1. Flow Regimes

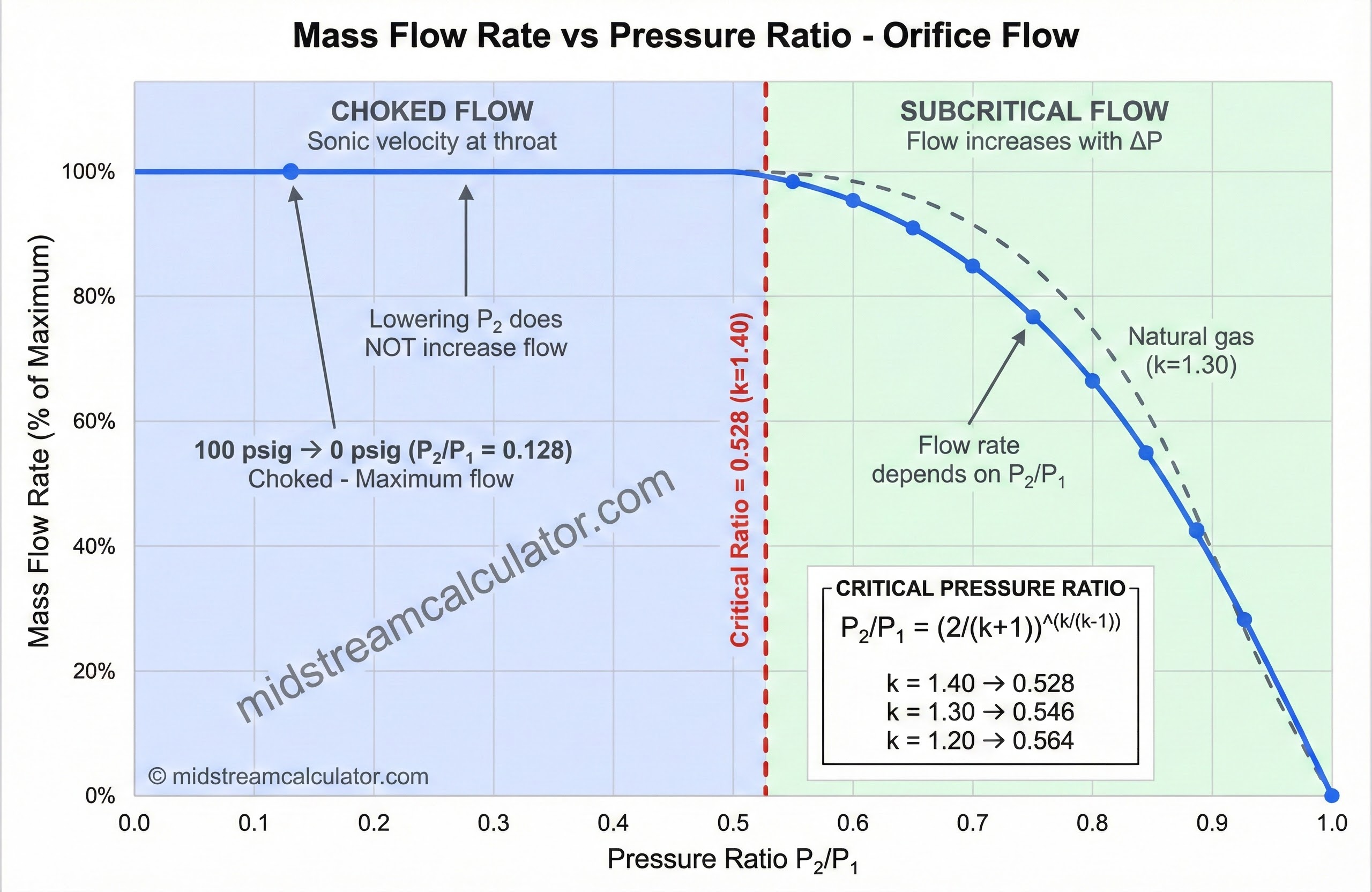

Gas flow through an orifice is either subcritical (downstream pressure affects flow) or critical/choked (flow limited by sonic velocity).

Critical Ratios by Gas

| Gas | k (Cp/Cv) | Critical Ratio | Y (choked) |

|---|---|---|---|

| Air, N₂, O₂ | 1.40 | 0.528 | 0.667 |

| Hydrogen | 1.41 | 0.527 | 0.669 |

| Methane | 1.31 | 0.545 | 0.651 |

| Natural Gas | 1.27–1.32 | 0.544–0.552 | 0.645–0.655 |

| CO₂ | 1.30 | 0.546 | 0.649 |

| H₂S | 1.32 | 0.544 | 0.653 |

| Steam | 1.33 | 0.543 | 0.655 |

| Propane | 1.13 | 0.575 | 0.615 |

Practical rule: Most blowdowns to atmosphere are choked. A 100 psig vessel venting to 0 psig has P₂/P₁ = 14.7/114.7 = 0.13, well below the critical ratio.

