1. SI Unit System Overview

The International System of Units (SI) is the modern form of the metric system and the most widely used system of measurement worldwide. Understanding both SI and imperial (US Customary) units is essential for midstream engineers working on international projects.

Base units

Seven fundamentals

meter, kilogram, second, ampere, kelvin, mole, candela.

Derived units

Combinations

Pascal (pressure), Joule (energy), Watt (power) from base units.

Decimal system

Powers of 10

kilo (10³), mega (10⁶), milli (10⁻³), micro (10⁻⁶) prefixes.

Global standard

ISO compliance

ISO 80000 series defines SI units for engineering applications.

SI Base Units

| Quantity | SI Unit | Symbol | Imperial Equivalent |

|---|---|---|---|

| Length | meter | m | 3.281 feet |

| Mass | kilogram | kg | 2.205 pounds |

| Time | second | s | 1 second (same) |

| Temperature | kelvin | K | °R (Rankine) / 1.8 |

| Amount of substance | mole | mol | 1 lb-mol = 453.6 mol |

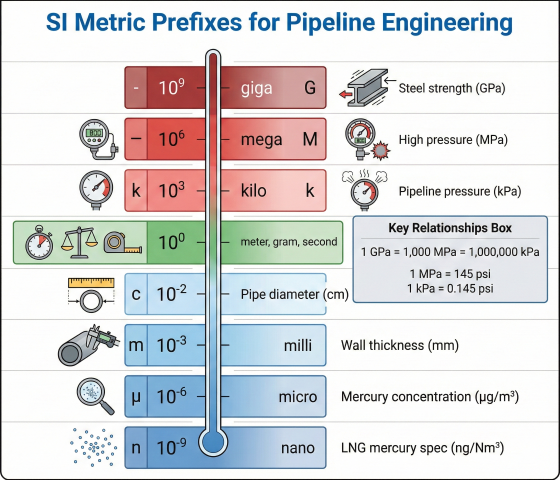

Common SI Prefixes

| Prefix | Symbol | Factor | Example (Pipeline/Gas) |

|---|---|---|---|

| giga | G | 10⁹ | GPa (pipe yield strength, 1 GPa = 145,000 psi) |

| mega | M | 10⁶ | MPa (pressure, 1 MPa = 145 psi) |

| kilo | k | 10³ | kPa (pressure, 1 kPa = 0.145 psi) |

| centi | c | 10⁻² | cm (diameter, 1 cm = 0.394 in) |

| milli | m | 10⁻³ | mm (pipe wall thickness, 1 mm = 0.0394 in) |

| micro | µ | 10⁻⁶ | µg (mercury concentration, 1 µg = 1 × 10⁻⁶ g) |

| nano | n | 10⁻⁹ | ng (LNG mercury spec, 1 ng = 1 × 10⁻⁹ g) |

Imperial (US Customary) System

The imperial system remains prevalent in United States pipeline and midstream operations:

- Length: inch (in), foot (ft), mile (mi)

- Mass: pound (lb), ton (2000 lb)

- Force: pound-force (lbf) — distinct from pound-mass (lbm)

- Pressure: psi (lb/in²), psig (gauge), psia (absolute)

- Temperature: Fahrenheit (°F), Rankine (°R = °F + 459.67)

- Volume: cubic foot (ft³), gallon (gal), barrel (bbl = 42 gal)

2. Length & Area Conversions

Length conversions are fundamental for pipe sizing, distance measurements, and area calculations in pipeline engineering.

Length Conversion Factors

Comprehensive Length Conversion Table

| From | To | Multiply By | Example |

|---|---|---|---|

| inches | millimeters | 25.4 | 24 in × 25.4 = 609.6 mm (24" pipe OD) |

| inches | centimeters | 2.54 | 36 in × 2.54 = 91.44 cm |

| feet | meters | 0.3048 | 100 ft × 0.3048 = 30.48 m (pipe segment) |

| miles | kilometers | 1.60934 | 50 mi × 1.60934 = 80.47 km (pipeline length) |

| millimeters | inches | 0.03937 | 12.7 mm × 0.03937 = 0.500 in (wall thickness) |

