friction Factor (Churchill Equation)

Mach Number Calculation

Header Sizing Criteria

| Parameter | Limit | Basis |

|---|---|---|

| Mach number | ≤ 0.5 (recommended) / ≤ 0.7 (max) | API RP 521 acoustic fatigue prevention |

| Gas velocity | Typically 100-300 ft/s | Function of Mach and sonic velocity |

| Pressure drop | < 10% of PSV backpressure allowable | PSV capacity depends on backpressure |

| Erosion velocity | V × √ρ < 100 | API RP 14E erosional velocity |

Two-Phase Flow Considerations

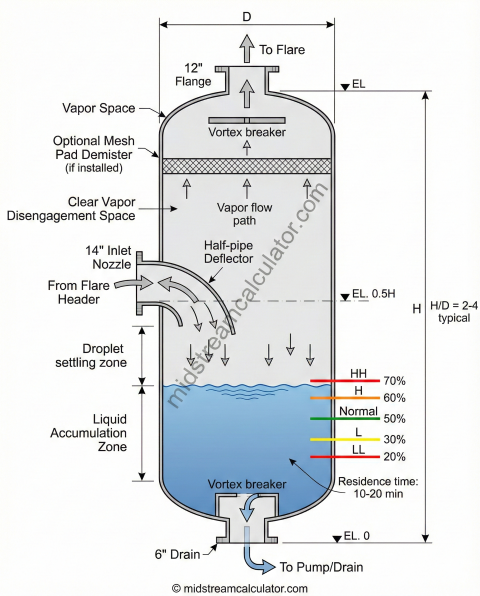

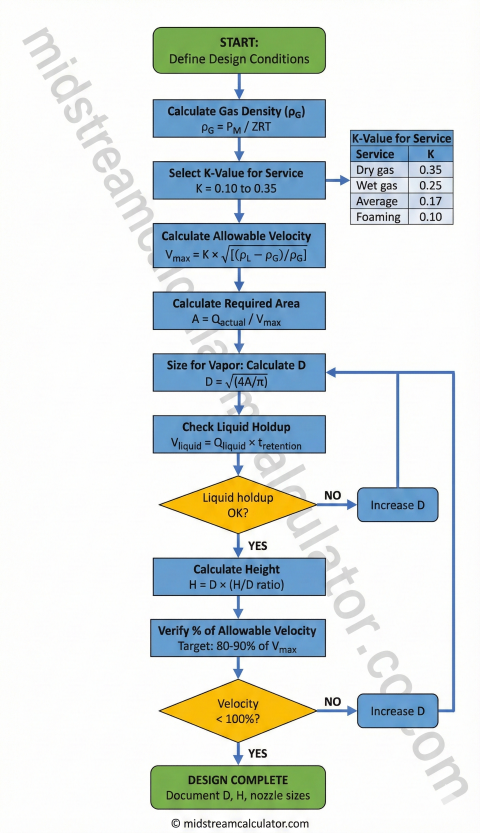

3. Knockout Drum Sizing

Knockout drums (KO drums) separate entrained liquid droplets from the vapor stream before the flare tip. Proper sizing prevents liquid carryover (burning liquid rain) and ensures adequate liquid storage capacity.

Souders-Brown Vapor Velocity

Drum Diameter Sizing

Liquid Holdup and Height

K-Value Selection Guide

| Service | K (ft/s) | Characteristics |

|---|---|---|

| Dry gas (no liquid) | 0.35 | No liquid expected; emergency vent only |

| Wet gas (some liquid) | 0.25 | Light liquid carryover; methane/ethane |

| Average service | 0.17 | Typical oil/gas; condensate + gas |

| Dirty/foaming | 0.125 | High liquid; surfactants; crude oil |

| Glycol/amine | 0.10 | Highly foaming; chemical contamination |

4. Design Examples

Example 1: Flare Header Pressure Drop

Example 2: Knockout Drum Sizing

5. Best Practices

Header Design

- Sloping: Install headers with 1:500 minimum slope toward KO drum to drain liquids

- Pockets: Avoid low points that trap liquid; install drip legs with level switches where unavoidable

- Lateral connections: Connect subheaders to main header at 45° in flow direction

- Velocity balance: Size laterals so velocity increase at junction doesn't exceed Mach limit

- Thermal expansion: Provide adequate flexibility for temperature excursions during relief events

Knockout Drum Design

- Inlet device: Use half-pipe, impingement plate, or tangential entry to reduce inlet velocity

- Vapor outlet: Locate in top head with vortex breaker; avoid direct path from inlet

- Liquid outlet: Provide vortex breaker; size for twice normal liquid rate

- Level control: Install HH/H/L/LL level switches; HH triggers automatic pump start

- Drainage: Connect to closed drain system; do not drain to atmosphere

Common Design Errors

| Error | Consequence | Prevention |

|---|---|---|

| Undersized header (Ma > 0.7) | Choking, acoustic vibration, high backpressure | Size for Ma ≤ 0.5 at maximum flow |

| Wrong K-value selection | Liquid carryover to flare tip | Use conservative K for uncertain service |

| Inadequate liquid holdup | Drum overflow, loss of seal | Size for 2× expected liquid rate |

| Header low points | Liquid accumulation, slugging, seal loss | Maintain continuous slope; add drip legs |

| Ignoring two-phase flow | Actual ΔP 3-10× calculated | Apply Lockhart-Martinelli for liquid > 5% |

Ready to use the calculator?

→ Launch Calculator