2. Design Equations

Gas Service — Choked Flow

Gas Service — Subcritical Flow

Liquid Service

Blowdown Time

3. Coefficients & Reference Data

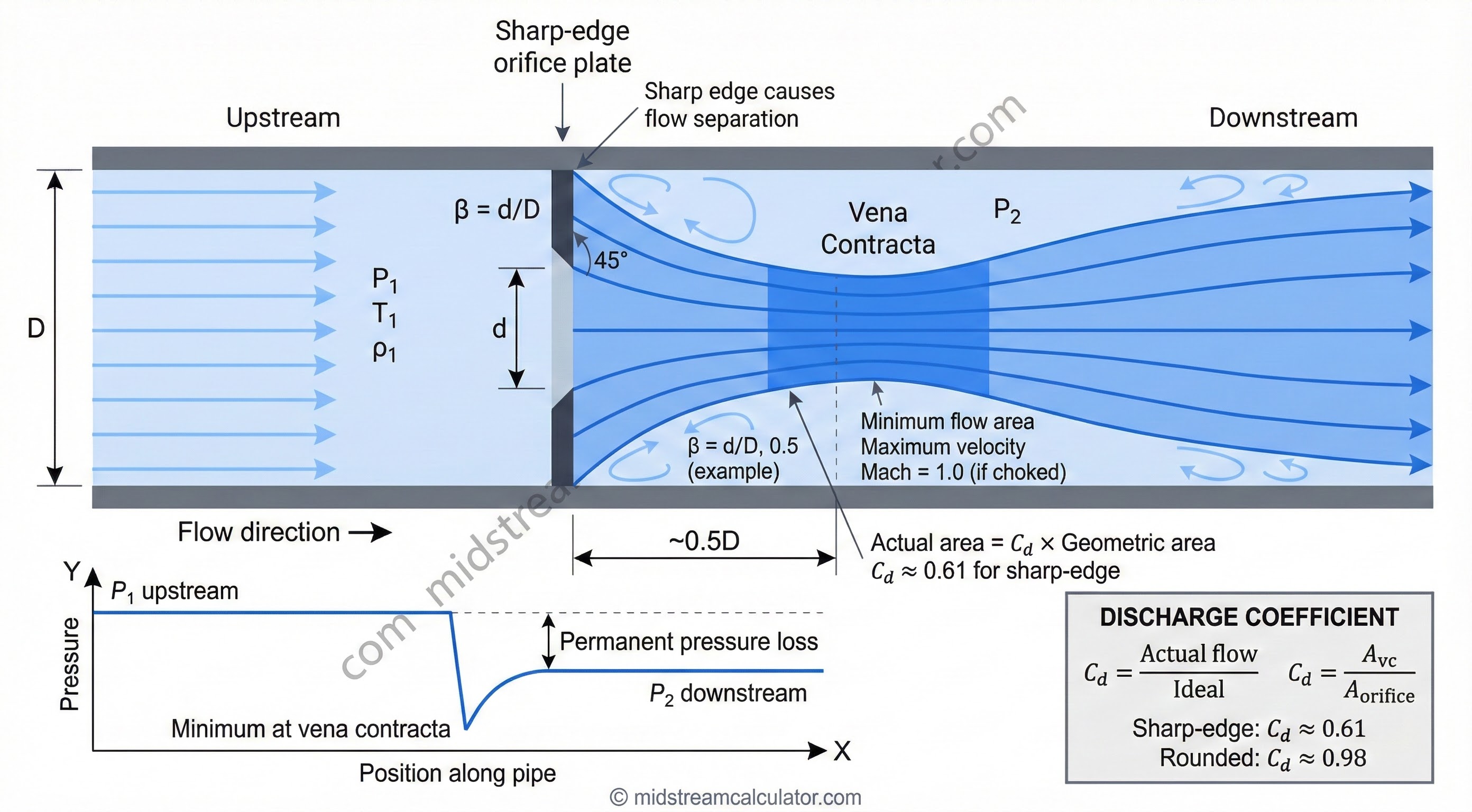

Discharge Coefficients

| Orifice Type | Cd | Application |

|---|---|---|

| Sharp-edge, corner taps | 0.61 | Standard drain orifice |

| Sharp-edge, flange taps | 0.60 | Metering orifice |

| Square-edge entrance | 0.82 | Pipe entrance |

| Rounded entrance (r/d>0.1) | 0.98 | Low-loss nozzle |

| Venturi / flow nozzle | 0.99 | Metering |

Typical Orifice Sizes

| Application | Typical Size | Design Consideration |

|---|---|---|

| Separator blowdown | 1" – 2" | Choked flow, noise |

| Pipeline blowdown | 0.5" – 1.5" | Line pack volume |

| Compressor scrubber | 0.75" – 1.5" | Auto-drain cycle |

| Tank drain (liquid) | 2" – 4" | Gravity flow |

Standard Orifice Sizes

| Diameter (in) | Area (in²) | Diameter (in) | Area (in²) |

|---|---|---|---|

| 0.250 | 0.0491 | 0.875 | 0.601 |

| 0.375 | 0.110 | 1.000 | 0.785 |

| 0.500 | 0.196 | 1.250 | 1.227 |

| 0.625 | 0.307 | 1.500 | 1.767 |

| 0.750 | 0.442 | 2.000 | 3.142 |

Expansion Factor Y (Choked Flow)

Use this table to find Y for choked flow based on gas specific heat ratio k.

| k (Cp/Cv) | Critical Ratio | Y (choked) | Typical Gas |

|---|---|---|---|

| 1.10 | 0.585 | 0.600 | Heavy hydrocarbons |

| 1.15 | 0.573 | 0.615 | Propane |

| 1.20 | 0.564 | 0.629 | Rich natural gas |

| 1.25 | 0.555 | 0.640 | — |

| 1.30 | 0.546 | 0.649 | Natural gas, CO₂ |

| 1.35 | 0.538 | 0.658 | — |

| 1.40 | 0.528 | 0.667 | Air, N₂, O₂ |

| 1.45 | 0.520 | 0.675 | — |

| 1.66 | 0.487 | 0.725 | Helium, Argon |

Y = √[k × (2/(k+1))^((k+1)/(k-1))]

