1. The Joule-Thomson Effect

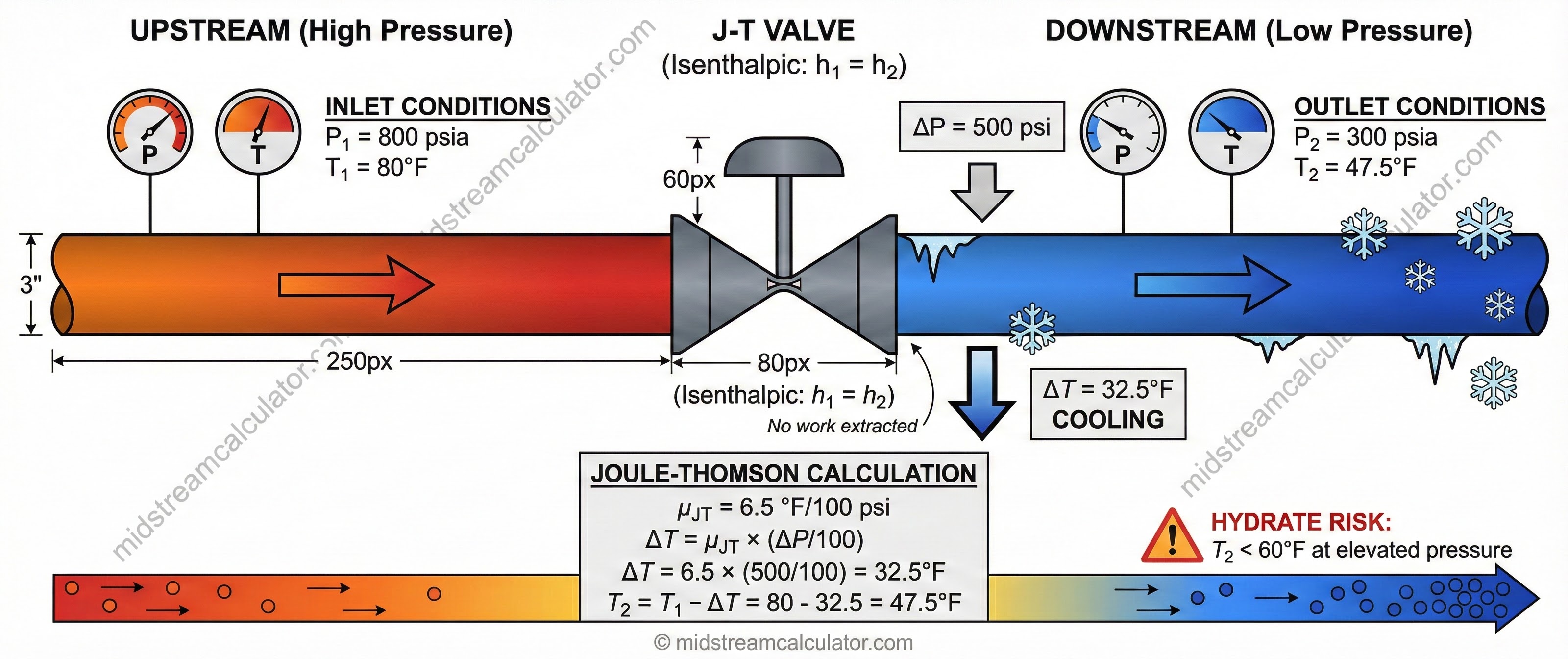

Gas expanding through a valve without external work (isenthalpic process) changes temperature. Natural gas at typical conditions cools on expansion.

