1. Overview & Unit Systems

Hydrogen sulfide (H2S) is a highly toxic, flammable gas commonly encountered in oil and gas production. Accurate concentration conversions are critical for safety, regulatory compliance, and materials selection.

ppm (parts per million)

Volume basis

Most common for gas analysis and safety monitoring (ppmv by volume).

mol% (mole percent)

Molar basis

Used in process design, phase equilibrium, and gas composition reports.

mg/m³ (milligrams per cubic meter)

Mass concentration

OSHA/NIOSH exposure limits specified as mass per volume at standard conditions.

grains/100 scf

Traditional oil field unit

Legacy unit still used in pipeline gas specs and sulfur removal equipment.

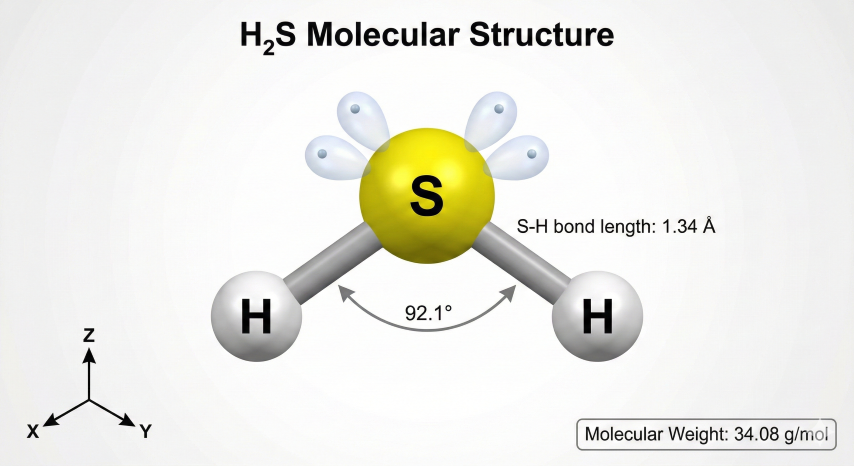

Key Properties of H2S

| Property | Value | Units |

|---|---|---|

| Molecular weight | 34.08 | g/mol |

| Boiling point | -76°F (-60°C) | at 1 atm |

| Specific gravity (air = 1) | 1.176 | dimensionless |

| Lower explosive limit (LEL) | 4.3% | vol% in air |

| Upper explosive limit (UEL) | 45.5% | vol% in air |

| Odor threshold | 0.01–0.3 ppm | rotten egg smell |

| Olfactory fatigue threshold | 100–150 ppm | sense of smell paralyzed |

Standard Conditions for Conversions

- Temperature: 60°F (15.6°C) or 25°C depending on standard used

- Pressure: 14.696 psia (101.325 kPa) - standard atmosphere

- Molar volume at STP: 379.5 scf/lbmol (22.414 L/mol at 0°C, 1 atm)

- Molar volume at 60°F: 379.49 scf/lbmol (US oil/gas standard)

2. Conversion Equations

All conversions assume ideal gas behavior, which is accurate for H2S at atmospheric pressure and ambient temperature.

ppm to mol%

ppm to mg/m³

ppm to grains/100 scf

mol% to grains/100 scf

Conversion Table (GPSA Standard Conditions)

| ppm | mol% | mg/m³ (60°F) | grains/100 scf | lb/MMscf | Classification |

|---|---|---|---|---|---|

| 4 | 0.0004 | 5.8 | 0.25 | 0.36 | Sour gas / Pipeline spec |

| 10 | 0.001 | 14.4 | 0.63 | 0.90 | OSHA 8-hr TWA limit |

| 20 | 0.002 | 28.8 | 1.26 | 1.80 | OSHA ceiling (15 min) |

| 100 | 0.01 | 144 | 6.29 | 8.98 | NIOSH IDLH |

| 500 | 0.05 | 720 | 31.4 | 44.9 | Knockdown level |

| 1,000 | 0.1 | 1,439 | 62.9 | 89.8 | Typical amine feed |

| 5,000 | 0.5 | 7,195 | 314 | 449 | High sour gas plant feed |

| 10,000 | 1.0 | 14,390 | 629 | 898 | Very sour (Permian Basin) |

| 50,000 | 5.0 | 71,950 | 3,143 | 4,490 | Extreme sour (acid gas) |

Table values calculated using GPSA formulas: grains/100scf = ppm × 0.06286; lb/MMscf = ppm × 0.0898; mg/m³ = ppm × 1.439 at 60°F

