1. Process Overview

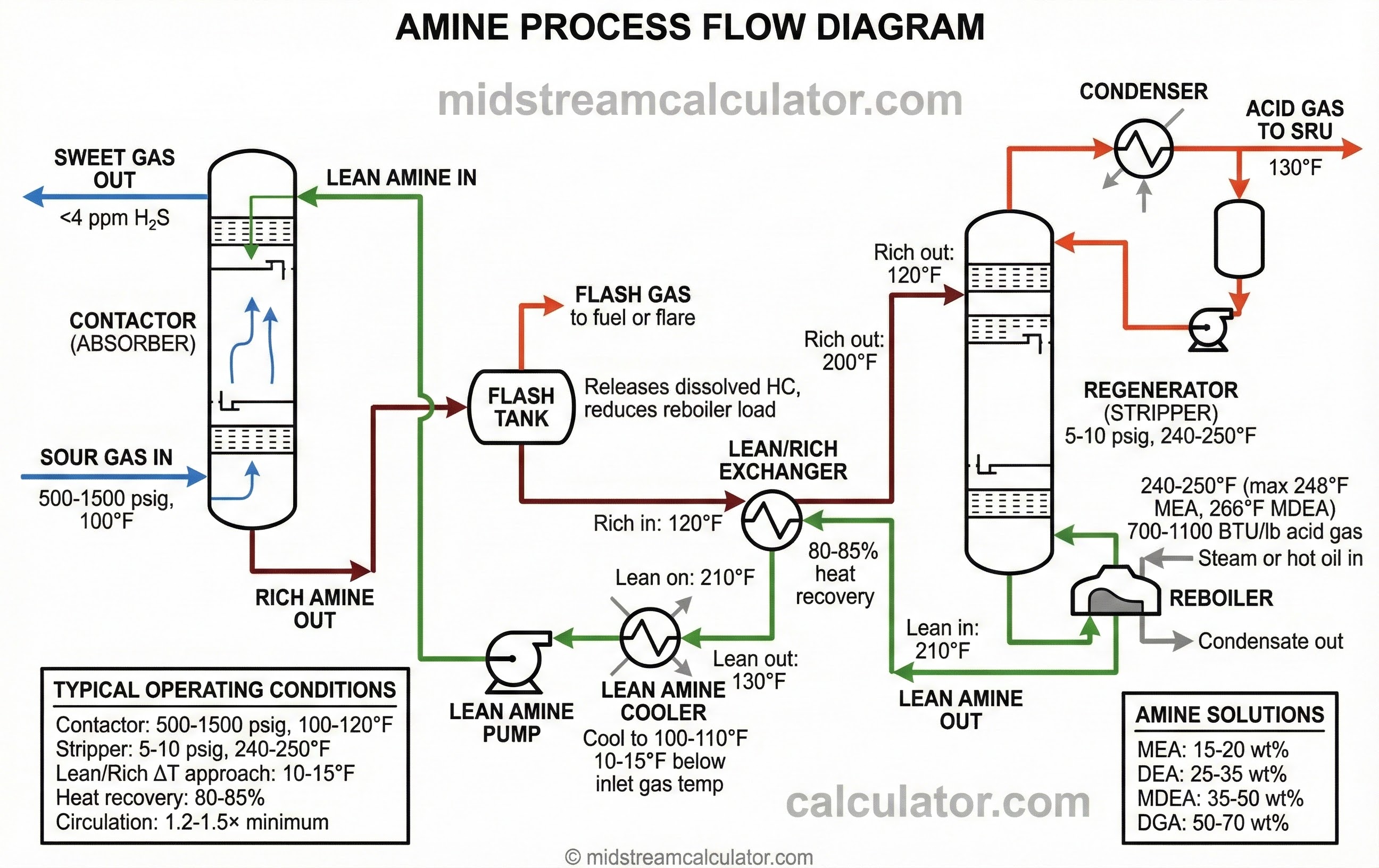

Amine treating absorbs acid gases at high pressure/low temperature, then releases them at low pressure/high temperature. The amine circulates continuously between absorber (contactor) and regenerator (stripper).

Absorption

100-120°F, high P

Exothermic reaction. Favor low T, high P.

Regeneration

240-260°F, ~5 psig

Reverse reaction. Heat drives off acid gas.

Heat Recovery

80-85%

Lean/rich exchanger critical for economics.

Selectivity

MDEA only

Tertiary amines absorb H₂S 10-20× faster than CO₂.