| meters | feet | 3.28084 | 10 m × 3.28084 = 32.81 ft |

| kilometers | miles | 0.621371 | 100 km × 0.621371 = 62.14 mi |

Area Conversions

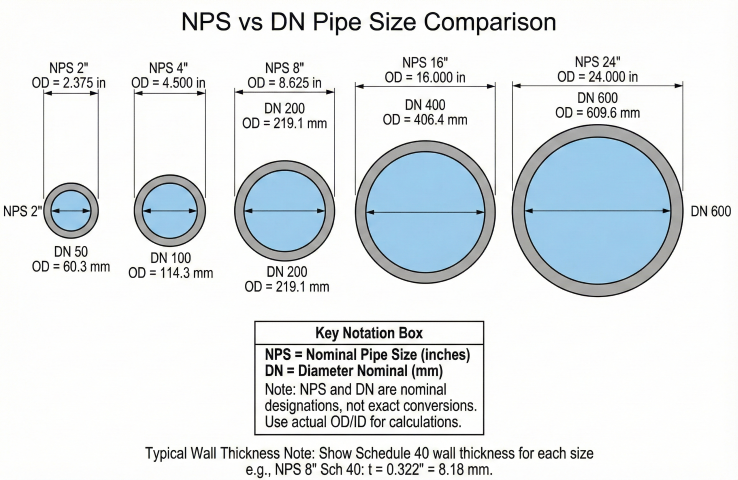

Pipe Size Conversions (NPS to DN)

| NPS (Nominal Pipe Size) | OD (inches) | DN (Diameter Nominal) | OD (mm) |

|---|---|---|---|

| 2" | 2.375 | DN 50 | 60.3 |

| 4" | 4.500 | DN 100 | 114.3 |

| 6" | 6.625 | DN 150 | 168.3 |

| 8" | 8.625 | DN 200 | 219.1 |

| 12" | 12.750 | DN 300 | 323.9 |

| 16" | 16.000 | DN 400 | 406.4 |

| 20" | 20.000 | DN 500 | 508.0 |

| 24" | 24.000 | DN 600 | 609.6 |

| 36" | 36.000 | DN 900 | 914.4 |

| 42" | 42.000 | DN 1050 | 1066.8 |

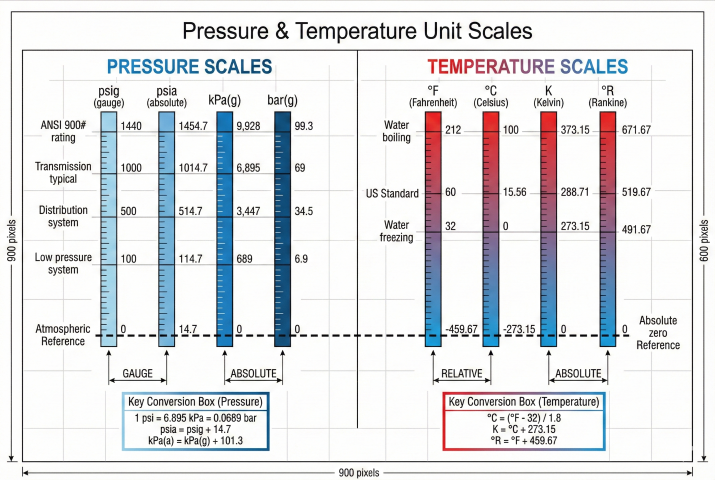

3. Pressure & Temperature Conversions

Pressure and temperature conversions are critical for all pipeline and process calculations. Understanding absolute vs gauge pressure and temperature scale offsets is essential.

