1. Fire Case Principles

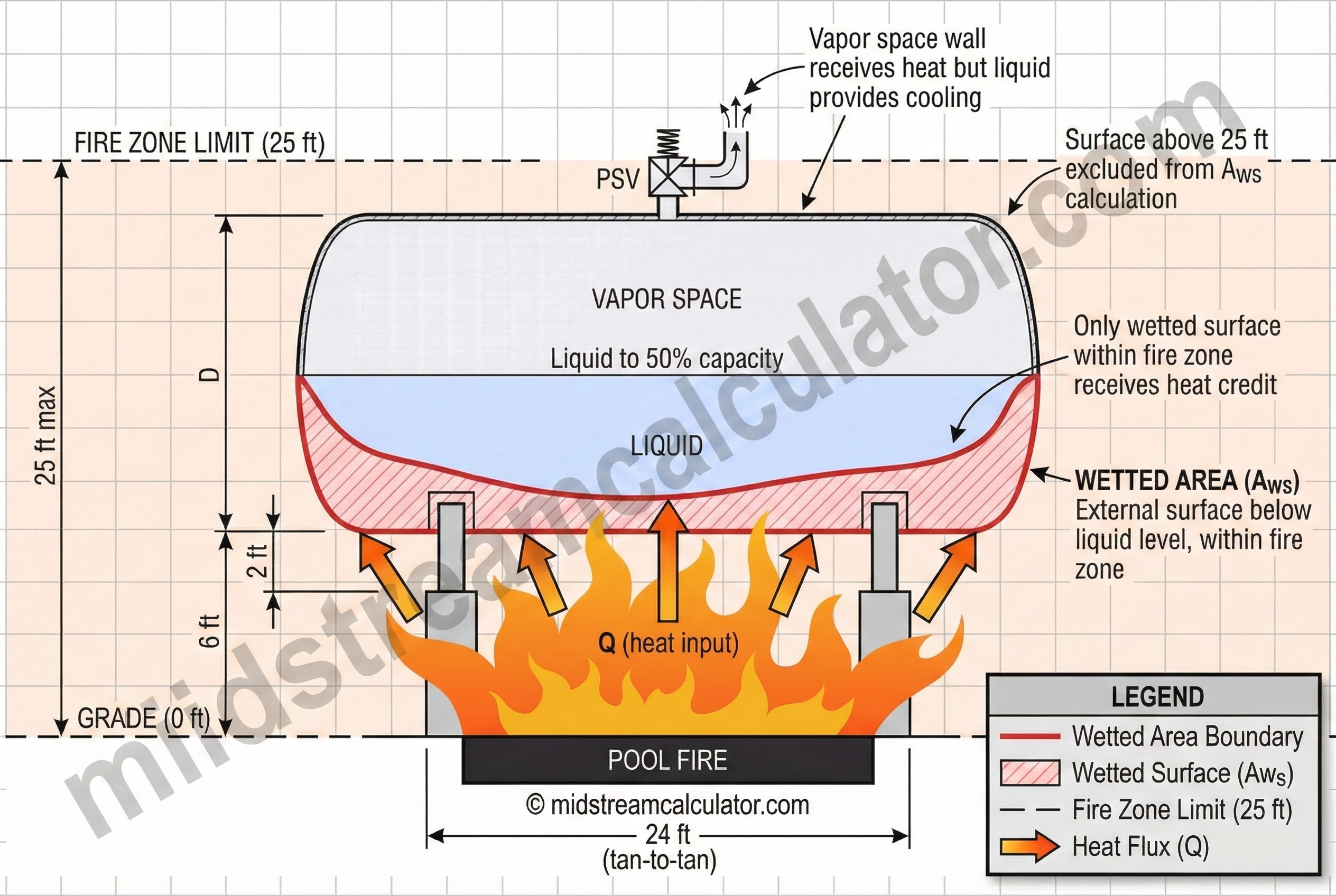

Fire exposure can cause rapid pressure rise in vessels containing liquids that vaporize when heated. Relief devices must handle the vapor generation rate to prevent vessel rupture.

Fire Case Scenario

Heat source

Pool fire

Assume spill-fed fire around vessel; flame height ~25–30 ft.