Reaction Chemistry

| Amine Type | CO₂ Mechanism | Speed | Heat of Reaction |

|---|---|---|---|

| Primary (MEA, DGA) | Carbamate: 2RNH₂ + CO₂ → RNHCOO⁻ + RNH₃⁺ | Fast | ~900 BTU/lb CO₂ |

| Secondary (DEA) | Carbamate (similar to primary) | Moderate | ~800 BTU/lb CO₂ |

| Tertiary (MDEA) | Bicarbonate: R₃N + CO₂ + H₂O → R₃NH⁺ + HCO₃⁻ | Slow | ~700 BTU/lb CO₂ |

H₂S reacts by direct proton transfer (fast for all amines): RₓNH + H₂S → RₓNH₂⁺ + HS⁻

2. Solvent Selection

Amine Comparison

| Property | MEA | DEA | MDEA | DGA |

|---|---|---|---|---|

| Type | Primary | Secondary | Tertiary | Primary |

| Concentration | 15-20% | 25-35% | 35-50% | 50-70% |

| Max Loading (CS) | 0.35 | 0.35 | 0.70-0.80 | 0.35 |

| H₂S Selective? | No | Slight | Yes | No |

| Heat Duty | High | Moderate | Low | Moderate |

| COS/CS₂ Tolerance | Poor | Good | Excellent | Moderate |

| Max Reboiler Temp | 248°F | 248°F | 266°F | 257°F |

| Freezing Point | 50°F | 82°F | -6°F | -18°F |

Selection Guide

MEA

Complete CO₂ removal (<50 ppm). Simple gas. Low partial pressure. Requires reclaimer for COS/CS₂.

DEA

COS/CS₂ in feed. Refinery service. No reclaimer needed. Moderate acid gas loads.

MDEA

Selective H₂S removal. CO₂ slip for Claus enrichment. Lowest energy. High loading capacity.

DGA

Cold climates (<0°F). Offshore platforms. High acid gas pickup per volume. Space-constrained.

3. Loading & Circulation

Loading Definitions

Maximum Loading Limits

| Amine | Carbon Steel | SS316 | Typical Lean |

|---|---|---|---|

| MEA | 0.35 mol/mol | 0.50 | 0.10-0.15 |

| DEA | 0.35 | 0.55 | 0.01-0.05 |

| MDEA | 0.70-0.80 | 0.90+ | 0.004-0.01 |

| DGA | 0.35 | 0.50 | 0.05-0.10 |

⚠ Never exceed loading limits. Overloading causes severe corrosion, equipment pitting, and potential failure. MDEA tolerates higher loading due to weaker CO₂ bond (bicarbonate vs carbamate).

