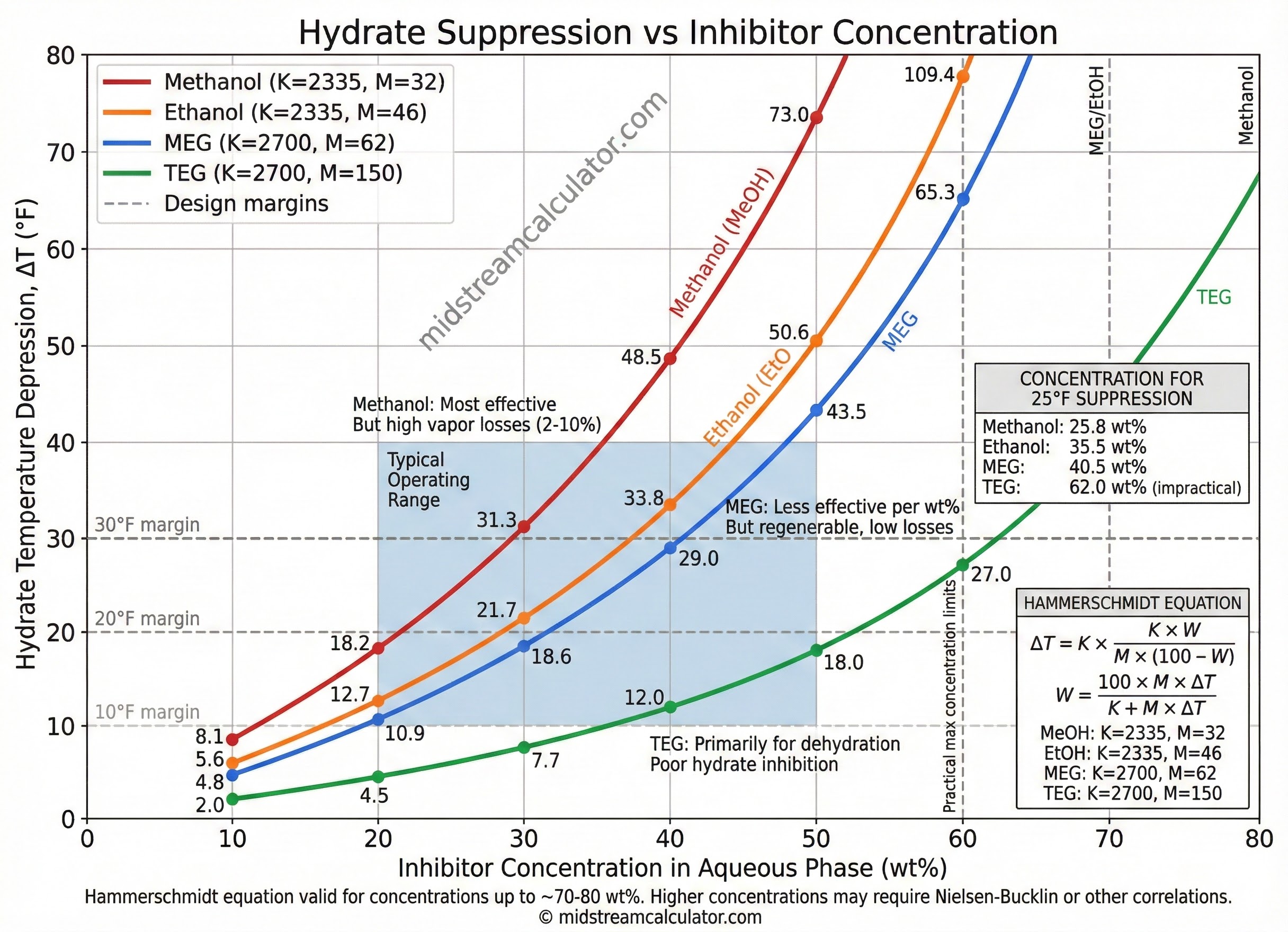

1. Hammerschmidt Equation

Predicts hydrate temperature depression based on inhibitor concentration in the aqueous phase.