Critical Flow Properties by Gas

| Gas | MW | k | Critical Ratio | Y |

|---|---|---|---|---|

| Air | 28.97 | 1.40 | 0.528 | 0.667 |

| Nitrogen (N₂) | 28.01 | 1.40 | 0.528 | 0.667 |

| Oxygen (O₂) | 32.00 | 1.40 | 0.528 | 0.667 |

| Methane (CH₄) | 16.04 | 1.31 | 0.545 | 0.651 |

| Natural Gas (0.65 SG) | 18.8 | 1.27–1.32 | 0.544–0.552 | 0.645–0.655 |

| Carbon Dioxide (CO₂) | 44.01 | 1.30 | 0.546 | 0.649 |

| Hydrogen Sulfide (H₂S) | 34.08 | 1.32 | 0.544 | 0.653 |

| Hydrogen (H₂) | 2.02 | 1.41 | 0.527 | 0.669 |

| Propane (C₃H₈) | 44.10 | 1.13 | 0.575 | 0.615 |

| Steam | 18.02 | 1.33 | 0.543 | 0.655 |

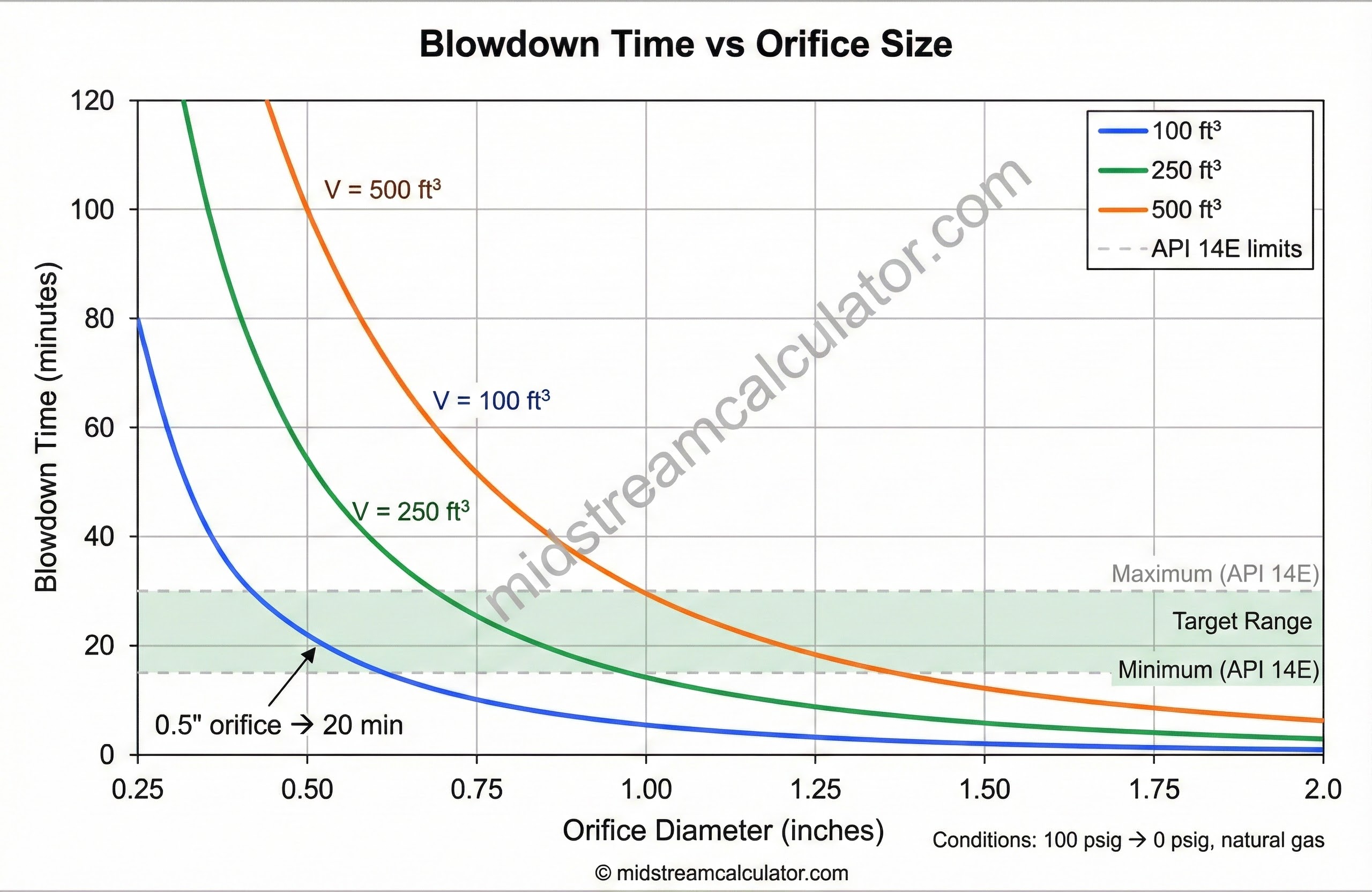

Quick Sizing Reference

Approximate blowdown times for natural gas (0.65 SG) from 100 psig to atmosphere at 80°F.

| Vessel Volume | 0.50" orifice | 0.75" orifice | 1.00" orifice | 1.50" orifice |

|---|---|---|---|---|

| 25 ft³ | 5 min | 2.2 min | 1.3 min | 0.6 min |

| 50 ft³ | 10 min | 4.5 min | 2.5 min | 1.1 min |

| 100 ft³ | 20 min | 9 min | 5 min | 2.2 min |

| 250 ft³ | 50 min | 22 min | 12.5 min | 5.5 min |

| 500 ft³ | 100 min | 45 min | 25 min | 11 min |

| 1000 ft³ | 200 min | 90 min | 50 min | 22 min |

Based on Cd = 0.61, choked flow. Times are approximate—use calculator for accurate sizing.

Blowdown Time Scaling