Exposure time

Until inventory gone

No credit for firefighting unless fully justified.

Relief driver

Vapor generation

Boil-off from wetted area drives relief load; liquid-only cases are rare.

Spacing

25 ft zone

Only area ≤25 ft above grade is considered fire-exposed.

Governing Standards

| Standard | Scope |

|---|---|

| API 521 | Pressure-relieving and depressuring systems (fire case methodology) |

| API 520 Part I | Relief device sizing equations |

| NFPA 30 | Flammable liquids storage |

| 29 CFR 1910.106 | OSHA flammable liquid requirements |

2. Wetted Area Calculation

Wetted area is the vessel surface in contact with liquid that is also within the fire exposure zone (typically 25 ft above grade).

Horizontal Vessel

Vertical Vessel

Sphere

3. Heat Input Equations

API 521 provides equations for heat absorption based on wetted area and drainage/firefighting provisions.

Heat Input Equations

Environmental Factor (F)

| Condition | F Factor | Notes |

|---|---|---|

| Bare vessel (no insulation) | 1.0 | Default assumption |

| Water deluge (≥0.25 gpm/ft²) | 0.5 | Reliable water supply required |

| Depressuring + drainage | 0.3 | Auto-blowdown to safe pressure |

| Approved fireproof insulation | 0.3 | Must withstand 1660°F for 2 hrs |

| Insulation (conductance 4 BTU/hr·ft²·°F) | 0.3 | Minimum credit for insulation |

| Insulation (conductance 2 BTU/hr·ft²·°F) | 0.15 | Better insulation performance |

| Insulation (conductance 1 BTU/hr·ft²·°F) | 0.075 | High-performance insulation |

| Earth-covered storage | 0.03 | Underground or mounded tanks |

Reference: API 521 Table 5 — Environment factors for fire exposure calculations.

⚠ Insulation requirements: To claim F < 1.0, insulation must be fireproof (calcium silicate, mineral wool with stainless steel jacket). Standard weatherproofing does not qualify.

Set exposure assumptions. Define drainage/spacing and insulation to pick the correct C and F factors.

Compute Q. Use the API 521 equation with wetted area capped at 25 ft.

Document credit. If claiming F < 1.0 or water spray, capture justification in the relief summary.

4. Relief Load Calculation

The relief load equals the vapor generation rate from heat input divided by latent heat of vaporization.

Latent Heat Values

| Fluid | Condition | λ (BTU/lb) |

|---|---|---|

| Water | 100 psig (338°F) | 881 |

| Water | 250 psig (406°F) | 820 |

| Propane | 100 psig (saturation) | 150 |

| Propane | 250 psig (saturation) | 110 |

| Butane | 100 psig (saturation) | 130 |

| Pentane | 50 psig (saturation) | 140 |

| Crude oil (light) | Atmospheric | 100–120 |

Example Calculation

Given: Horizontal propane vessel, 10 ft diameter × 40 ft long, 80% full, bare vessel, adequate drainage