Hammerschmidt Equation:

ΔT = K × W / (M × (100 - W))

Solved for concentration:

W = 100 × M × ΔT / (K + M × ΔT)

Where:

ΔT = Hydrate temperature depression (°F)

K = 2,335 (universal Hammerschmidt constant, °F form)

W = Weight % inhibitor in aqueous phase (0-100)

M = Molecular weight of inhibitor (g/mol)

Inhibitor Constants

| Inhibitor | MW | K | Max W | ΔT @ 25 wt% |

|---|---|---|---|---|

| Methanol | 32.04 | 2,335 | ~80% | 24.3°F |

| Ethanol | 46.07 | 2,335 | ~70% | 16.9°F |

| MEG | 62.07 | 2,335 | ~70% | 12.5°F |

| DEG | 106.12 | 2,335 | ~65% | 7.3°F |

| TEG | 150.17 | 2,335 | ~60% | 5.2°F |

Example: Methanol Concentration

Given: Need 30°F hydrate suppression using methanol

K = 2,335, M = 32.04

W = 100 × 32.04 × 30 / (2,335 + 32.04 × 30)

= 96,120 / 3,296

= 29.2 wt% methanol in aqueous phase

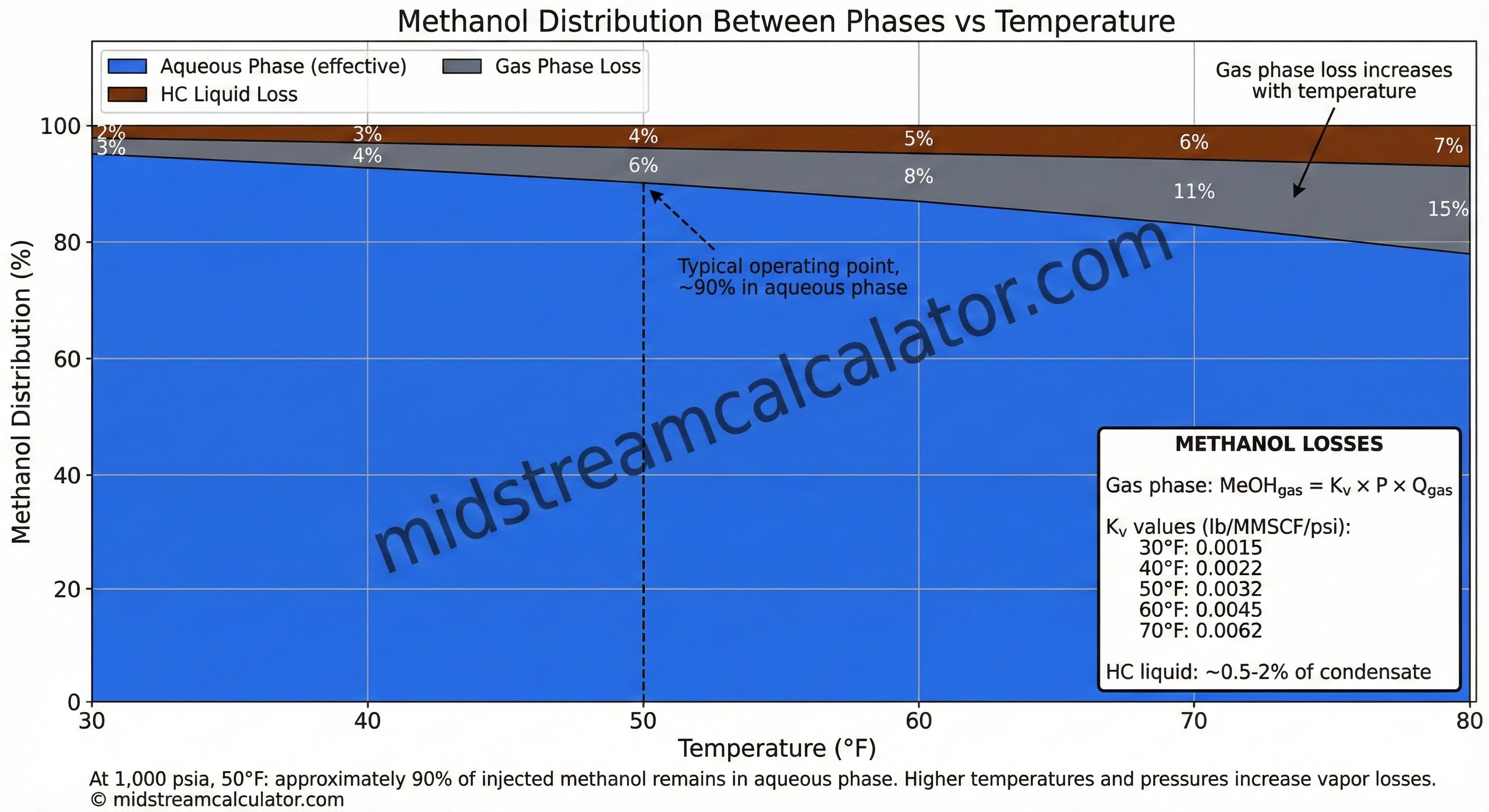

2. Methanol Injection

Methanol is effective but lost to both gas and liquid hydrocarbon phases. Total requirement = aqueous + gas losses + HC losses.