Temperature Correction for mg/m³

When converting at non-standard temperatures:

3. Toxicity Levels & Exposure Limits

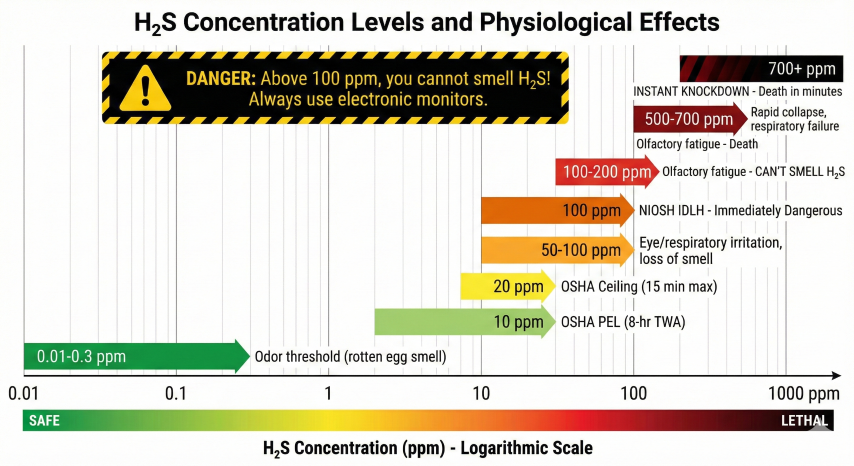

H2S is immediately dangerous to life and health (IDLH) at concentrations as low as 100 ppm. Understanding exposure limits and physiological effects is critical for safety.

OSHA Regulatory Limits (29 CFR 1910.1000)

| Limit Type | Concentration | Duration | Regulation |

|---|---|---|---|

| PEL (8-hr TWA) | 10 ppm (14 mg/m³) | 8-hour time-weighted average | 1910.1000 Table Z-2 |

| Ceiling limit | 20 ppm (28 mg/m³) | Maximum 15 minutes | Never exceed |

| Action level | 5 ppm | 8-hour TWA | Triggers monitoring requirements |

NIOSH Exposure Limits

| Limit Type | Concentration | Definition |

|---|---|---|

| REL (10-min ceiling) | 10 ppm (15 mg/m³) | Recommended exposure limit |

| IDLH | 100 ppm (140 mg/m³) | Immediately dangerous to life/health |

| SCBA required | ≥ 100 ppm | Self-contained breathing apparatus mandatory |

Physiological Effects by Concentration

| Concentration (ppm) | Duration | Physiological Effect |

|---|---|---|

| 0.01–0.3 | - | Odor threshold (rotten eggs); detectable by smell |

| 10 | 8 hours | OSHA permissible exposure limit; mild eye irritation |

| 20–50 | 1+ hours | Eye irritation, headache, nausea, sore throat |

| 50–100 | 30–60 min | Severe eye/respiratory irritation, coughing, loss of smell |

| 100–200 | 2–15 min | Olfactory fatigue (can't smell H2S), severe respiratory distress |

| 200–500 | Minutes | Pulmonary edema, unconsciousness, possible death |

| 500–700 | Minutes | Collapse, respiratory arrest, high fatality risk |

| 700+ | Seconds | Immediate collapse, respiratory paralysis, death ("knockdown") |

