1. Sizing Principles

Control valve sizing determines the valve size needed to pass required flow at specified pressure drop. The goal: select a valve that operates in its controllable range (typically 20–80% open) at normal conditions.

Controllability

20–80% stroke

Keep normal flow in the mid-stroke zone.

ΔP budget

Rule of thirds

Split available ΔP among valve, pipe, and fittings for stable control.

Noise/cavitation

Manage early

Check F_l / x_T, size trim or multi-stage if needed.

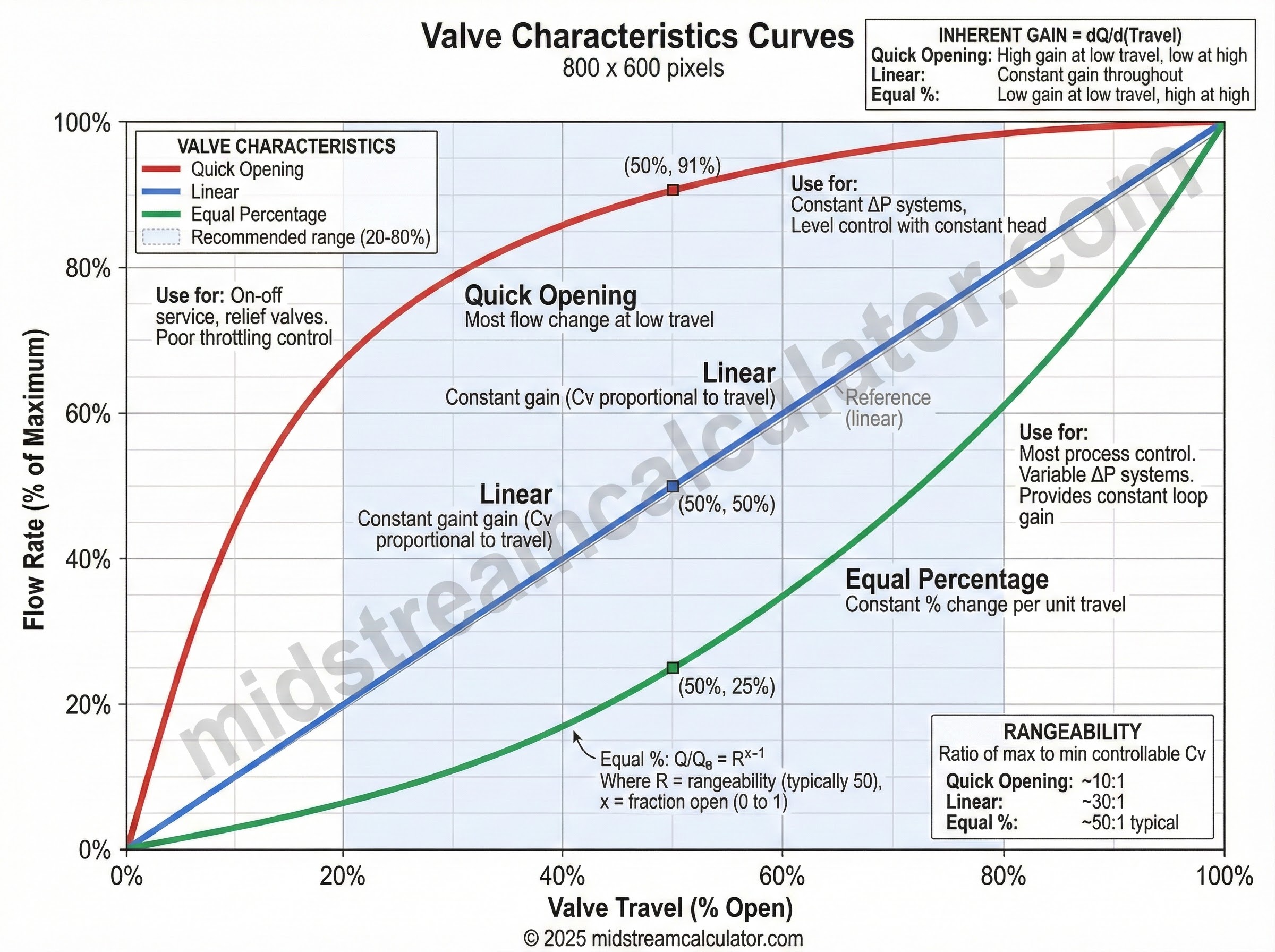

Turn-down

Rangeability

Ball/butterfly for higher rangeability; globe for precision.

