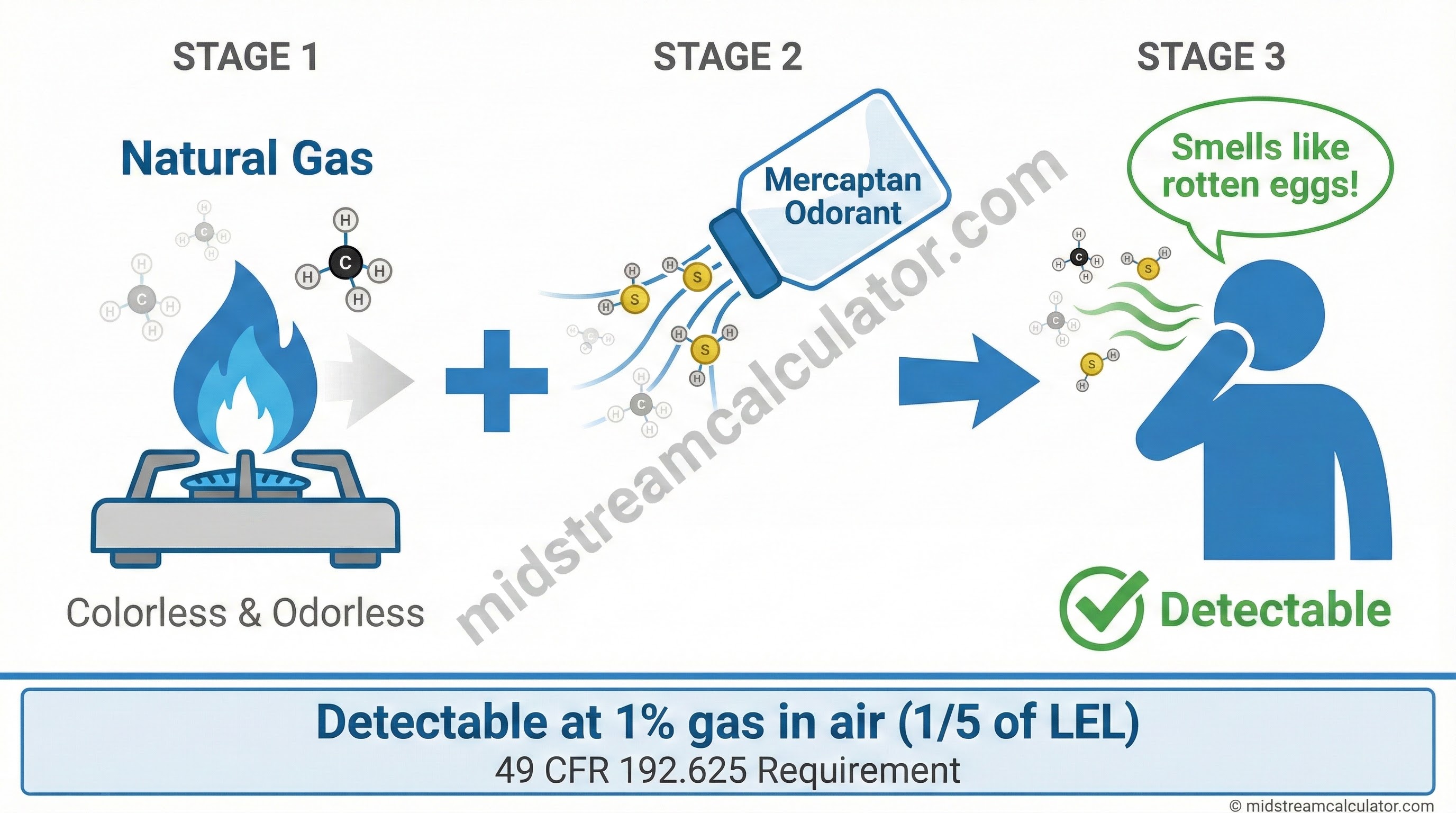

1. Why Odorize Natural Gas?

Natural gas (primarily methane) is colorless and odorless. Without odorization, leaks are undetectable until gas reaches dangerous concentrations. The 1937 New London School explosion in Texas—which killed over 295 people due to an undetected gas leak—led to mandatory odorization requirements.