H2S Monitoring Requirements

- Confined spaces: Continuous monitoring required when H2S may be present (> 4 ppm possible)

- Personal monitors: Workers in sour gas areas must wear calibrated personal H2S detectors

- Alarm setpoints: Low alarm 10 ppm, high alarm 15–20 ppm, evacuation 20–25 ppm

- Calibration: Daily bump test, monthly full calibration with certified gas

- Fixed monitors: Area monitors at potential leak points (wellheads, compressors, amine units)

- Wind socks: Visual wind direction indicators for evacuation planning

Emergency Response Procedures

- Evacuation: Move upwind or crosswind immediately when alarm sounds (H2S is heavier than air)

- SCBA required: Only trained personnel with SCBA may enter areas > 100 ppm

- Victim rescue: Never attempt rescue without SCBA and backup team

- First aid: Move victim to fresh air immediately; administer oxygen if trained; CPR if not breathing

- Medical attention: All H2S exposures > 20 ppm require medical evaluation (delayed pulmonary edema risk)

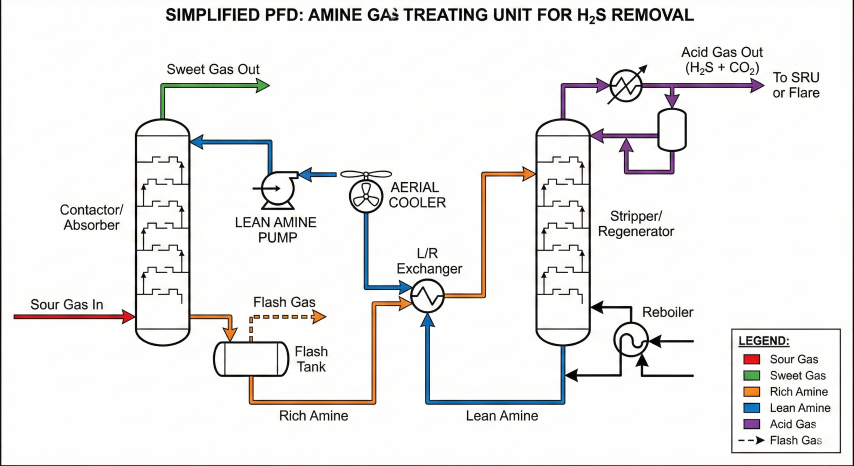

4. Sour Gas Classification & Pipeline Specifications

The presence of H2S triggers specific regulatory requirements, material selection criteria, and operational procedures.

Sour Gas Definition

Total Sulfur Specifications

Pipeline gas specifications often limit both H2S and total sulfur content:

| Component | Typical Limit | Basis |

|---|---|---|

| H2S (hydrogen sulfide) | 0.25 grains/100 scf (195 ppm) | Corrosion, toxicity |

| Total sulfur | 5 grains/100 scf (20 ppm S) | SO2 emissions when burned |

| Mercaptans (RSH) | Included in total sulfur | Odor, corrosion |

| Carbonyl sulfide (COS) | Included in total sulfur | LNG processing issues |

Common Pipeline Specifications

| Pipeline System | H2S Limit | Total Sulfur Limit |

|---|---|---|

| Interstate transmission | 0.25–0.5 grains/100 scf | 5 grains/100 scf |

| Distribution (utility) | 0.25 grains/100 scf | 5 grains/100 scf |

| LNG plants | < 4 ppm | < 1 ppm total S |

| Gas processing plants | Varies (sweet outlet) | 2–5 grains/100 scf outlet |

Conversion Example: Pipeline Spec Verification

Regulatory Drivers for H2S Limits

- 29 CFR 1910.1000: OSHA workplace exposure limits (10 ppm TWA, 20 ppm ceiling)

- 49 CFR Part 192: Federal pipeline safety standards (state-specific sour gas rules)

- EPA Clean Air Act: SO₂ emissions limits from gas combustion (drives total sulfur specs)

- State regulations: Texas RRC, California DOGGR have specific sour gas well requirements

- NACE MR0175/ISO 15156: Material selection for sour service (≥ 4 ppm H2S)

5. NACE MR0175/ISO 15156 Material Requirements

NACE MR0175 (now ISO 15156) specifies material requirements for equipment used in H2S-containing environments. Compliance is mandatory for sour gas service (H2S ≥ 4 ppm).