Sign Convention

| Condition | μ_JT | Effect |

|---|---|---|

| Normal operation (T < 300°F) | > 0 | Gas cools on expansion |

| Above inversion temp (~800°F+) | < 0 | Gas heats on expansion |

| Ideal gas | = 0 | No temperature change |

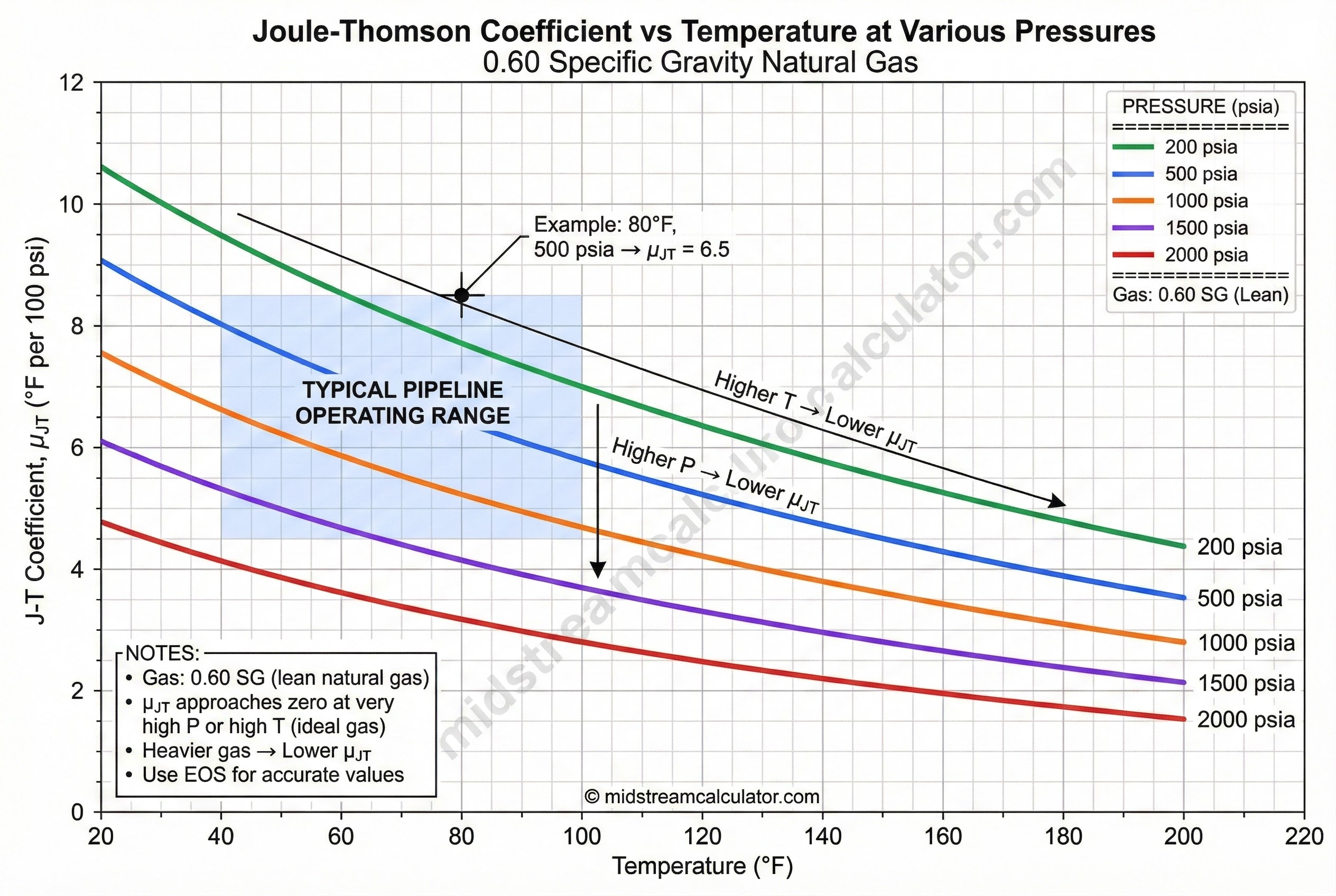

2. J-T Coefficients

Coefficient varies with gas composition, temperature, and pressure. Heavier gas = lower μ_JT = less cooling.

Coefficient by Gas Type

| Gas Type | SG | μ_JT (°F/100 psi) | ΔT for 500 psi drop |

|---|---|---|---|

| Pure Methane | 0.55 | 6.5–7.0 | 32–35°F |

| Lean Gas | 0.60 | 6–8 | 30–40°F |

| Medium Gas | 0.70 | 5–7 | 25–35°F |

| Rich Gas | 0.80 | 4–6 | 20–30°F |

| Very Rich / NGL | 0.90+ | 3–5 | 15–25°F |

Conditions: ~80°F, 500-1000 psia. Use EOS for accurate values.