Pressure Conversion Factors

Pressure Conversion Table

| From | To | Multiply By | Example (Pipeline) |

|---|---|---|---|

| psi | kPa | 6.89476 | 1000 psig × 6.895 = 6895 kPa(g) |

| psi | bar | 0.0689476 | 1000 psi × 0.06895 = 68.95 bar |

| psi | MPa | 0.00689476 | 1440 psi × 0.006895 = 9.93 MPa (ANSI 900#) |

| kPa | psi | 0.145038 | 10,000 kPa × 0.145 = 1450 psi |

| bar | psi | 14.5038 | 70 bar × 14.5 = 1015 psi (pipeline MAOP) |

| MPa | psi | 145.038 | 15 MPa × 145 = 2176 psi |

| in H₂O | kPa | 0.248844 | 100 in H₂O × 0.249 = 24.9 kPa (orifice ΔP) |

| mm Hg | kPa | 0.133322 | 760 mm Hg × 0.133 = 101.3 kPa (1 atm) |

Temperature Conversions

Common Temperature Conversions

| °F | °C | K | °R | Typical Application |

|---|---|---|---|---|

| -40 | -40 | 233.15 | 419.67 | Low-temperature gas processing |

| 32 | 0 | 273.15 | 491.67 | Hydrate formation reference |

| 60 | 15.56 | 288.71 | 519.67 | US standard conditions |

| 70 | 21.11 | 294.26 | 529.67 | Typical ambient (design) |

| 100 | 37.78 | 310.93 | 559.67 | Summer pipeline temperature |

| 150 | 65.56 | 338.71 | 609.67 | Compressor discharge (typical) |

| 212 | 100 | 373.15 | 671.67 | Water boiling point (1 atm) |

Worked Example: Combined Conversion

4. Flow Rate & Volume Conversions

Flow rate and volume conversions are essential for production reporting, pipeline capacity calculations, and custody transfer.

Volumetric Flow Rate Conversions

Gas Flow Rate Conversion Table

| From | To | Multiply By | Example |

|---|---|---|---|

| scfd | Sm³/d | 0.0283168 | 100,000 scfd × 0.0283 = 2,832 Sm³/d |

| MMscfd | Sm³/d | 28,316.8 | 50 MMscfd × 28,317 = 1,415,840 Sm³/d |

| MMscfd | Sm³/h | 1,179.9 | 10 MMscfd × 1,180 = 11,800 Sm³/h |

| scfm | Sm³/h | 1.699 | 1,000 scfm × 1.699 = 1,699 Sm³/h |

| Sm³/d | scfd | 35.3147 | 10,000 Sm³/d × 35.31 = 353,147 scfd |

| Sm³/h | MMscfd | 0.000847 | 50,000 Sm³/h × 0.000847 = 42.4 MMscfd |

Liquid Flow Rate Conversions

Volume Conversions

| From | To | Multiply By | Application |

|---|---|---|---|

| ft³ | m³ | 0.0283168 | Vessel volumes, pipeline inventory |

| barrel (bbl) | m³ | 0.158987 | Oil/NGL storage, production |

| gallon (US) | liter | 3.78541 | Chemical injection, small volumes |

| in³ | cm³ (mL) | 16.3871 | Laboratory samples |

| m³ | ft³ | 35.3147 | Reverse conversion |

| m³ | barrel | 6.28981 | Reverse conversion |

| liter | gallon | 0.264172 | Reverse conversion |

Mass Flow Rate Conversions

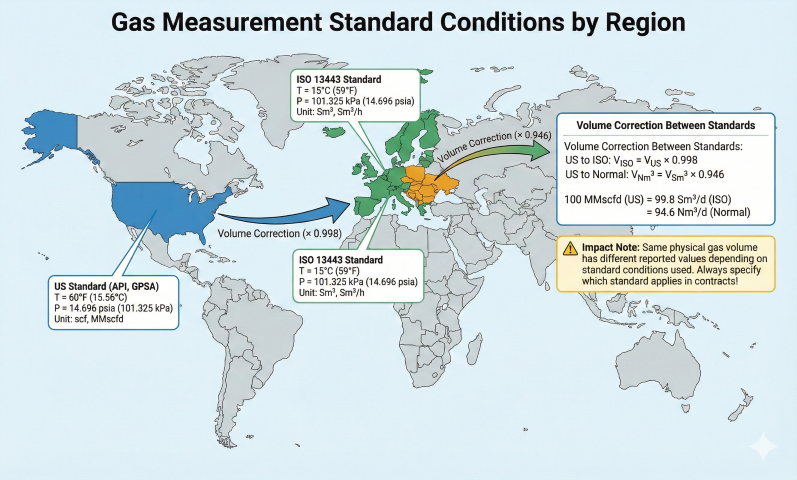

5. Standard Conditions & Unit Consistency

Standard conditions for gas measurement vary by region and industry. Understanding these differences is critical for accurate flow rate reporting and contract compliance.