Sour Service Classification

Carbon Steel Requirements (NACE MR0175 Part 2)

| Material Type | Hardness Limit | Additional Requirements |

|---|---|---|

| Carbon & low-alloy steels | ≤ 22 HRC (237 HBW) | All product forms |

| Welds (base metal ≤ 22 HRC) | ≤ 22 HRC in HAZ | PWHT often required |

| Cold-worked components | ≤ 22 HRC after cold work | Stress relief may be needed |

| Fasteners (bolts/studs) | ≤ 22 HRC | Special sour service bolting required |

Stainless Steel Requirements (NACE MR0175 Part 3)

| Alloy Type | Hardness Limit | Chloride Consideration |

|---|---|---|

| Austenitic (e.g., 316, 316L) | ≤ 22 HRC (237 HBW) | SCC risk if Cl⁻ > 50 ppm |

| Duplex (e.g., 2205, 2507) | ≤ 30 HRC (varies by grade) | Good H2S and Cl⁻ resistance |

| Super austenitic (6Mo) | ≤ 22 HRC | Excellent corrosion resistance |

| Martensitic (410, 13Cr) | ≤ 22 HRC | Limited H2S resistance |

Corrosion-Resistant Alloys (CRAs) for Severe Sour Service

| Alloy | H2S Service Limit | Applications |

|---|---|---|

| Alloy 625 (UNS N06625) | No limit (per MR0175) | Valves, tubing, high H2S wells |

| Alloy 825 (UNS N08825) | No limit | Heat exchangers, piping |

| Duplex 2205 (UNS S32205) | < 25% H2S (environment-dependent) | Piping, pressure vessels |

| Super duplex 2507 | Moderate H2S + high Cl⁻ | Offshore, high chloride environments |

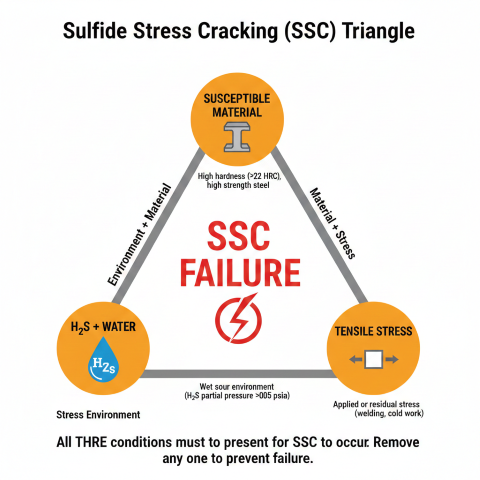

Sulfide Stress Cracking (SSC) Mechanisms

SSC is the primary failure mode in sour service. It occurs when three conditions coincide:

- Susceptible material: High-strength steel (hardness > 22 HRC)

- H2S environment: Wet H2S present (even trace amounts with water)

- Tensile stress: Applied or residual stress (e.g., from welding, cold work)

SSC Prevention Strategies

Example: Material Selection for Sour Gas Valve

Post-Weld Heat Treatment (PWHT) Requirements

- Purpose: Reduce HAZ (heat-affected zone) hardness to ≤ 22 HRC and relieve residual stresses

- When required: All carbon/low-alloy steel welds in sour service unless qualified by testing

- Temperature: 1100–1200°F (593–649°C) for carbon steel

- Hold time: 1 hour per inch of thickness (minimum 1 hour)

- Verification: Hardness survey of weld and HAZ after PWHT (≤ 22 HRC required)

Ready to use the calculator?

→ Launch Calculator