1. Overview

Accurate volume calculations ensure correct material ordering and prevent costly mid-pour shortages. Concrete is ordered in cubic yards (US) or cubic meters (metric).

Equipment pads

Compressors, pumps

Reinforced pads for dynamic loads.

Tank foundations

Ring walls, full pads

Support storage tanks.

Pipe supports

Piers, pedestals

Drilled shafts for pipelines.

Building slabs

Control rooms

Floor slabs for structures.

Units and Conversions

Waste Factors

| Application | Factor | Reason |

|---|---|---|

| Formed walls | +5–10% | Precise forms |

| Slab on grade | +10–15% | Subgrade variation |

| Drilled piers | +15–20% | Over-drilling |

| Complex shapes | +15–20% | Irregular geometry |

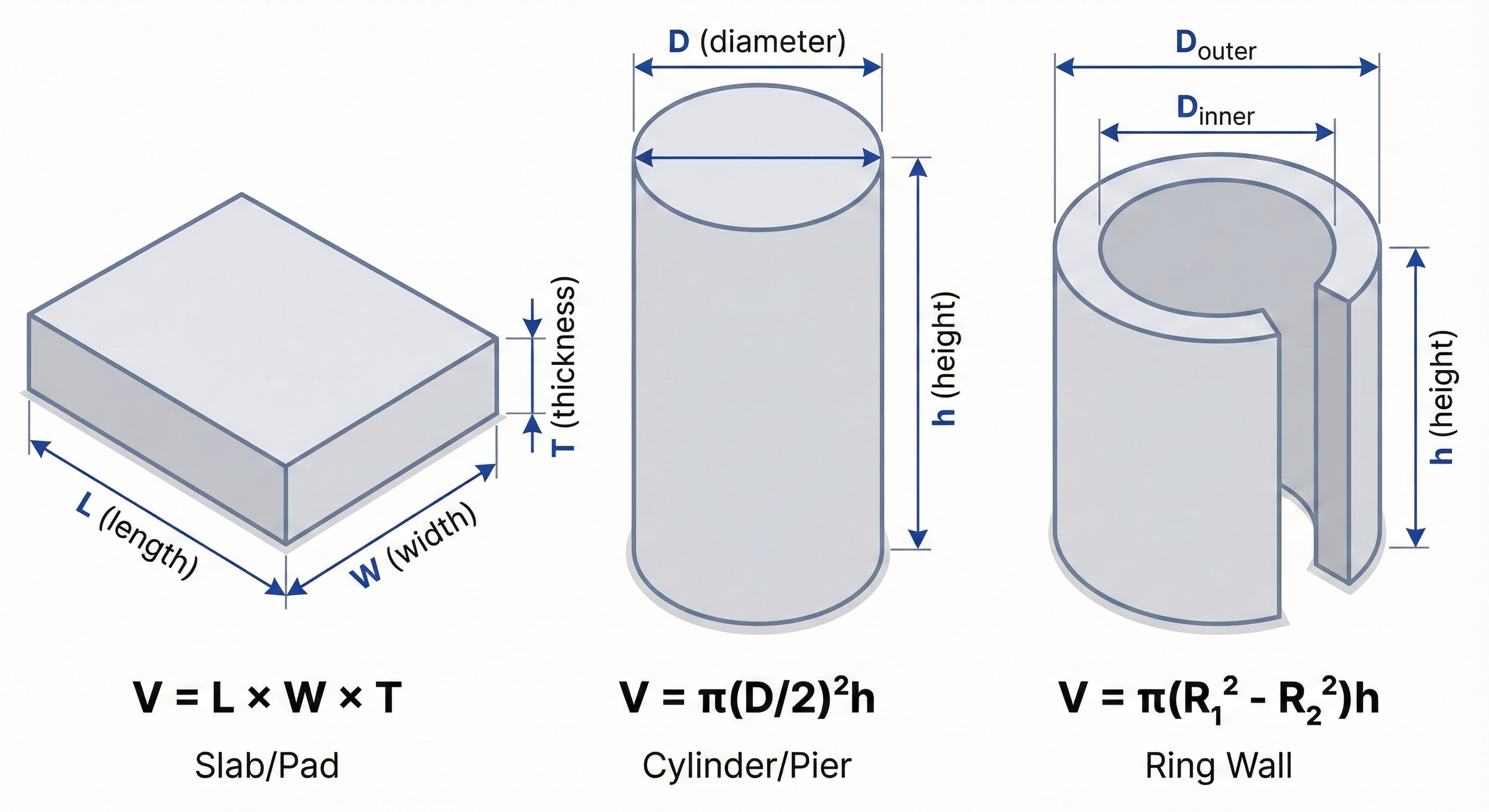

2. Volume Formulas

Break complex shapes into simple geometries, calculate each, then sum. Always convert to cubic yards for ordering.