Rigorous Calculation Method

The calculator uses peer-reviewed correlations for professional-grade accuracy:

| Parameter | Method | Reference |

|---|---|---|

| Pseudo-critical properties | T_pc = 170.5 + 307.3×SG P_pc = 709.6 - 58.7×SG |

Sutton (1985) SPE 14265 |

| J-T coefficient | f(P_r,T_r) × (T_pc/P_pc) × (1/C_p) | ACS Omega (2021) |

| Hydrate temperature | Katz + Towler-Mokhatab averaged | Katz (1945), Towler (2005) |

| Large pressure drops | Step-wise integration (ΔP > 150 psi) | Accounts for varying μ_JT |

Accuracy: J-T coefficient ±5-10%, Hydrate temperature ±2-4°F for SG 0.55-0.90, P 100-2000 psia. For critical/safety applications, verify with process simulator (HYSYS, ProMax) using rigorous EOS.

Example Calculation

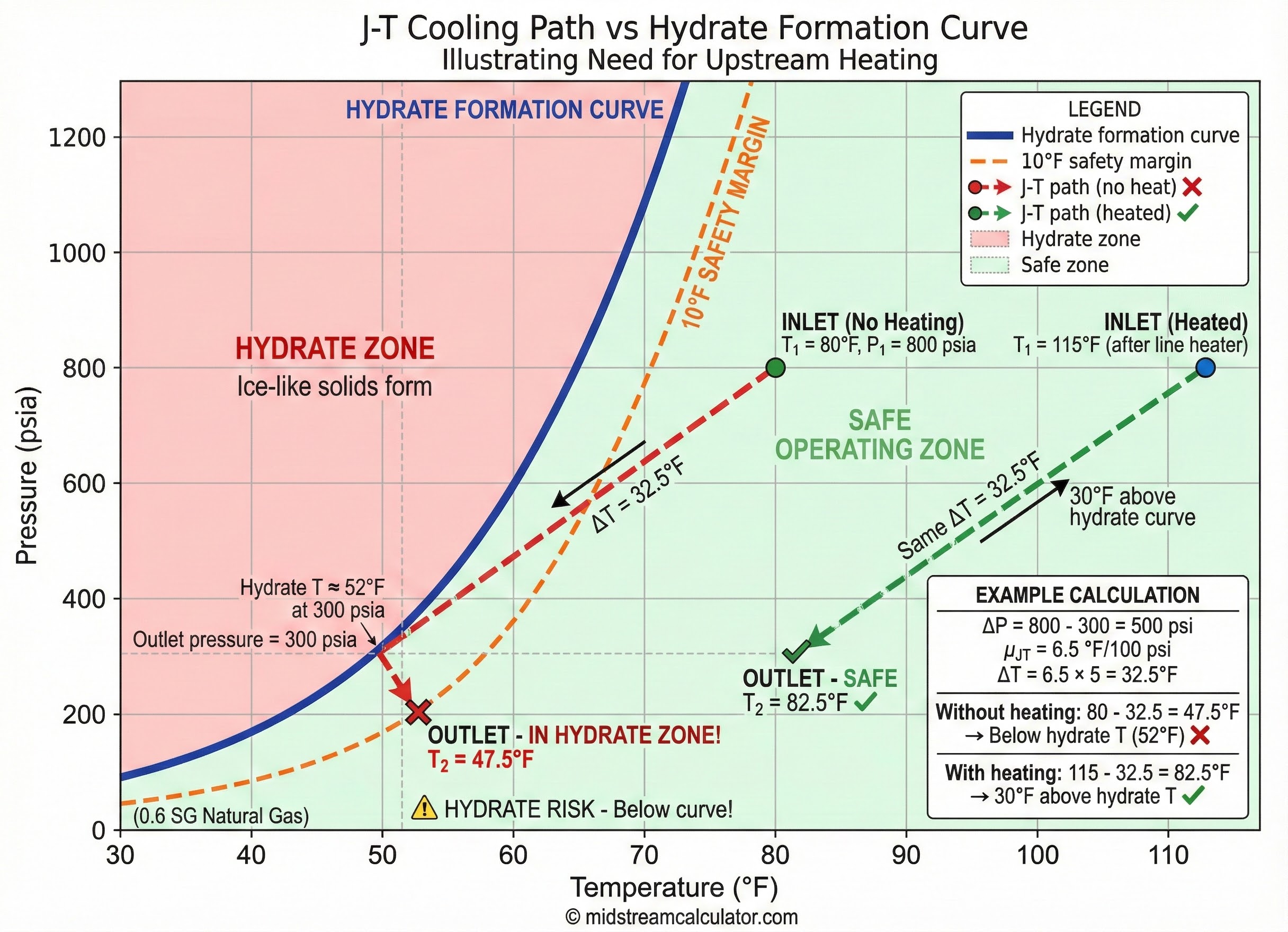

3. Hydrate Risk Assessment

J-T cooling often drops gas temperature into hydrate formation zone. Always check outlet temperature against hydrate curve.

Hydrate Temperature Correlations

The calculator uses two validated correlations, averaged for best accuracy:

Validation Points

| Pressure (psia) | SG | Katz | Towler-M | GPSA Chart |

|---|---|---|---|---|

| 400 | 0.65 | 50.0°F | 49.9°F | 50-54°F |

| 1000 | 0.65 | 62.0°F | 62.9°F | 60-64°F |

| 1000 | 0.70 | 64.0°F | 64.4°F | 62-66°F |

Prevention Methods

| Method | Application | Notes |

|---|---|---|

| Dehydration | Plants, pipelines | <7 lb/MMSCF (glycol); <1 ppm (mol sieve for cryo) |

| Upstream heating | Pressure letdown | Line heater before valve |

| Methanol injection | Wellheads, intermittent | 20-50 wt% in water; high vapor losses |

| MEG injection | Subsea, continuous | 50-80 wt%; regenerable |

| LDHI | Subsea tiebacks | Kinetic/AA; 0.5-2 wt% |