Example: MDEA Circulation

Given: Remove 100 kmol/h acid gas, MDEA 42.5% wt, solution density 1020 kg/m³

4. Regeneration

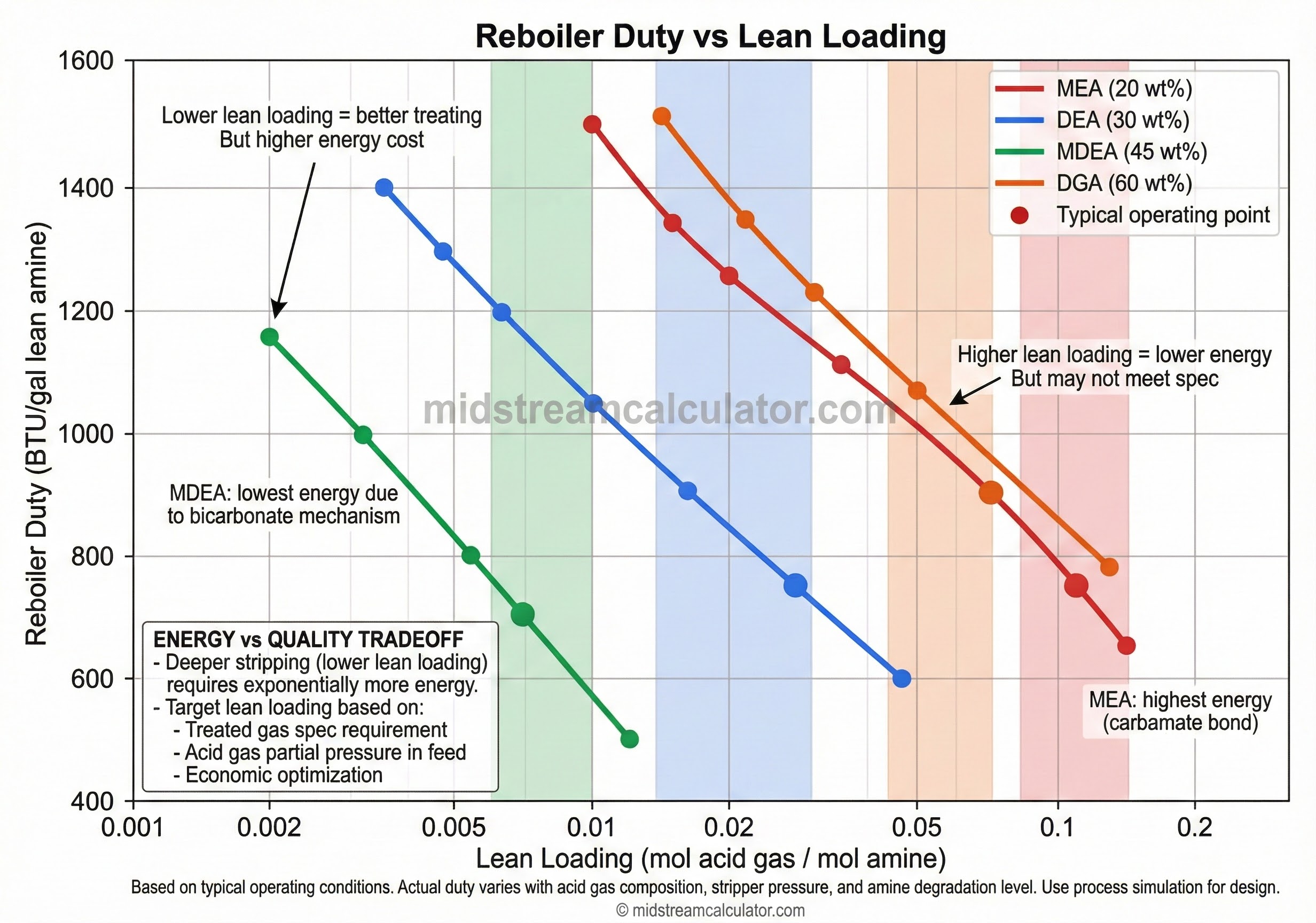

Reboiler duty is 60-80% of operating cost. Four components contribute:

Reaction Heat

40-60%

Reverse absorption. MEA highest, MDEA lowest.

Sensible Heat

20-30%

Heat amine from ~120°F to ~250°F.

Stripping Steam

15-25%

Vapor to carry acid gas. More for lower lean loading.

Reflux

5-15%

Condense water at overhead. Minimize amine loss.

Reboiler Duty by Amine

| Amine | BTU/lb Acid Gas | BTU/gal Lean Amine | Notes |

|---|---|---|---|

| MEA (20%) | 900-1100 | 900-1100 | Highest energy (carbamate bond) |

| DEA (30%) | 800-950 | 850-1000 | Similar chemistry to MEA |

| MDEA (45%) | 700-850 | 700-900 | Lowest (bicarbonate bond) |

| DGA (60%) | 850-1000 | 1100-1300 | High concentration offsets |

Temperature Limits

Exceeding limits causes irreversible thermal degradation:

