Calculation Mode:

Size vent for blow-by gas from failed-open control valves (PHA scenario)

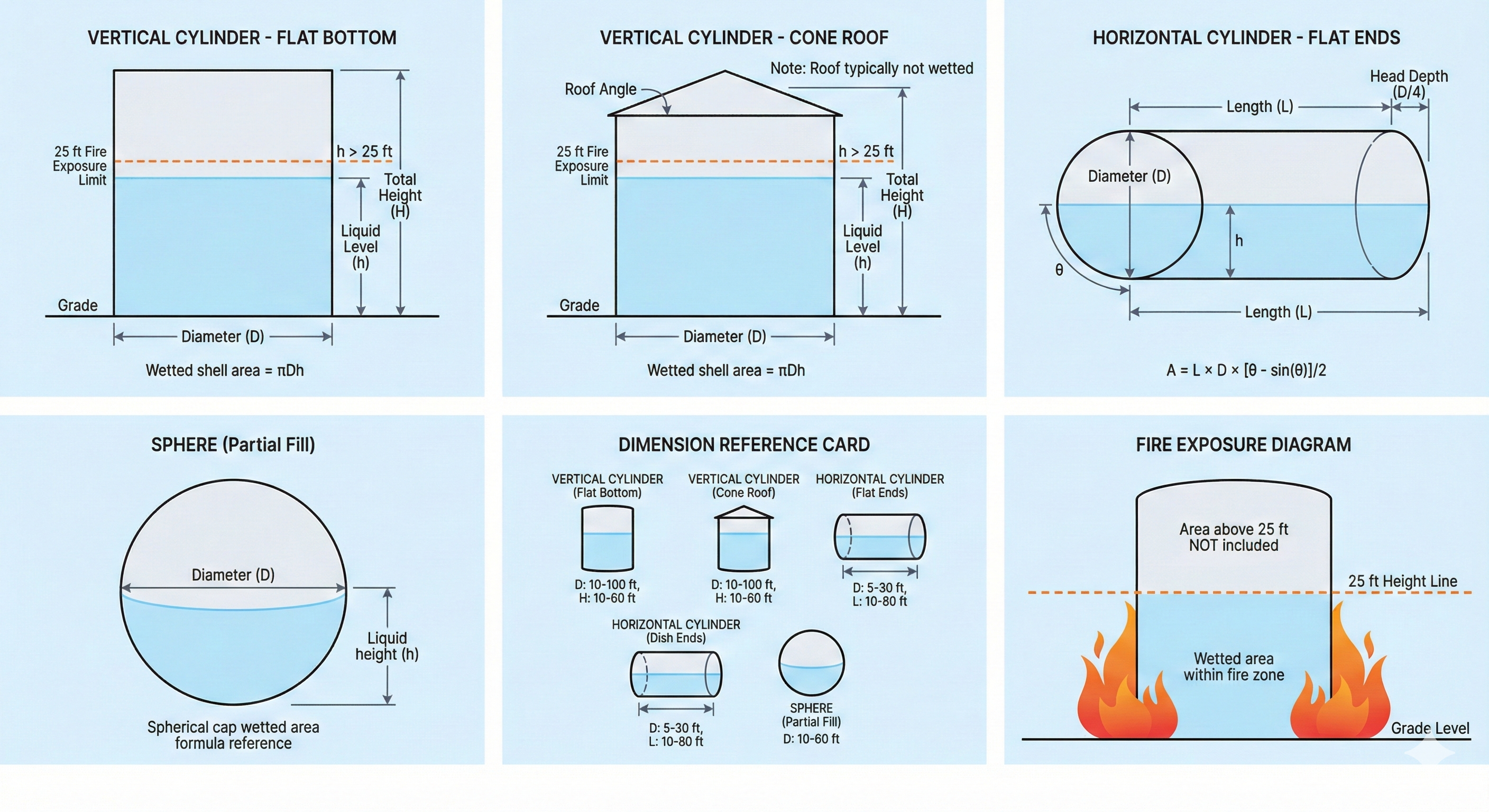

Tank Configuration

Blow-By Gas Source

psig

Cv

in (ID)

ft

in

Gas Properties

°F

Typical Tank Pressure Ratings

API 650 (standard)1 oz/in²

API 650 Annex F2.5–15 psig

Low-pressure tanks0.5–1.0 psig

Learn the Theory

API 2000 methodology, thermal breathing, blow-by scenarios, and emergency venting

Engineering Basis

Blow-By Scenario (PHA)

Vent Area = Q × √(SG × T) / (C × K × P)

Gas flow from failed-open control valve through restriction orifice to atmospheric tank. Critical for tank vent sizing.

API 2000 Thermal Inbreathing

V_IT = C × (V_tk)^0.7 × R_i

Thermal contraction during cooling. C depends on vapor pressure, latitude, and storage temp.