2. Regulatory Requirements

49 CFR 192.625 — The Federal Standard

What "Readily Detectable" Means

Per PHMSA interpretations, "readily detectable" means a typical person (spouse, family member, or member of the public) would quickly recognize the odor and take appropriate action—without hesitation or difficulty.

Applicability

| Pipeline Type | Odorization Required? |

|---|---|

| Distribution lines | Yes — Always required |

| Service lines | Yes — Part of distribution system |

| Transmission lines (Class 3 & 4) | Yes — Unless exempted |

| Transmission lines (Class 1 & 2) | Generally exempt (check state rules) |

| Industrial feedstock | Exempt if meets criteria |

Periodic Sampling (192.625(f))

Operators must conduct periodic sampling using instruments capable of determining the percentage of gas in air at which odor becomes readily detectable. Common instruments include the Heath Odorator, YZ DTEX, and Bacharach Odorometer.

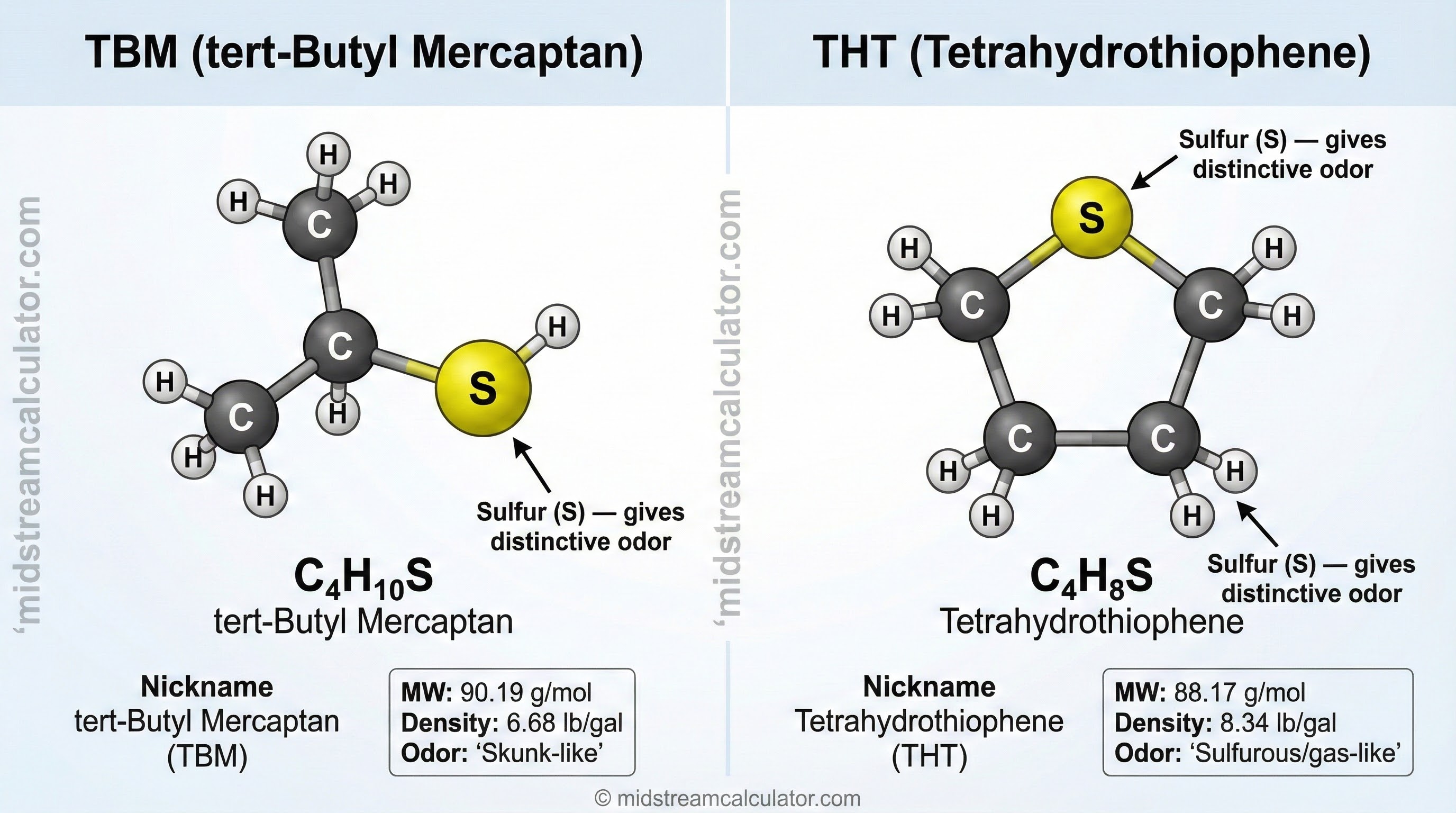

3. Odorant Types & Properties

Gas odorants are organosulfur compounds selected for their intense odor at very low concentrations, chemical stability, and compatibility with pipeline materials.