Key Sizing Objectives

- Normal operation: Valve 40–60% open at design conditions

- Maximum capacity: Valve can handle 110–120% of design flow

- Minimum controllable flow: Valve provides stable control at turndown

- Rangeability: Ratio of max to min controllable flow (typically 50:1)

2. Flow Coefficient (Cv)

Cv quantifies valve flow capacity. Defined as: gallons per minute of water at 60°F that flows through the valve with 1 psi pressure drop.

Cv vs. Kv

| Coefficient | Units | Conversion |

|---|---|---|

| Cv (US) | GPM with 1 psi ΔP | — |

| Kv (Metric) | m³/hr with 1 bar ΔP | Cv = 1.156 × Kv |

Typical Cv Values

| Valve Size | Globe (Full Port) | Ball (Full Port) | Butterfly |

|---|---|---|---|

| 1" | 10–14 | 30–40 | 35–50 |

| 2" | 40–55 | 130–170 | 150–200 |

| 4" | 160–220 | 500–700 | 700–950 |

| 6" | 350–500 | 1100–1500 | 1500–2100 |

3. Sizing Equations

Liquid Service (Non-Choked)

Gas Service (Subsonic)

Example: Liquid Sizing

Given: 500 GPM water, P1 = 150 psig, P2 = 50 psig

ΔP = 150 - 50 = 100 psi

Cv = 500 × √(1.0 / 100)

Cv = 500 × 0.1 = 50

→ Select 2" globe valve (Cv = 55 @ full open)

Example: Gas Sizing

Given: 1,000,000 SCFH natural gas (SG=0.65), P1 = 500 psia, P2 = 450 psia, T = 100°F

ΔP = 500 - 450 = 50 psi

T = 100 + 460 = 560°R, Z ≈ 0.92

Cv = 1,000,000 / (1360 × 500 × √(50/(0.65 × 560 × 0.92)))