- MEA/DEA: 248°F (120°C) max — forms formic acid, glycolic acid

- MDEA: 266°F (130°C) max — more stable tertiary structure

- DGA: 257°F (125°C) max

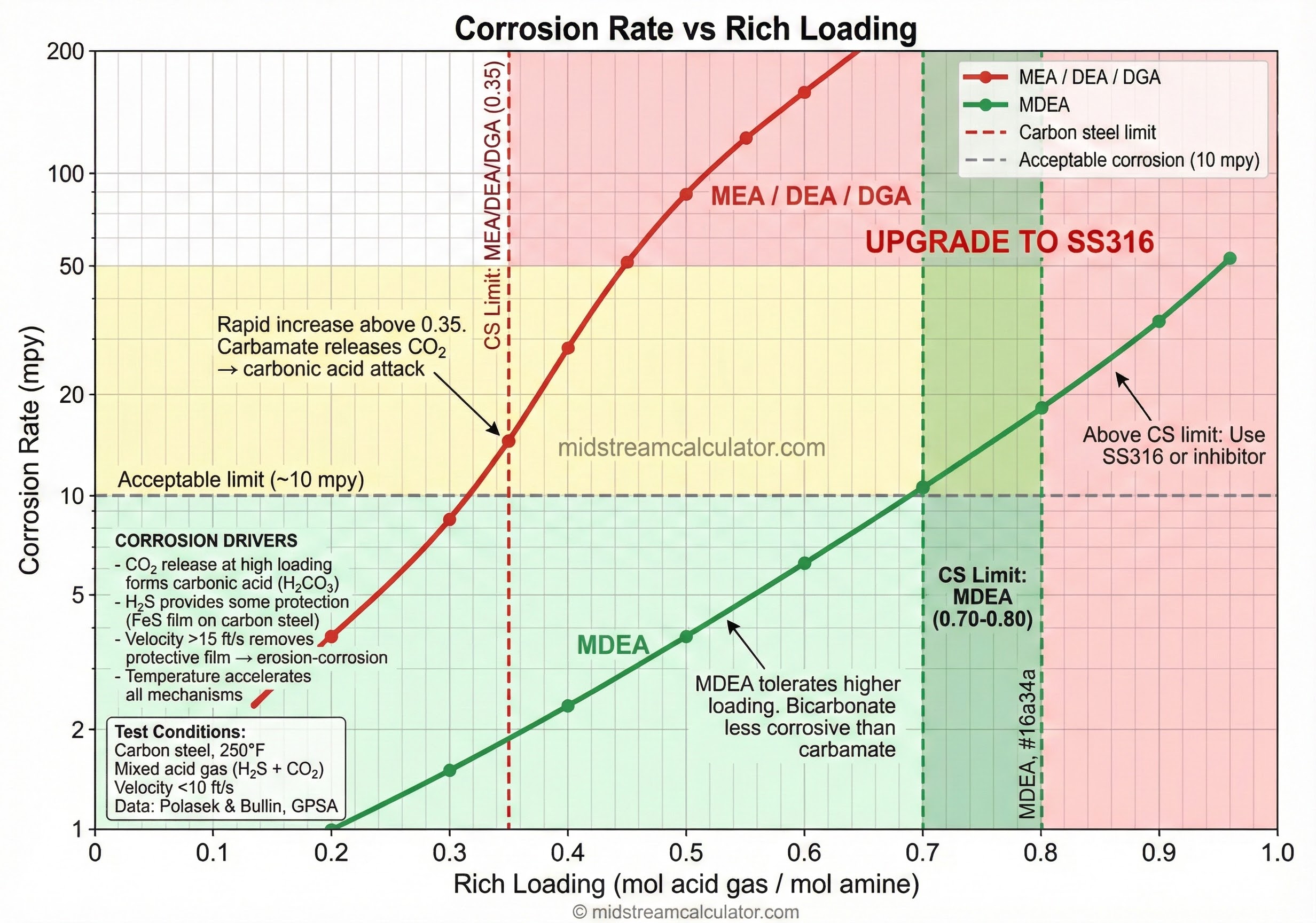

5. Corrosion Limits

Rich amine loading drives corrosion rate. Stay below limits or upgrade metallurgy.

Metallurgy by Loading

| Location | Loading <0.35 | Loading 0.35-0.50 | Loading >0.50 |

|---|---|---|---|

| Contactor | CS | CS + inhibitor | CS, SS internals |

| Rich amine piping | CS (<10 ft/s) | SS316 | SS316 |

| Lean/rich exchanger | CS/CS | SS316/CS | SS316/SS316 |

| Reboiler tubes | CS | SS304 | SS316 |

| Stripper bottom | CS | SS304 clad | SS316 clad |

| Lean amine piping | CS | CS | CS |

Corrosion Mechanisms

Acid Gas Attack

CO₂ forms carbonic acid. Worse above 0.4 loading. Velocity-sensitive.

Heat-Stable Salts

Formate, acetate, oxalate lower pH. Require reclaiming.

Thermal Degradation

High reboiler temp breaks down amine to corrosive acids.

Erosion-Corrosion

Velocity >15 ft/s removes protective FeS film.

⚠ API 945: Amine stress corrosion cracking can occur at loading >0.25 mol/mol with high stress and temperature >200°F. Use PWHT on all rich amine pressure vessels.

6. Design Parameters

Contactor (Absorber)

| Parameter | Range | Notes |

|---|---|---|

| Gas velocity | 1.5-2.5 ft/s | Based on tower cross-section |

| Liquid loading | 20-40 gpm/ft² | Ensures wetting |

| Lean amine temp | 10-15°F below gas | Prevents HC condensation |

| Pressure | 500-1500 psig | Higher P improves absorption |

Regenerator (Stripper)

| Parameter | Range | Notes |

|---|---|---|

| Pressure | 5-10 psig | Lower aids stripping |

| Reboiler temp | 240-250°F | Below degradation limit |

| Reflux ratio | 0.5-1.5 | Minimizes amine loss |

| Lean/rich ΔT approach | 10-15°F | Lower = better recovery |

Troubleshooting

| Problem | Causes | Solutions |

|---|---|---|

| Foaming | Hydrocarbons, solids, degradation | Antifoam 5-25 ppm, filter, flash tank |

| High lean loading | Low reboiler duty, HSS, degraded amine | Increase duty, reclaim, replace |

| Acid gas breakthrough | Under-circulation, poor contacting | Increase flow, check trays/packing |

| High corrosion | Overloading, HSS, O₂ ingress | Reduce loading, reclaim, N₂ blanket |

References

- GPSA, Sections 20-21

- API 945 – Avoiding Environmental Cracking in Amine Units

- Kohl & Nielsen – Gas Purification, 5th Edition

- Bryan Research (Polasek & Bullin) – Amine Treating

Ready to use the calculator?

→ Launch Calculator