Rectangular Slab

Cylinder (Pier)

Ring Wall (Hollow Cylinder)

Footing with Wall

Formula Summary

| Shape | Formula |

|---|---|

| Rectangle | V = L × W × T |

| Cylinder | V = π r² h |

| Ring wall | V = π (R₁² − R₂²) h |

| Triangle prism | V = ½ b h L |

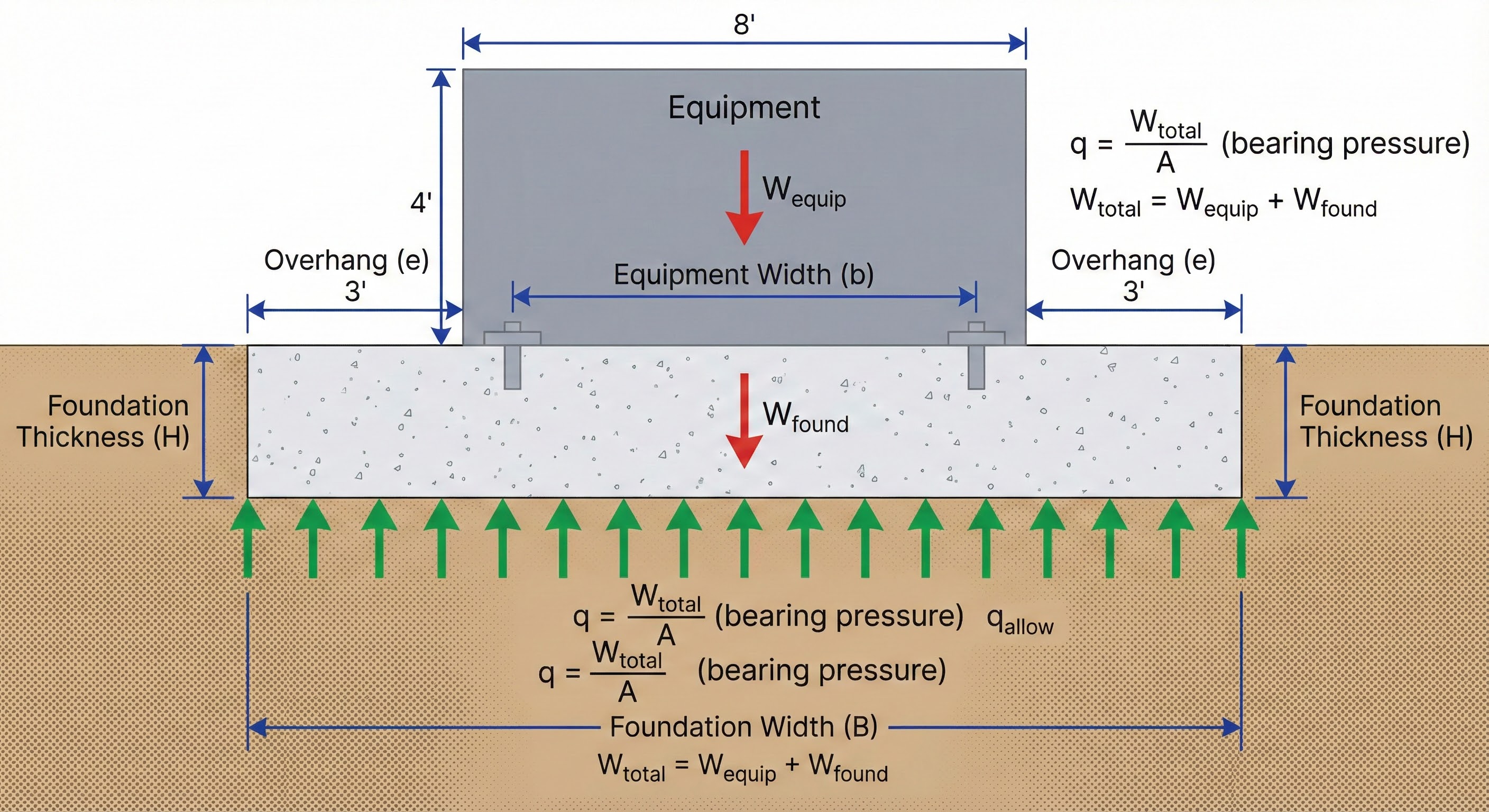

3. Equipment Foundations

Foundation size depends on equipment weight, soil capacity, and vibration requirements.