Step 1: Wetted area

Step 2: Heat input

Step 3: Relief load

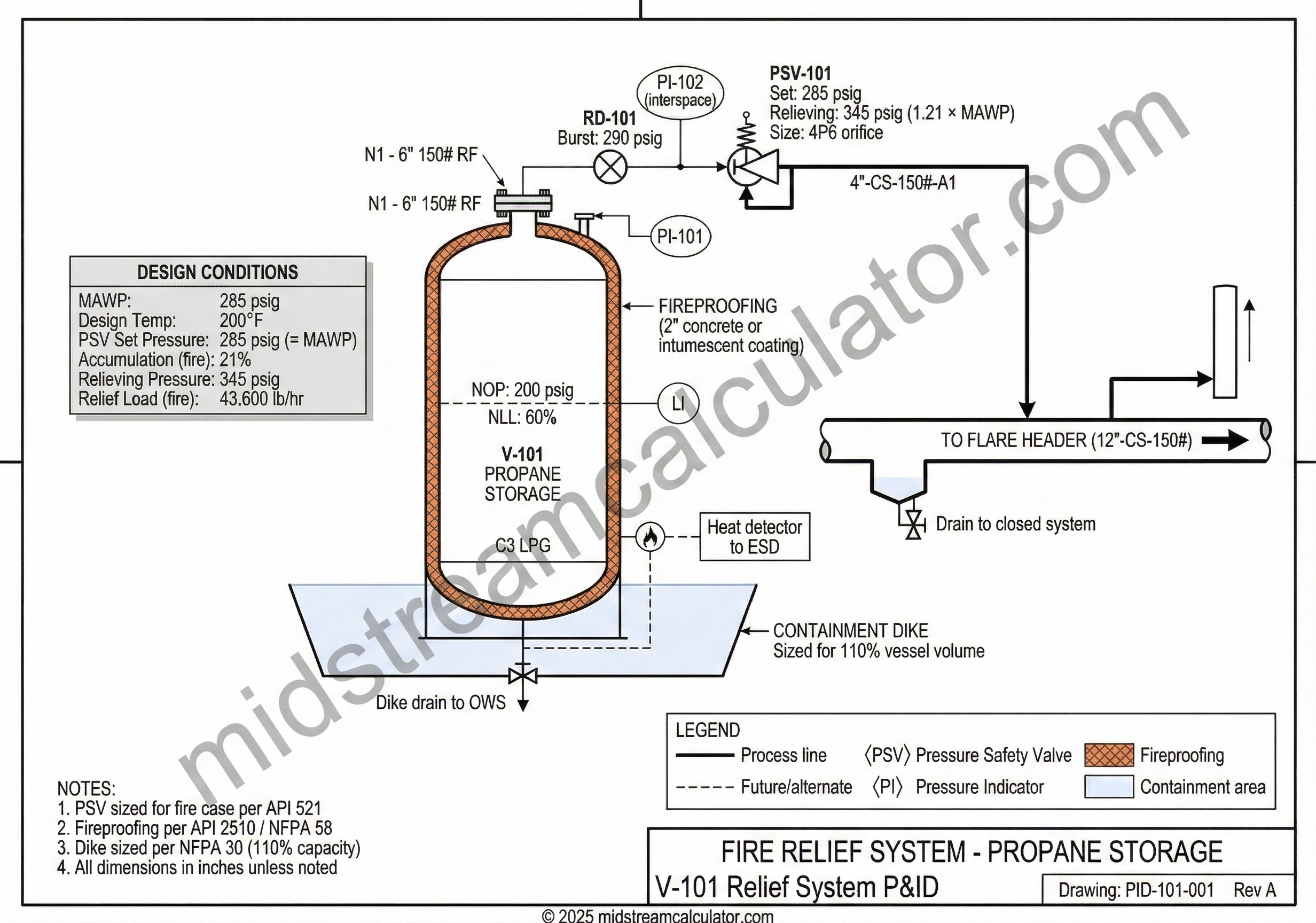

5. Design Considerations

Relief Device Sizing

Use API 520 gas sizing equation with fire case relief load:

Relief Pressure

| Parameter | Fire Case Allowance |

|---|---|

| Set pressure | ≤ MAWP |

| Accumulation (fire only) | 21% above MAWP |

| Relieving pressure | 1.21 × MAWP |

💡 Design Margin Assurance

Relieving pressure of 121% MAWP is permitted for fire cases per API 520 Part I, Table 6. Vessel integrity is assured since ASME Section VIII requires hydrostatic testing to 150% MAWP (1.5 × design pressure), providing adequate margin above fire-case relieving conditions.

References:

• API 520 Part I, 10th Ed., Table 6 – Pressure Limits for Pressure-Relief Devices

• ASME BPVC Section VIII, Div. 1, UG-99 – Hydrostatic Testing Requirements

Alternative Protection Methods

- Depressuring: Automatic blowdown to reduce pressure below failure threshold (API 521 Section 5.15)

- Water spray: Deluge system reduces heat input (requires reliable water supply)

- Fireproofing: Concrete or intumescent coating extends survival time

- Remote location: Adequate spacing reduces fire exposure probability

References

- API 521 – Pressure-Relieving and Depressuring Systems, 7th Edition

- API 520 Part I – Sizing, Selection, and Installation of PRDs

- API 2000 – Venting Atmospheric and Low-Pressure Storage Tanks

- NFPA 30 – Flammable and Combustible Liquids Code

Ready to use the calculator?

→ Launch Calculator