Standard Condition Definitions

| Standard | Temperature | Pressure | Application |

|---|---|---|---|

| US (API, GPSA) | 60°F (15.56°C) | 14.696 psia (101.325 kPa) | US pipeline contracts, API standards |

| ISO 13443 | 15°C (59°F) | 101.325 kPa (14.696 psia) | International standard, LNG contracts |

| Normal (European) | 0°C (32°F) | 101.325 kPa (14.696 psia) | European pipeline systems |

| CAGI (compressed air) | 68°F (20°C) | 14.5 psia (100 kPa) | Compressed air systems (not natural gas) |

| SPE (petroleum) | 60°F (15.56°C) | 14.65 psia (101 kPa) | Some reservoir engineering applications |

Impact of Standard Condition Differences

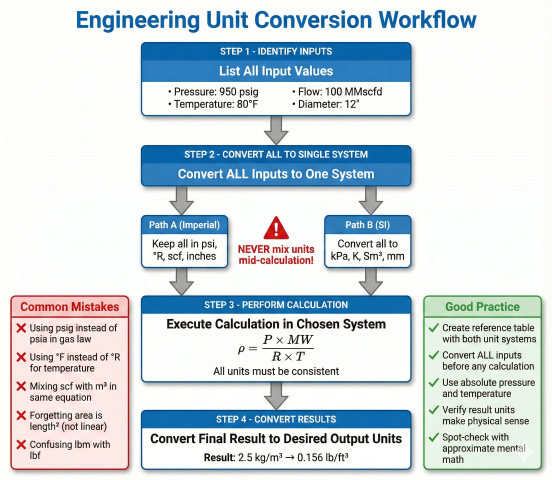

Unit Consistency in Calculations

Common pitfalls and how to avoid them:

Density Conversion Factors

| From | To | Multiply By | Common Value |

|---|---|---|---|

| lb/ft³ | kg/m³ | 16.0185 | Natural gas: 0.05 lb/ft³ = 0.80 kg/m³ |

| lb/gal | kg/L (or SG) | 0.11983 | Water: 8.34 lb/gal = 1.0 kg/L |

| API gravity | SG (specific gravity) | SG = 141.5/(API+131.5) | 40°API oil = 0.825 SG |

| lb/bbl | kg/m³ | 2.8531 | Condensate: 300 lb/bbl = 856 kg/m³ |

Energy Conversions

Viscosity Conversions

| From | To | Multiply By | Example |

|---|---|---|---|

| cP (centipoise) | Pa·s | 0.001 | Gas: 0.011 cP = 1.1 × 10⁻⁵ Pa·s |

| lb/(ft·s) | Pa·s | 1.48816 | Oil: 0.001 lb/(ft·s) = 0.00149 Pa·s |

| cSt (centistokes) | m²/s | 1 × 10⁻⁶ | Kinematic: 10 cSt = 1 × 10⁻⁵ m²/s |

Common Conversion Mistakes

- Forgetting absolute pressure: Using 1000 psig in gas law instead of 1014.7 psia (1.5% error)

- Mixing °F and °R: Using °F directly in PV = nRT (causes ~65% error at 60°F)

- Confusing scf and cf: Standard cubic feet (scf) at base conditions vs actual cubic feet (acf) at flowing conditions

- Ignoring standard condition differences: Assuming US standard when contract specifies ISO (0.2% error)

- Mass vs force units: Using lbm and lbf interchangeably (requires g_c = 32.174 lb·ft/(lbf·s²) conversion)

- Area conversions: Using linear conversion for area (1 ft = 0.3048 m, but 1 ft² = 0.0929 m², not 0.3048 m²)

Ready to use the calculator?

→ Open Engineering Unit Converter