Sizing Criteria

Design Example

Tank Foundations

| Tank Size | Foundation Type | Concrete |

|---|---|---|

| < 20 ft dia | Full pad, 6–12 in | 1–5 yd³ |

| 20–50 ft dia | Ring wall + fill | 5–20 yd³ |

| > 50 ft dia | Ring wall | 20–100 yd³ |

Pipe Support Piers

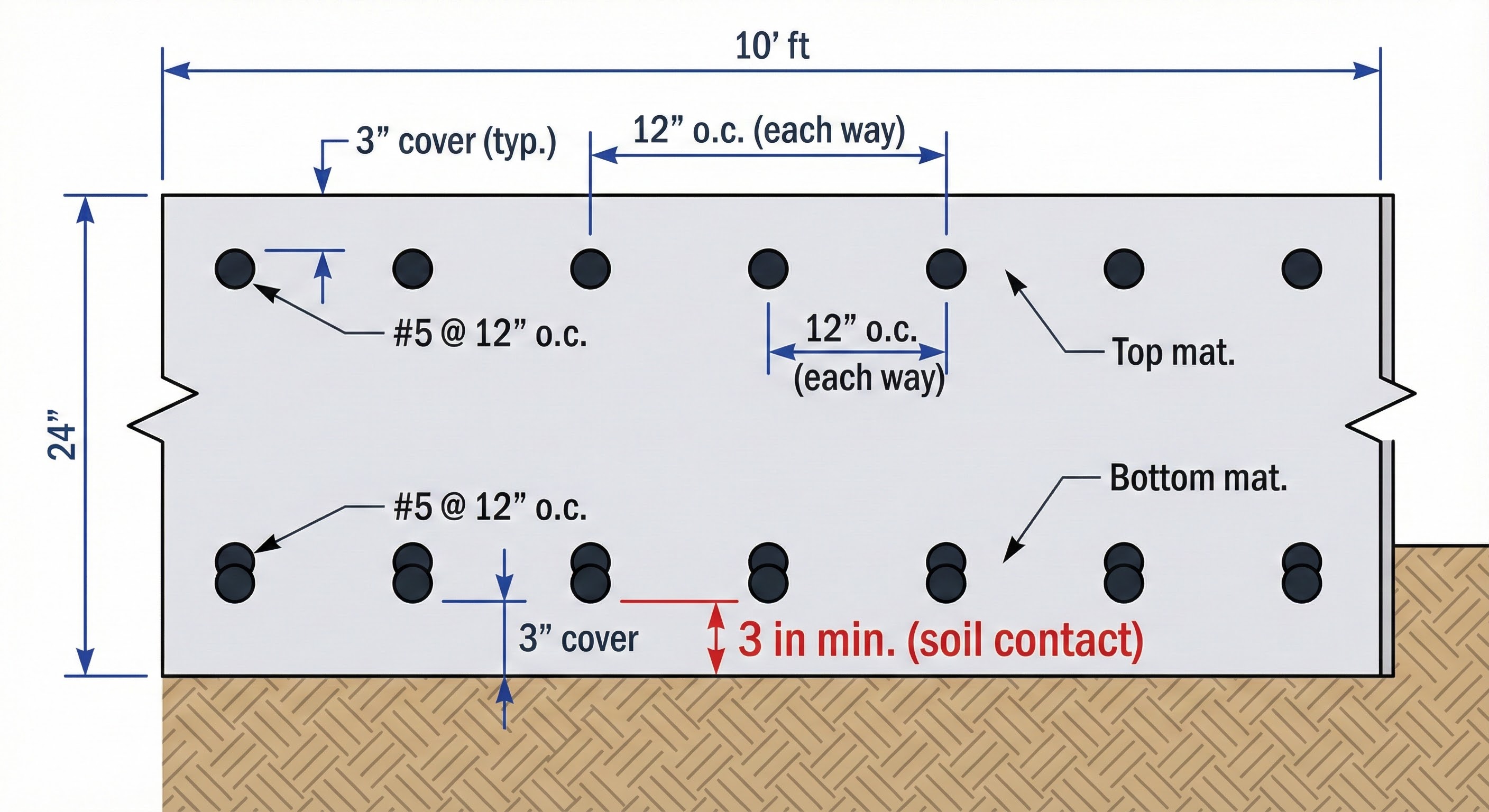

4. Reinforcement

Rebar provides tensile strength and crack control. Quantities estimated from steel ratios or bar schedules.

Reinforcement Ratios

Rebar Sizes

| Bar | Dia (in) | Weight (lb/ft) | Area (in²) |

|---|---|---|---|

| #3 | 0.375 | 0.376 | 0.11 |

| #4 | 0.500 | 0.668 | 0.20 |

| #5 | 0.625 | 1.043 | 0.31 |

| #6 | 0.750 | 1.502 | 0.44 |

| #7 | 0.875 | 2.044 | 0.60 |

| #8 | 1.000 | 2.670 | 0.79 |

Concrete Mix Specifications

| Strength | Application |

|---|---|

| 3,000 psi | Light-duty, non-structural |

| 4,000 psi | Standard foundations |

| 5,000 psi | Heavy equipment, high loads |

| 6,000+ psi | Special applications |

5. Field Practices

Pre-Pour Checklist

- Verify formwork dimensions match drawings

- Check rebar size, spacing, cover, and lap splices

- Confirm anchor bolt locations and projections

- Ensure subgrade is compacted and not frozen

- Coordinate truck arrival schedule

Temperature Requirements

| Condition | Requirement |

|---|---|

| Cold weather (< 40°F) | Heat materials, insulate, maintain 50°F min for 3–7 days |

| Hot weather (> 85°F) | Cool mix, add retarder, max 90°F at placement |

| Normal | Begin curing immediately, maintain moist 7 days |

Common Issues

| Problem | Cause | Prevention |

|---|---|---|

| Cracking | Shrinkage, poor curing | Control joints, proper curing |

| Honeycomb | Poor vibration | Proper consolidation |

| Cold joints | Pour delay | Continuous placement |

| Scaling | Freeze-thaw | Air entrainment |

Ready to use the calculator?

→ Launch Calculator