Total methanol requirement:

MeOH_total = MeOH_water + MeOH_gas + MeOH_HC

In aqueous phase (Hammerschmidt):

MeOH_water = W × W_rate / (100 - W) [lb/day]

Lost to gas phase:

MeOH_gas = Kᵥ × P × Q_gas [lb/day]

Where Kᵥ = vapor distribution factor (see table)

Lost to hydrocarbon liquid:

MeOH_HC ≈ 0.5-2% of condensate volume

Methanol Vapor Loss Factor (Kᵥ)

| T (°F) | 30 | 40 | 50 | 60 | 70 |

|---|---|---|---|---|---|

| Kᵥ (lb/MMSCF/psi) | 0.0015 | 0.0022 | 0.0032 | 0.0045 | 0.0062 |

Example: Methanol Injection Rate

Given: 10 MMSCFD, 50 bbl/day water, 1000 psia, 40°F

Need 25 wt% MeOH in water

Water mass: 50 bbl × 350 lb/bbl = 17,500 lb/day

MeOH in water:

= 0.25 × 17,500 / (1 - 0.25) = 5,833 lb/day

MeOH to gas (Kᵥ = 0.0022 at 40°F):

= 0.0022 × 1000 × 10 = 22 lb/day

Total: 5,855 lb/day ÷ 6.6 lb/gal = 887 gal/day (21 bbl/day)

⚠ Safety: Methanol is toxic and flammable. Follow applicable handling codes.

3. Glycol (MEG) Injection

Glycols are preferred for pipelines because they're regenerable with minimal vapor losses.

MEG vs Methanol

| Factor | Methanol | MEG |

|---|---|---|

| Effectiveness (ΔT per wt%) | Higher | Lower |

| Recovery | Usually lost | Regenerated (80-90%) |

| Vapor loss | 2-10% | <0.1% |

| HC solubility loss | 1-2% | <0.5% |

| Cost driver | Operating (makeup) | Capital (regen unit) |

| Best application | Short-term, remote | Long pipelines, offshore |

Glycol Injection Calculation

Lean glycol injection rate:

G_lean = W_water × C_rich / (C_lean - C_rich)

Rich glycol concentration:

C_rich = 100 × M × ΔT / (2,335 + M × ΔT) [from Hammerschmidt]

Where:

G_lean = Lean glycol rate (lb/day)

W_water = Water production (lb/day)

C_lean = Lean glycol concentration (typically 80-90 wt%)

C_rich = Rich glycol concentration (from required ΔT)

K = 2,335 (universal constant, °F)

Example: MEG Injection Rate

Given: 100 bbl/day water, need 25°F suppression

Lean MEG = 85 wt%, M = 62.07, K = 2,335

Rich MEG concentration (Hammerschmidt):

C_rich = 100 × 62.07 × 25 / (2,335 + 62.07 × 25)

= 155,175 / 3,887 = 39.9 wt%

Water mass: 100 bbl × 350 lb/bbl = 35,000 lb/day

Lean MEG rate:

G_lean = 35,000 × 39.9 / (85 - 39.9)

= 1,396,500 / 45.1 = 30,965 lb/day

Volume: 30,965 lb ÷ 9.3 lb/gal = 3,330 gal/day (79 bbl/day)

4. Corrosion Inhibitors

Film-forming corrosion inhibitors protect against CO₂ and H₂S attack. Dosing is typically ppm-based on produced water volume.

Dosing Rates

| Application | Typical Rate (ppm) |

|---|---|

| Sweet gas (CO₂ only) | 10-25 |

| Sour gas (H₂S present) | 25-50 |

| High CO₂ (>5 mol%) | 50-100 |

| Produced water systems | 25-75 |

Injection Rate Calculation

Continuous injection:

Rate (gal/day) = Q_water (bbl/day) × ppm × 42 / (ρ × 10⁶)

Where:

Q_water = Water production rate (bbl/day)

ppm = Target concentration

ρ = Inhibitor density (lb/gal), typically 8-9

42 = gal/bbl

Example:

500 bbl/day water, 50 ppm, ρ = 8.5 lb/gal

Rate = 500 × 50 × 42 / (8.5 × 10⁶) = 0.12 gal/day

References

- GPSA, Section 20

- NACE SP0106 – Internal Corrosion Control

- API RP 14E – Offshore Platform Piping

Ready to use the calculator?

→ Launch Calculator