To adjust quick-sizing values for different conditions:

| Parameter Change | Effect on Time | Example |

|---|---|---|

| Double vessel volume | × 2.0 | 100→200 ft³: 20 min → 40 min |

| Double orifice area | ÷ 2.0 | 0.5"→0.7" (2× area): 20 min → 10 min |

| Double pressure | × 1.4 (approx) | 100→200 psig: 20 min → 28 min |

| Heavier gas (higher MW) | × √(MW₂/MW₁) | NG→Propane: 20 min → 31 min |

| Higher temperature | × √(T₂/T₁) | 80°F→200°F: 20 min → 22 min |

API 14E guidance: Size for 15-30 min blowdown (gas) or 30-60 min (liquid) unless process requirements dictate otherwise.

4. Worked Example

Problem: Size a blowdown orifice for a 100 ft³ separator at 100 psig to depressurize to atmosphere in 20 minutes.

Given

| Volume | V = 100 ft³ |

| Upstream pressure | P₁ = 114.7 psia |

| Downstream pressure | P₂ = 14.7 psia |

| Gas | Natural gas, SG = 0.65, k = 1.30 |

| Temperature | T = 80°F = 540°R |

| Target time | t = 20 min = 1200 s |

Solution

⚠ Notes: This simplified calculation uses average density. For accurate blowdown time, integrate over the pressure decay curve. Add 10-20% margin for fouling.

References

- API RP 14E – Offshore Platform Piping Systems

- ISO 5167-2 – Orifice Plates

- Crane Technical Paper 410

- GPSA, Section 6

Ready to use the calculator?

→ Launch Calculator