⚠ Design rule: Outlet temperature must be ≥10°F above hydrate formation temperature at outlet pressure. If not, apply mitigation.

4. Applications & Design

Common Applications

| Application | Typical ΔP | ΔT (approx) | Mitigation |

|---|---|---|---|

| NGL plant inlet | 200-400 psi | 15-30°F | Gas/gas exchanger pre-cool |

| Wellhead choke | 1000-3000 psi | 60-200°F | Multi-stage, heating, MeOH |

| Pipeline letdown | 400-800 psi | 25-50°F | Line heater, dehydration |

| Fuel gas regulation | 100-300 psi | 8-20°F | Often none if dehydrated |

Design Procedure

- Get μ_JT from composition, T₁, P₁ (use EOS or chart)

- Calculate ΔT = μ_JT × ΔP (integrate for large ΔP)

- Determine T₂ = T₁ - ΔT

- Compare T₂ to hydrate curve at P₂

- Apply mitigation if margin < 10°F

Common Errors

- Constant μ_JT: Coefficient varies with T and P. Integrate for ΔP > 300 psi.

- "Dry" gas assumption: Gas at 7 lb/MMSCF still forms hydrates if cooled below dew point.

- Ignoring ambient losses: Exposed piping adds cooling beyond J-T effect.

- Material limits: A106-B steel limited to -20°F; use impact-tested steel below.

References

- Sutton, R.P. (1985). "Compressibility Factors for High-Molecular-Weight Reservoir Gases." SPE 14265.

- ACS Omega (2021). "Influences of Hydrogen Blending on the Joule-Thomson Coefficient of Natural Gas." doi:10.1021/acsomega.1c00248

- Katz, D.L. (1945). "Prediction of Conditions for Hydrate Formation in Natural Gases." Trans. AIME, 160, 140-149.

- Towler, B. & Mokhatab, S. (2005). "Quickly Estimate Hydrate Formation Conditions in Natural Gases." Hydrocarbon Processing, 84:61-62.

- GPSA, Sections 13 & 20

- Campbell Gas Conditioning and Processing, Vol. 2

Ready to use the calculator?

→ Launch Calculator