1. Volume Calculation

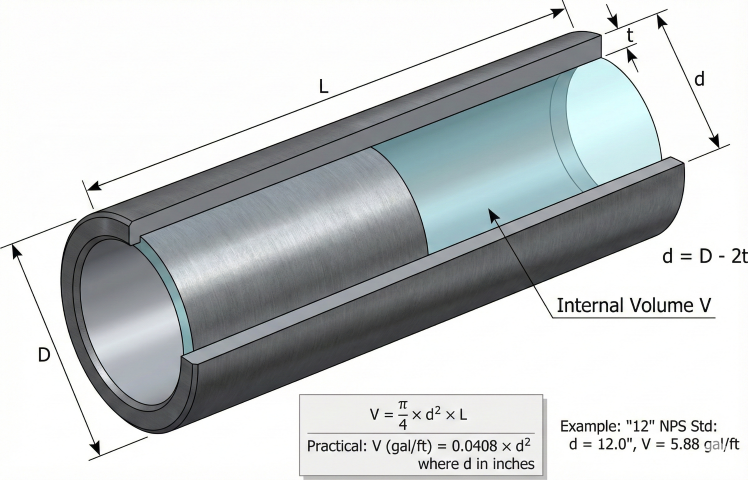

Pipe internal volume is calculated from the inside diameter and length. Various unit conversions are needed for practical applications.

Basic Formulas

Inside Diameter

Unit Conversions

| From | To | Multiply by | Source |

|---|---|---|---|

| ft³ | US gallons | 7.480519 | API MPMS |

| ft³ | barrels (42 gal) | 0.178108 | API |

| gallons | barrels | 0.023810 | API |

| ft³ | liters | 28.31685 | NIST |

| gallons | liters | 3.785412 | NIST |

| barrels | liters | 158.987 | API |

2. Volume Reference Tables

Standard Pipe Volumes

| NPS | OD (in) | Wall (Std) | ID (in) | gal/ft | bbl/mile |

|---|---|---|---|---|---|

| 2" | 2.375 | 0.154 | 2.067 | 0.174 | 21.9 |

| 4" | 4.500 | 0.237 | 4.026 | 0.661 | 83.4 |

| 6" | 6.625 | 0.280 | 6.065 | 1.501 | 189.4 |

| 8" | 8.625 | 0.322 | 7.981 | 2.599 | 327.9 |

| 10" | 10.750 | 0.365 | 10.020 | 4.098 | 517.0 |

| 12" | 12.750 | 0.375 | 12.000 | 5.875 | 741.2 |

| 16" | 16.000 | 0.375 | 15.250 | 9.489 | 1,197 |

| 20" | 20.000 | 0.375 | 19.250 | 15.12 | 1,907 |

| 24" | 24.000 | 0.375 | 23.250 | 22.05 | 2,782 |

| 30" | 30.000 | 0.375 | 29.250 | 34.90 | 4,403 |

| 36" | 36.000 | 0.375 | 35.250 | 50.71 | 6,398 |

| 42" | 42.000 | 0.500 | 41.000 | 68.60 | 8,655 |

Quick Reference: Volume per Mile

3. Gas Volume at Pressure

For gas pipelines, volume must account for compressibility. The actual gas quantity depends on pressure, temperature, and gas composition.

Gas Inventory Calculation

Z-Factor Estimation

The compressibility factor Z accounts for real gas behavior. For natural gas:

Line Pack Formula

Example: Gas Pipeline Inventory

Given: 24" × 0.500" wall, 100 miles, P_avg = 800 psia, T = 70°F, SG = 0.60

Step 1: Physical volume

ID = 24 - 2(0.500) = 23 in

V = 0.00545 × 23² × 5,280 × 100 = 15.23 MM ft³

Step 2: Z-factor (from DAK correlation)

T_pc = 169.2 + 349.5(0.60) - 74.0(0.36) = 352.5°R

P_pc = 756.8 - 131.0(0.60) - 3.6(0.36) = 676.8 psia

T_pr = 530/352.5 = 1.50; P_pr = 800/676.8 = 1.18

Z ≈ 0.87

Step 3: Line pack

SCF = 15.23×10⁶ × 800 × 35.34 / (530 × 0.87)

SCF = 934 MMSCF

4. Applications

Common Uses

| Application | Purpose |

|---|---|

| Hydrotesting | Calculate water volume needed for test |

| Purging/inerting | Determine nitrogen volume for displacement |

| Pigging | Estimate pig travel time at given flow rate |

| Batch tracking | Calculate batch interface location |

| Line pack | Gas storage capacity in pipeline |

| Blowdown | Gas release volume for depressuring |

| Chemical treatment | Inhibitor/biocide dosing volume |

Hydrotest Water Requirements

Pig Travel Time

5. System Volume

Total system volume includes pipe plus vessels, headers, and fittings.

Vessel Volumes

Fitting Equivalent Volumes

| Fitting | Equivalent Pipe Length |

|---|---|

| 90° elbow (LR) | 1.5 × D |

| 90° elbow (SR) | 1.0 × D |

| 45° elbow | 0.7 × D |

| Tee (through) | 1.0 × D |

| Tee (branch) | 1.5 × D |

| Gate valve (open) | 0.5 × D |

| Ball valve (open) | 0.1 × D |

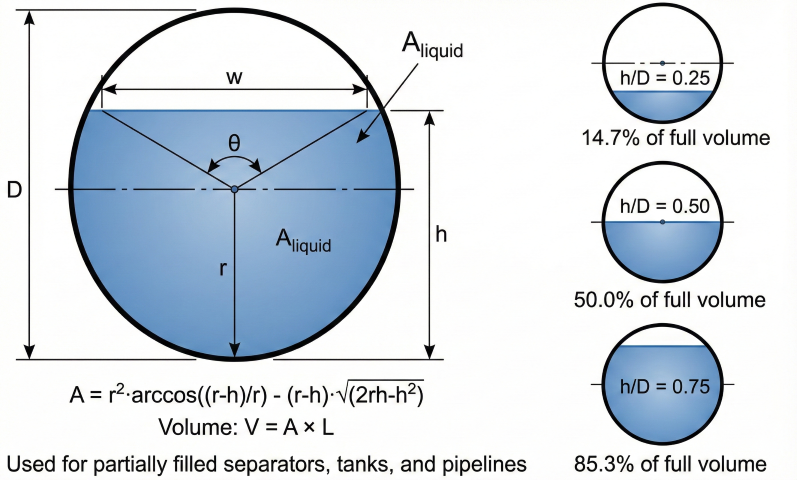

Partially Filled Horizontal Pipe

References

- ASME B36.10M – Welded and Seamless Wrought Steel Pipe

- API MPMS Chapter 11.1 – Temperature and Pressure Volume Correction

- AGA Report No. 8 – Compressibility and Supercompressibility Factors

- GPSA, Section 17 – Fluid Properties

- Dranchuk & Abou-Kassem (1975) – Z-Factor Calculation Methods

- Sutton (1985) – Pseudo-Critical Property Correlations

Ready to use the calculator?

→ Launch Calculator