Cv ≈ 42

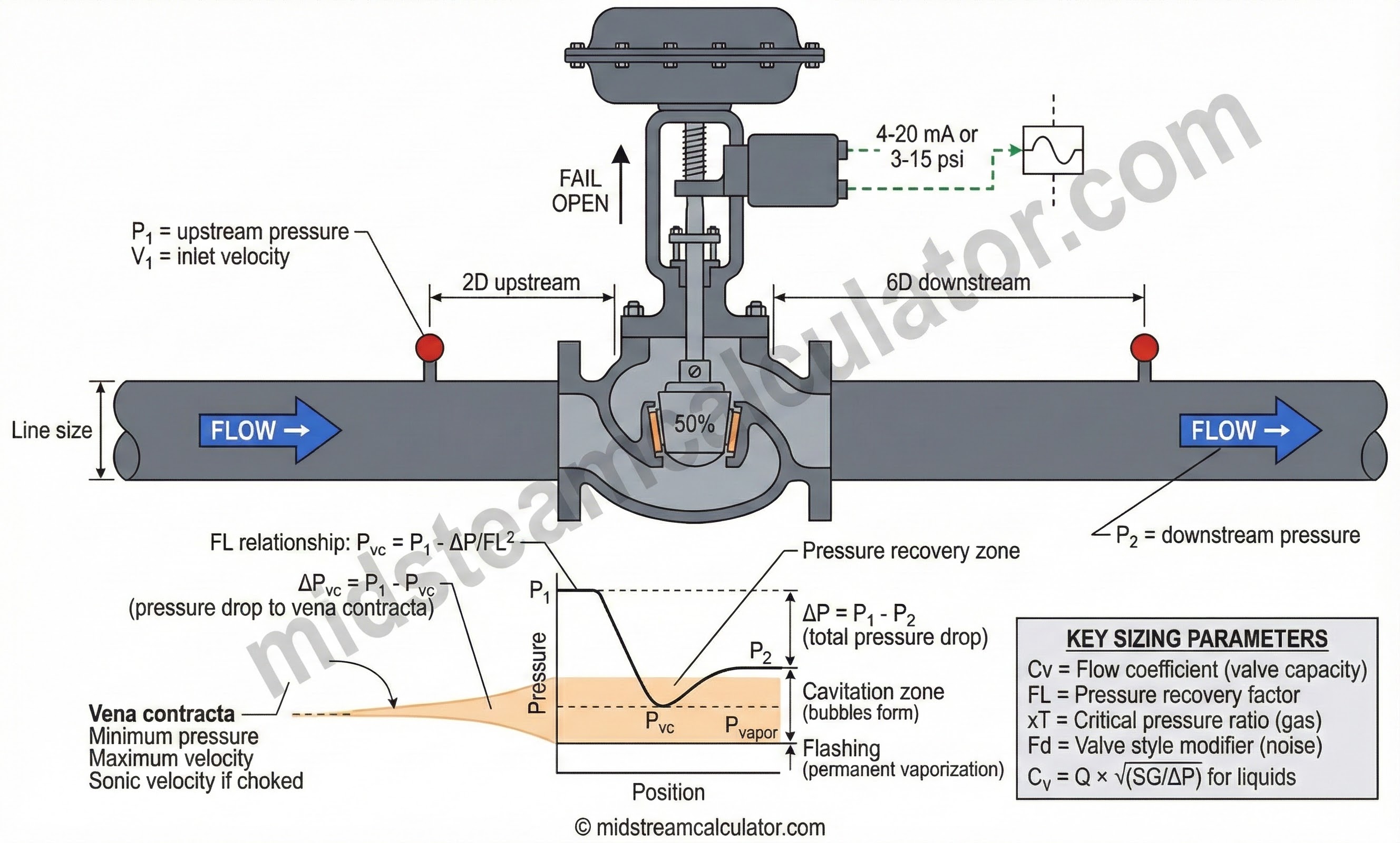

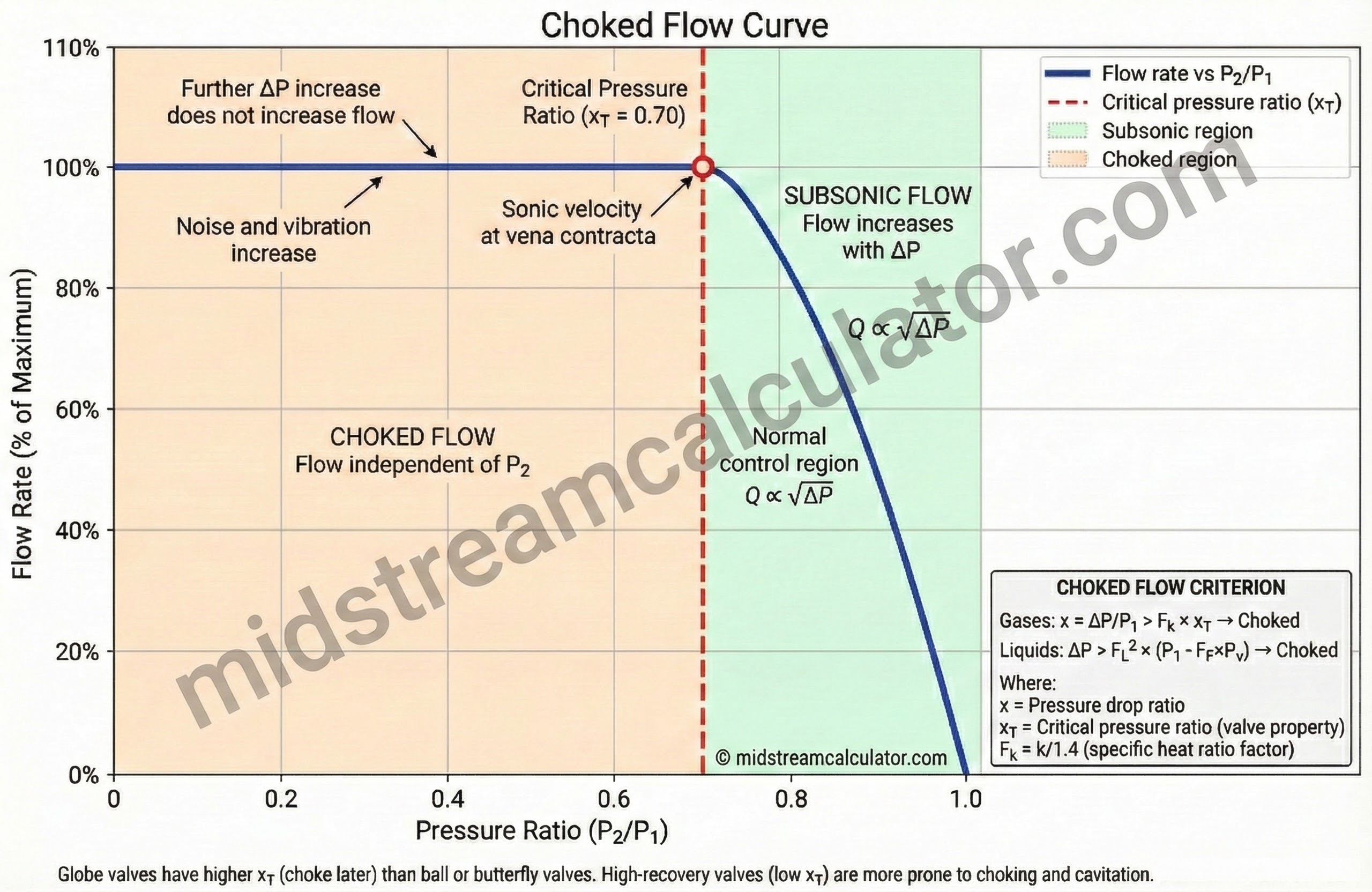

4. Choked Flow

Flow becomes choked when downstream pressure reduction no longer increases flow rate. Velocity reaches sonic limit at the vena contracta.

Critical Pressure Drop

Pressure Recovery Factors

| Valve Type | FL (Liquid) | xT (Gas) |

|---|---|---|

| Globe (parabolic plug) | 0.90 | 0.70–0.75 |

| Globe (equal %) | 0.85 | 0.65–0.70 |

| Ball (V-port) | 0.80 | 0.55–0.65 |

| Butterfly (60° open) | 0.55–0.70 | 0.35–0.50 |

| Ball (full bore) | 0.60 | 0.30–0.40 |

⚠ Cavitation risk: High-recovery valves (low FL) are more prone to cavitation in liquid service. Use anti-cavitation trim or staged pressure reduction for high ΔP applications.

5. Valve Selection

Valve Types

| Type | Best For | Rangeability |

|---|---|---|

| Globe | Throttling, precise control, high ΔP | 50:1 |

| Ball (V-port) | Moderate control, slurries, fibers | 30:1 |

| Butterfly | Large flows, low ΔP, on-off with throttling | 20:1 |

| Rotary plug | High capacity, noise reduction | 50:1 |

Characteristic Selection

- Linear: Use when valve ΔP is constant fraction of system ΔP

- Equal percentage: Use when valve ΔP varies with flow (most process applications)

- Quick opening: On-off or relief service

Selection Checklist

- ☐ Calculate Cv at min, normal, and max conditions

- ☐ Check for choked flow (especially gas service)

- ☐ Select valve size where Cv at normal flow = 40–60% of rated Cv

- ☐ Verify valve can handle max flow at <90% open

- ☐ Check minimum controllable Cv for turndown requirements

- ☐ Evaluate noise and cavitation potential

- ☐ Select appropriate trim and characteristic

References

- ISA-75.01.01 – Flow Equations for Sizing Control Valves

- IEC 60534-2-1 – Industrial Process Control Valves Sizing

- API 609 – Butterfly Valves: Double-Flanged, Lug, and Wafer Type

- ANSI/FCI 70-2 – Control Valve Seat Leakage

6. Piping Geometry Factor (Fp)

When the valve size differs from the pipe size, reducers create additional pressure losses that must be accounted for in sizing. The piping geometry factor Fp corrects the Cv calculation for these fitting losses.