Common Odorants

| Odorant | Formula | MW (g/mol) | Density (lb/gal) | Primary Use |

|---|---|---|---|---|

| TBM tert-Butyl Mercaptan |

C₄H₁₀S | 90.19 | 6.68 | Most common in North America |

| THT Tetrahydrothiophene |

C₄H₈S | 88.17 | 8.34 | Common in Europe; cyclic structure more stable |

| DMS Dimethyl Sulfide |

C₂H₆S | 62.13 | 7.26 | Blending component; lower freeze point |

| Blends Scentinel®, SPOTLEAK® |

Various | 85–90 | 6.8–7.1 | Optimized for specific applications |

Selection Criteria

- Odor threshold — Detectable at sub-ppb levels

- Stability — Resistant to oxidation in pipeline

- Vapor pressure — Similar to natural gas (prevents dropout)

- Non-corrosive — Safe for pipe, valves, meters

- Soil penetration — Detectable through soil for buried leaks

4. Injection Rate Calculations

Basic Formulas

Example Calculation

Mass rate: 10 × 0.25 = 2.5 lb/day

Volume rate: 2.5 ÷ 6.68 = 0.374 gal/day

Annual: 0.374 × 365 = 137 gal/year ≈ 3 drums

Pump Stroke Calculation

For positive-displacement pumps with known stroke volume:

Unit Conversion Reference

Precise conversion: ppm = (lb/MMCF × 385) ÷ MW

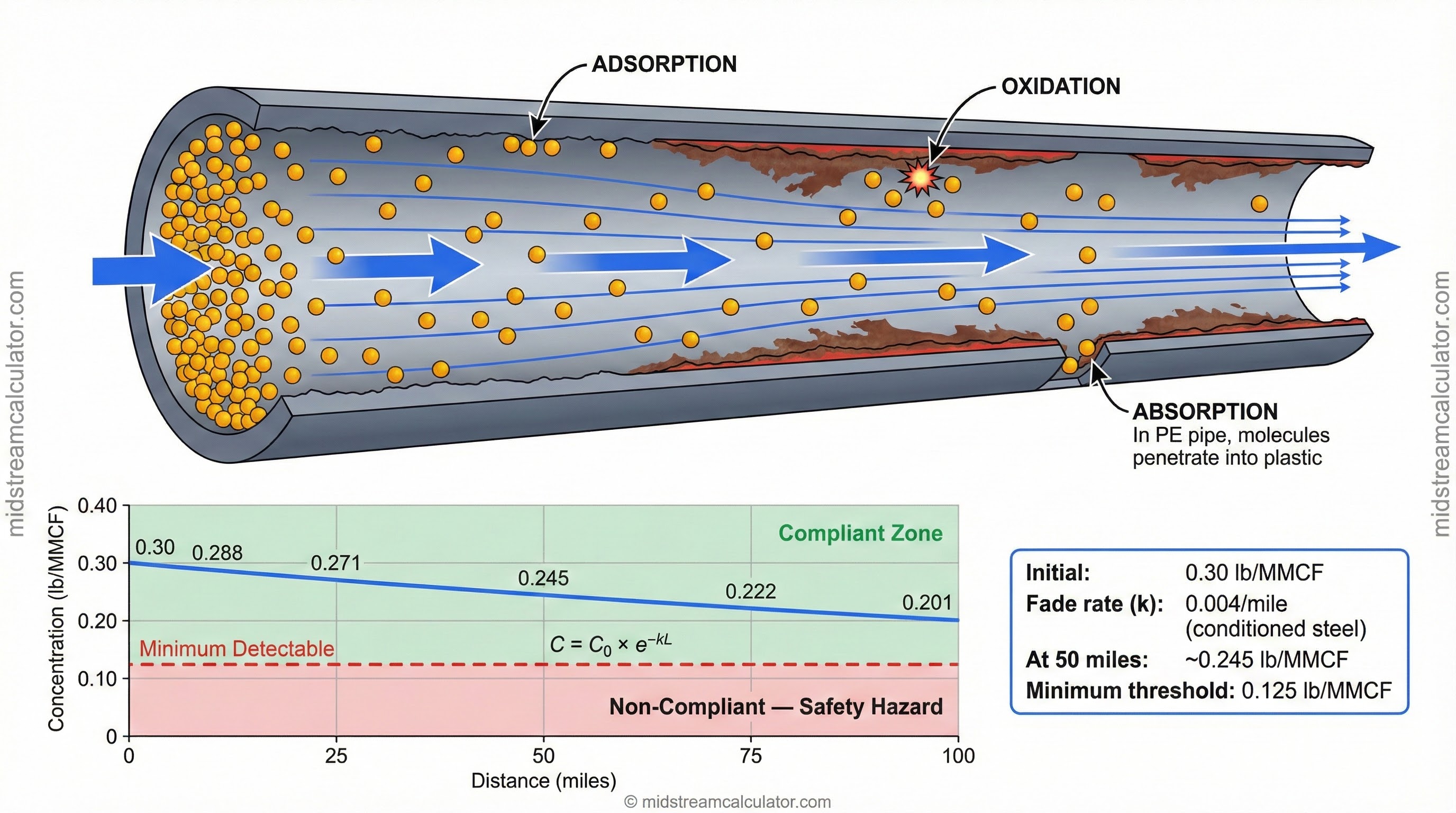

5. Odorant Fade

Odorant fade is the reduction in odorant concentration as gas travels through the pipeline. If unchecked, fade can drop concentrations below detectable limits—a serious safety hazard.

Fade Mechanisms

| Mechanism | Description | Most Affected |

|---|---|---|

| Adsorption | Molecules adhere to pipe wall surface | New steel, new PE |

| Absorption | Molecules penetrate into pipe material | Polyethylene (PE) |

| Oxidation | Chemical reaction with rust (iron oxides) | Rusty steel, cast iron |

| Catalysis | Metal-catalyzed mercaptan decomposition | Copper tubing |

Fade by Pipe Material

| Material | Fade Rate (k) | Mitigation |

|---|---|---|

| Steel (New) | High initially | Pre-condition ("pickle") with high-dose odorant before service |

| Steel (Conditioned) | Low | Normal injection rates sufficient |

| Polyethylene (PE) | Moderate | Higher injection rates; THT absorbs less than TBM |

| Cast Iron | Moderate–High | Increase injection; consider pipe replacement |

| Copper | Very High | Avoid mercaptans; use alternative odorants or avoid copper |

Fade Model

Fade follows exponential decay:

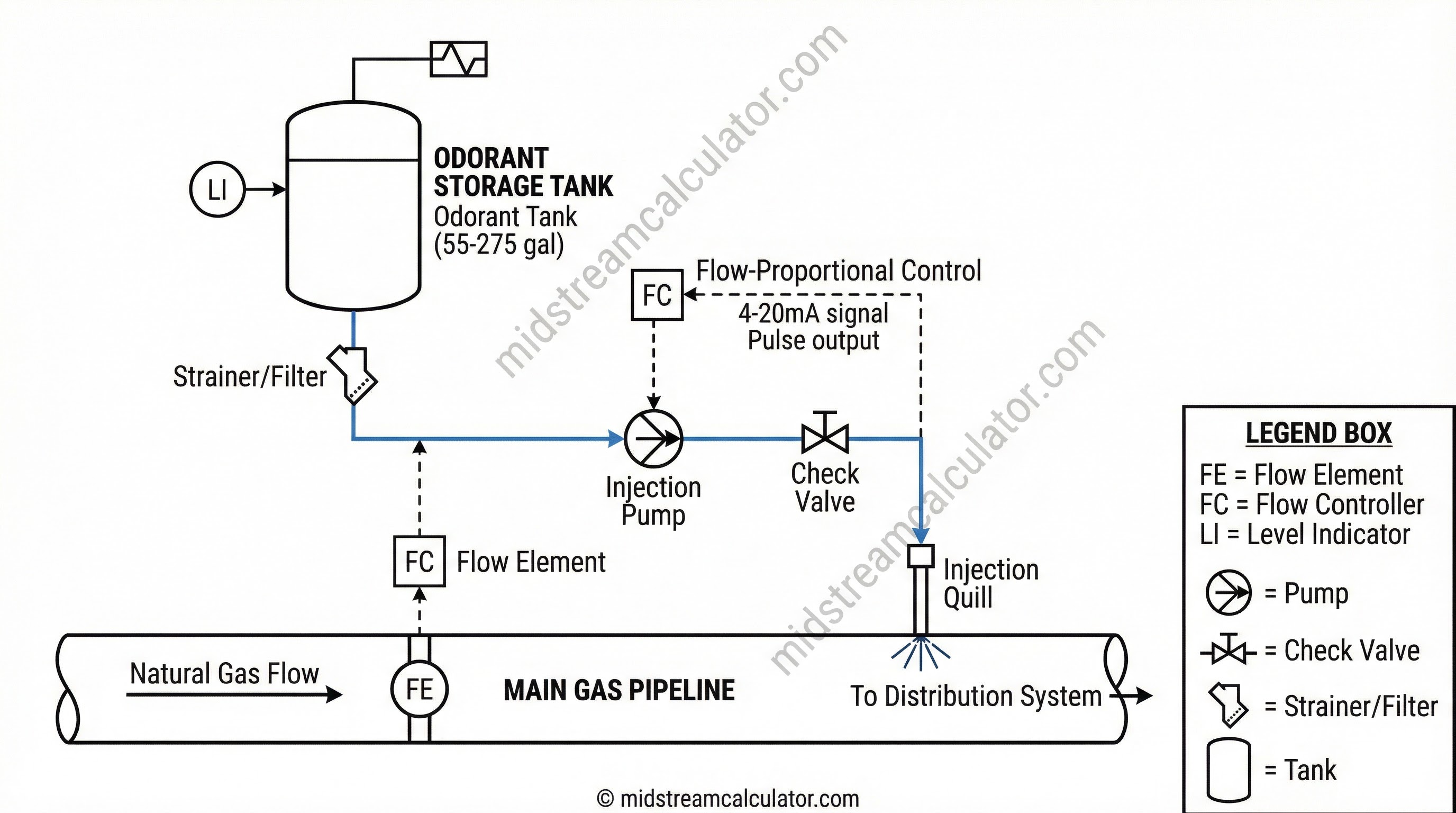

6. Equipment & Monitoring

Injection System Types

| Type | Best For | Pros | Cons |

|---|---|---|---|

| Bypass/Wick | Very low, steady flow | Simple, no power needed | Inaccurate, temp-sensitive |

| Fixed-Rate Pump | Steady flow systems | Reliable, low maintenance | Can't adapt to flow changes |

| Flow-Proportional | Variable flow | Maintains concentration automatically | Requires flow measurement |

| Electronic/SCADA | Critical systems | Remote monitoring, alarms, logging | Higher cost, complexity |

Injection Point Selection

- Locate upstream of all customer delivery points

- Allow ≥10 pipe diameters downstream for mixing

- Position after pressure regulators (avoid pressure fluctuations)

- Ensure accessibility for maintenance and tank refills

- Protect from freezing (TBM freezes at 32°F / 0°C)

Monitoring & Compliance

Spot Checks: Trained personnel perform "sniff tests" at system extremities using calibrated instruments. Document location, date, instrument reading, and pass/fail result.

Analytical Testing: Gas chromatography provides precise concentration measurement. Recommended for new systems, after changes, and when spot checks show anomalies.

Action Threshold: If concentration deviates >10% from target, investigate cause and adjust injection rate.

Reference Standards

Federal odorization requirements for gas pipelines

Standard Test Methods for Natural Gas Odor Intensity

Test Method for Mercaptans in Natural Gas (Detector Tubes)

American Gas Association design guidelines

Ready to use the calculator?

→ Launch Calculator