Resistance Coefficients for Reducers

For standard concentric reducers (the most common installation):

| Fitting Type | Resistance Coefficient |

|---|---|

| Inlet reducer (gradual contraction) | K₁ = 0.5 × (1 - d²/D²)² |

| Outlet reducer (sudden expansion) | K₂ = 1.0 × (1 - d²/D²)² |

| Identical inlet and outlet reducers | ΣK = K₁ + K₂ = 1.5 × (1 - d²/D²)² |

Where d = valve size and D = pipe size (both in inches).

Example: Fp Calculation

Given: 3" valve (Cv = 121) in 8" pipe

ΣK = 1.5 × (1 - 9/64)² = 1.5 × (0.859)² = 1.11

Fp = [1 + (1.11/890) × (121/9)²]-½

Fp = [1 + 0.00125 × 180.7]-½

Fp = 0.90

7. Viscosity Correction (FR)

For viscous liquids such as heavy oils, glycol, or polymer solutions, the standard Cv equation underestimates the required valve capacity. The Reynolds number factor FR corrects for viscous flow effects.

When to Apply Viscosity Correction

| Fluid Type | Typical Viscosity (cP) | FR Impact |

|---|---|---|

| Water | 1 | FR ≈ 1.0 (no correction) |

| Light crude oil | 5–20 | FR ≈ 1.0–1.02 |

| Ethylene glycol | 20–50 | FR ≈ 1.02–1.05 |

| Heavy crude oil | 100–500 | FR ≈ 1.05–1.20 |

| Fuel oil #6 | 500–2000 | FR ≈ 1.20–1.50 |

⚠ High viscosity caution: For fluids above 500 cP, valve selection becomes critical. Globe valves with large clearances are preferred. Avoid tight-shutoff designs that may stick or require excessive actuator force.

8. Seat Leakage Classifications

Control valve seat leakage is classified per ANSI/FCI 70-2 and IEC 60534-4. The appropriate leakage class depends on process requirements, safety considerations, and economic factors.

| Class | Maximum Leakage | Test Medium | Typical Application |

|---|---|---|---|

| I | No test required | — | Non-critical service |

| II | 0.5% of rated Cv | Air or water | General service, double-ported valves |

| III | 0.1% of rated Cv | Air or water | Single-seat valves, standard trim |

| IV | 0.01% of rated Cv | Air or water | Single-seat valves, tight shutoff |

| V | 0.0005 mL/min per inch port diameter per psi ΔP | Water | High-integrity shutoff, soft seats |

| VI | Bubble-tight (see table below) | Air or N₂ | Emergency shutoff, isolation valves |

Class VI Leakage Rates by Port Size

| Port Diameter | Max Leakage (mL/min) | Bubbles/min |

|---|---|---|

| ≤ 1 inch | 0.15 | 1 |

| 1.5 inch | 0.30 | 2 |

| 2 inch | 0.45 | 3 |

| 2.5 inch | 0.60 | 4 |

| 3 inch | 0.90 | 6 |

| 4 inch | 1.70 | 11 |

| 6 inch | 4.00 | 27 |

Leakage Class Selection Guide

- Class II–III: Standard process control where some leakage is acceptable

- Class IV: Most single-seat globe valves; adequate for typical process isolation

- Class V: Critical applications requiring minimal leakage; soft-seated valves

- Class VI: Safety shutoff, toxic/flammable service, environmental compliance

Ready to use the calculator?

→ Launch Calculator